Automatic tension mechanism of oil pumping unit belt

A technology of tensioning mechanism and pumping unit, which is applied to belts/chains/gears, mechanical equipment, transmission devices, etc., can solve problems such as failure to work normally, reduced working efficiency of pumping units, and high labor intensity, and achieve automation and High precision, overcome the effect of high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

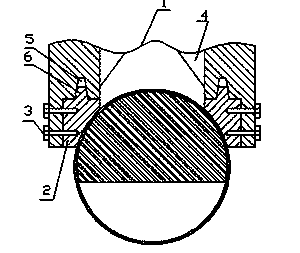

[0010] In the figure, this kind of pumping unit belt automatic tensioning mechanism includes: tensioner 1, axle 2, bracket 3, pressure sensor 4, guide rail 5, seat plate 6, connecting rod 7, screw sleeve 8, two-way screw 9, The stepping motor 10 , the bearing seat 11 , the transmission slider 12 , and the support slider 13 , the guide rail 5 is installed and fixed on the upper plane of the seat plate 6 , and the upper and lower ends of the guide rail 5 are respectively provided with a support slider 13 and a transmission slider 12 . , a pressure sensor 4 is arranged between the support slider 13 and the transmission slider 12, a bracket 3 is fixedly installed on the upper part of the support slider 13, and a tensioner 1 is installed at the top of the bracket 3 through the axle 2. On both sides of the seat plate 6 directly below the transmission slider 12, two bearing seats 11 are fixedly installed symmetrically, and two-way screw rods 9 are installed on the two bearing seats 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com