Replacement device of protective liquid of water-treating membrane element and replacement method thereof

A water treatment membrane and protective liquid technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of high labor intensity, insufficient perfusion, incomplete draining, etc., to overcome the high labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

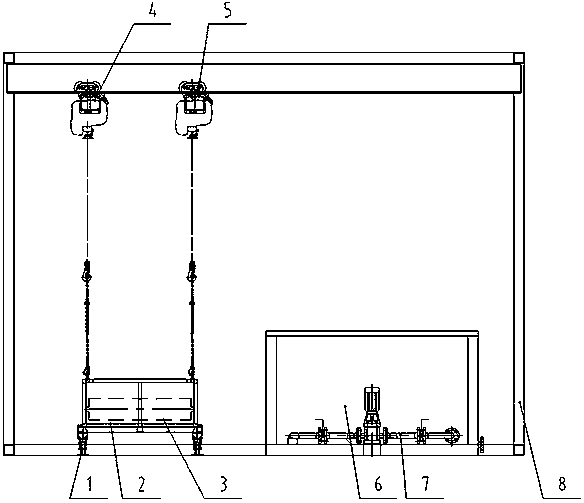

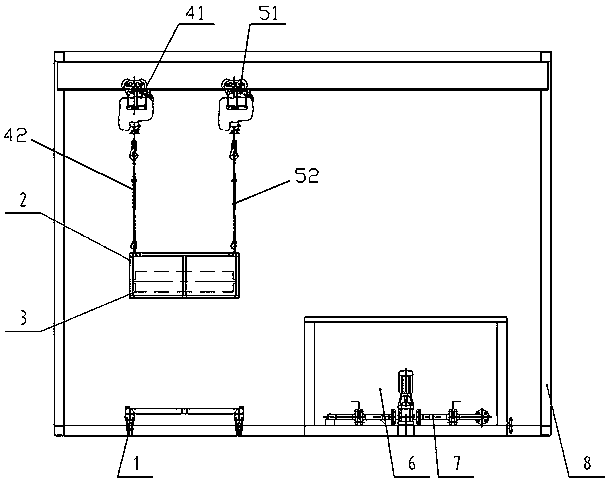

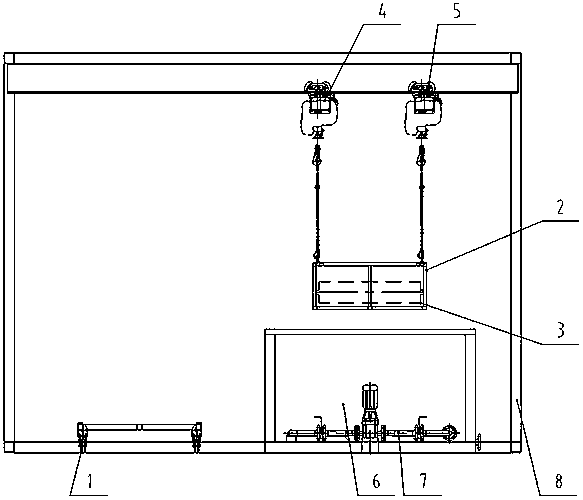

[0025] see Figure 1-Figure 6 , a water treatment membrane element protective liquid replacement device, including feeding and discharging trolley 1, material frame 2, front lifting trolley 4, rear lifting trolley 5, liquid storage tank 6, circulation system 7, replacement chamber 8 and fan 9.

[0026] The replacement chamber 8 is used for isolation to prevent the protection liquid from spreading into the workshop.

[0027] The feeding and discharging trolley 1 is mobile installed on the ground, and is used for feeding the material frame 2 and the water treatment membrane element 3 into and out of the replacement chamber 8 .

[0028] The material frame 2 is used to load water treatment membrane elements 3, and can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com