Auxiliary feeding device for filling in rubber mold with energetic materials

A technology of feeding device and rubber mold, which is applied in the directions of transportation, packaging, loading/unloading, etc., can solve problems such as increased cleaning and spraying operation procedures, physical and mental health injuries of operators, powder leakage and dust, and achieves the improvement of intrinsic safety and professionalism Hygienic level, overcoming high labor intensity, uniform and controllable speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

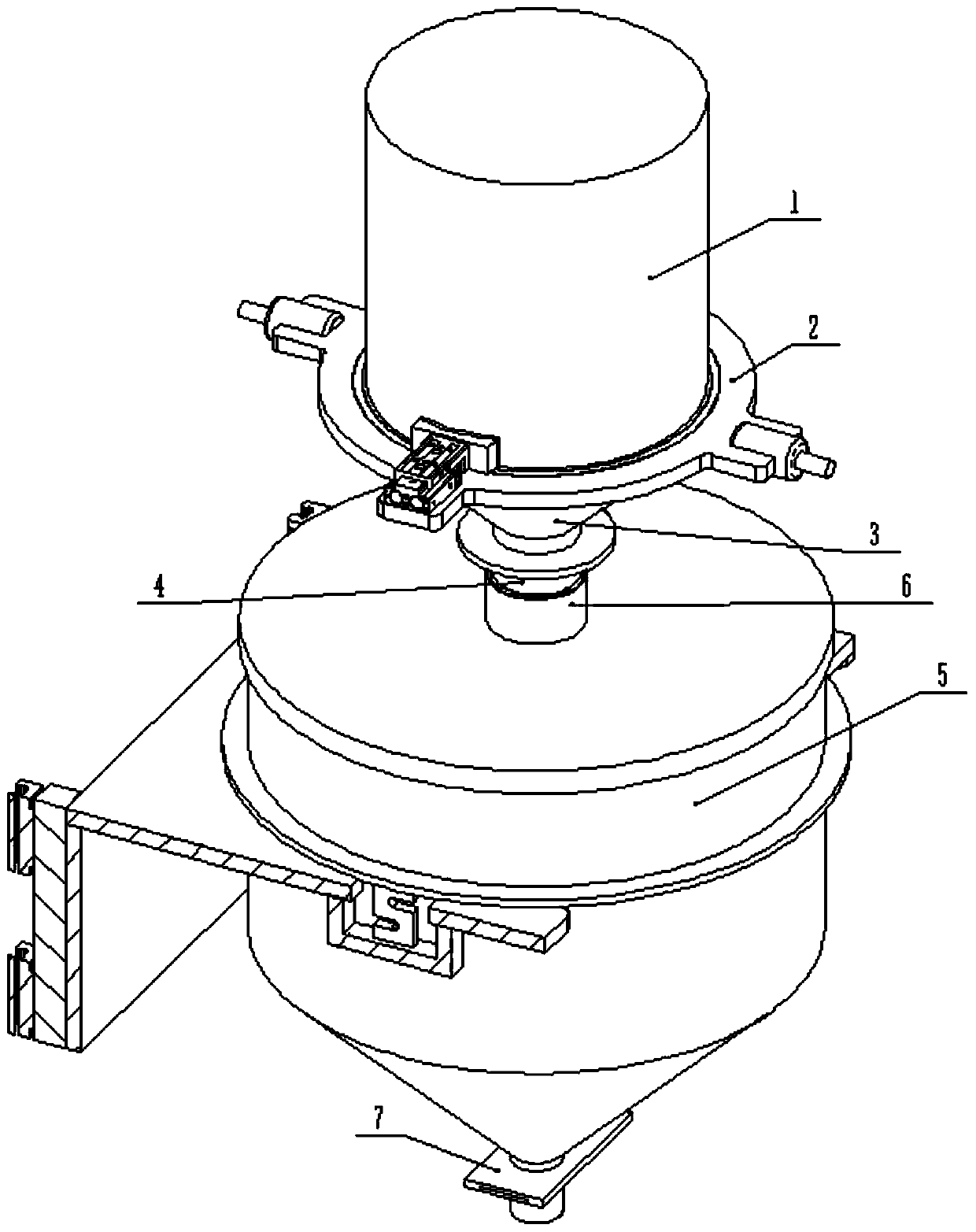

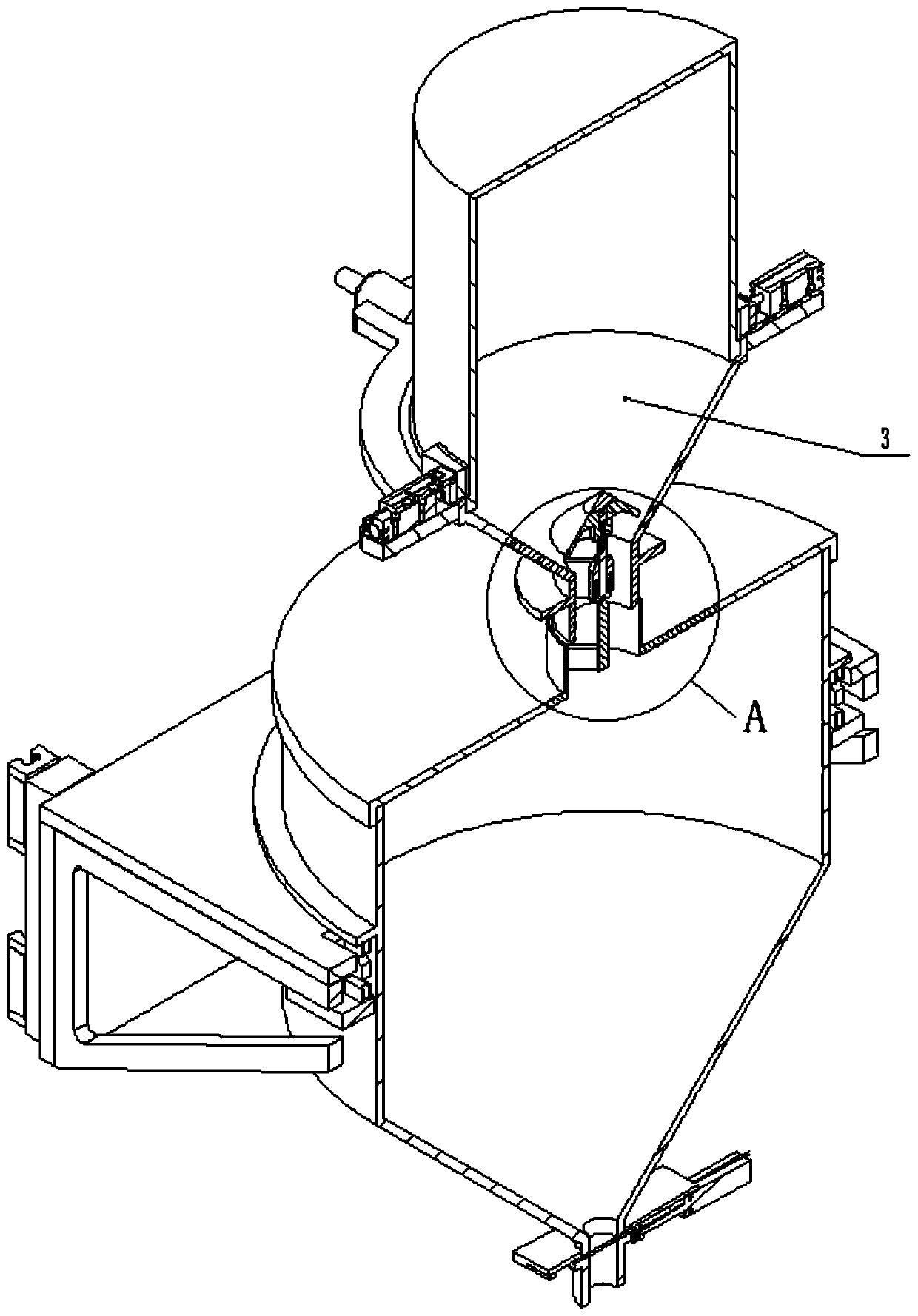

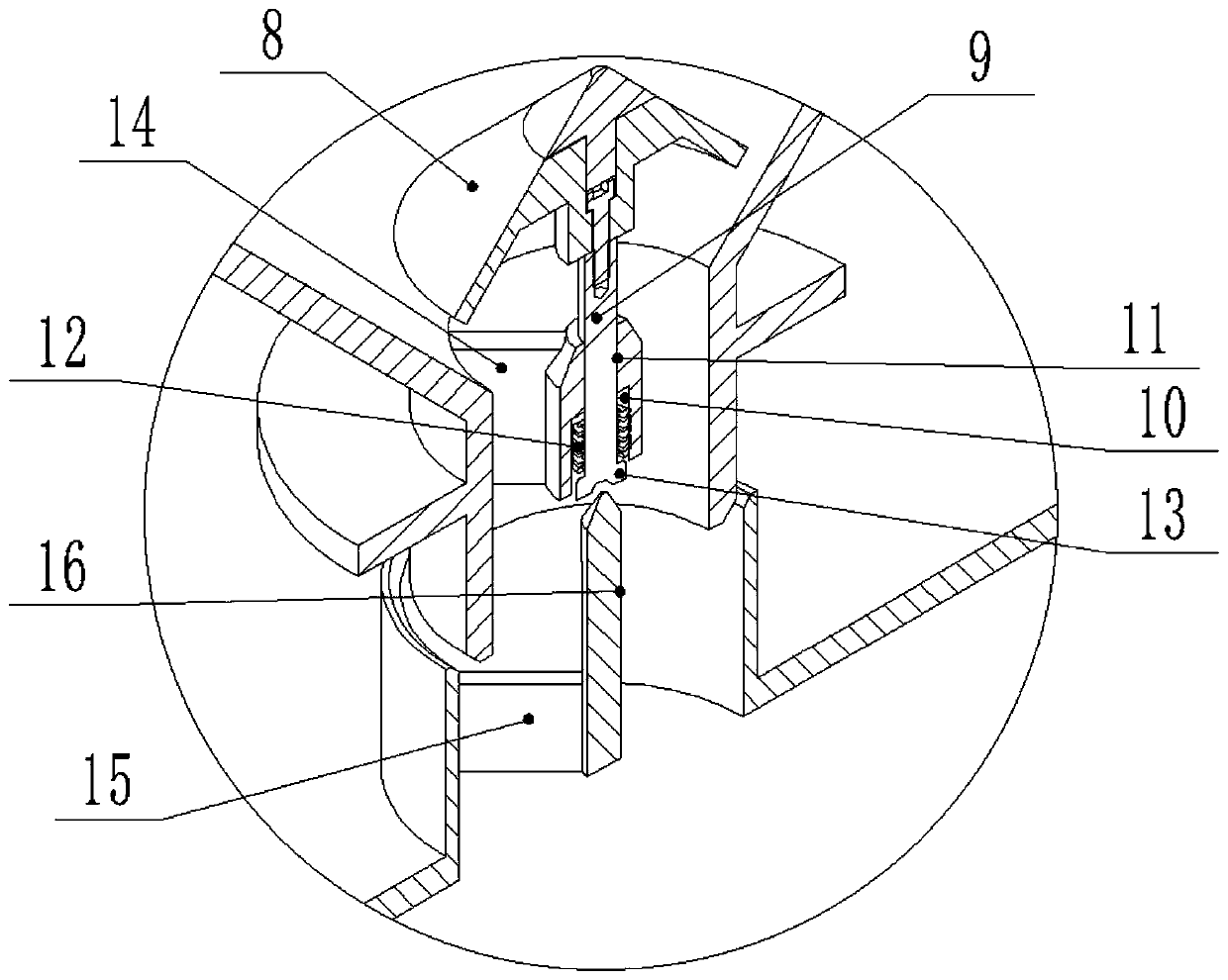

[0024] Such as Figure 1-3 As shown, an auxiliary feeding device for filling energetic materials in a rubber mold, the auxiliary feeding device includes a barrel positioning plate 2, a sealing cover 3 and a hopper 5, the barrel positioning plate 2 is in the form of a ring, and the material The inner ring of the barrel positioning plate 2 is used to fasten on the barrel 1, the discharge port of the barrel 1 is in sealing contact with the sealing cover 3, the sealing cover 3 is funnel-shaped, and the big end of the sealing cover 3 is in contact with the barrel positioning plate 2 Sealed connection, the small end of the sealing cover 3 is connected with a vertical discharge section 4, the vertical discharge section 4 is provided with a valve plate 8 assembly, and the valve plate 8 assembly includes a valve plate 8, a spring 12, a locking rod 9 and a guide fixed cavity, the guide fixed cavity is fixed on the side wall of the vertical discharge section 4, the locking rod 9 is slida...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com