Frequency converter with reduced pre-charging time

A frequency converter and capacitor technology, applied in the field of frequency converters, can solve the problems of high cost, large overall volume, and long time support for capacitor precharging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

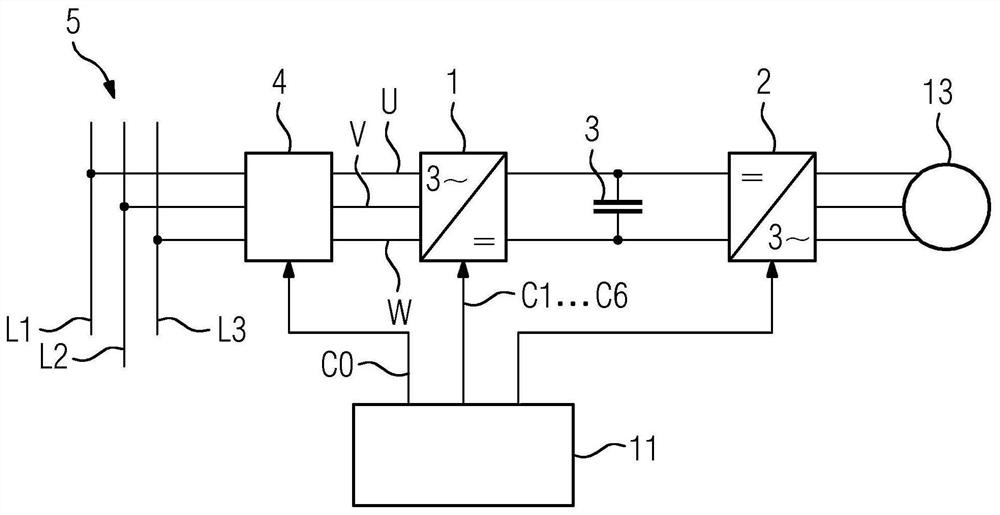

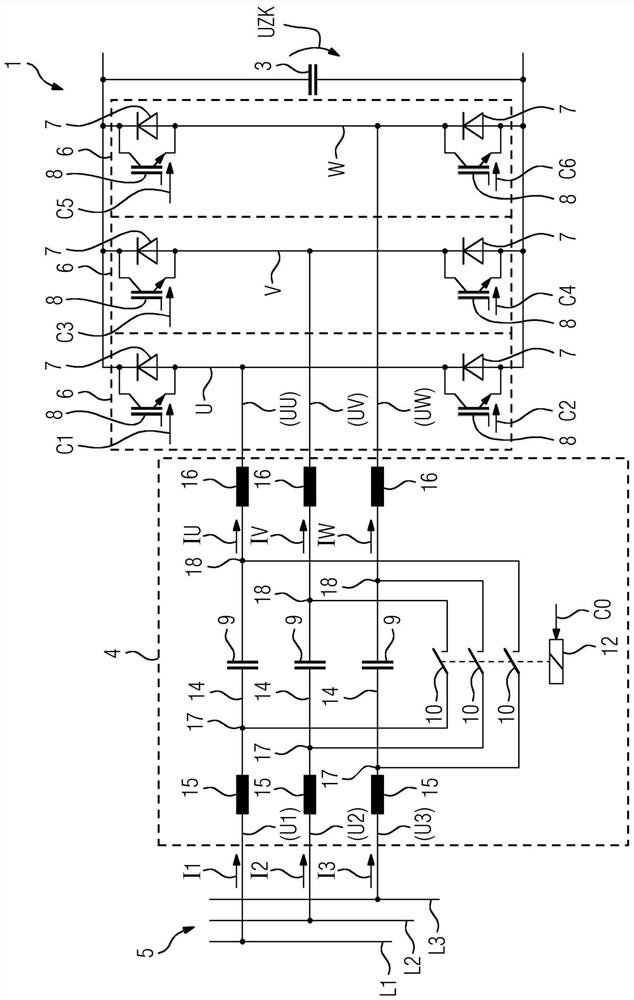

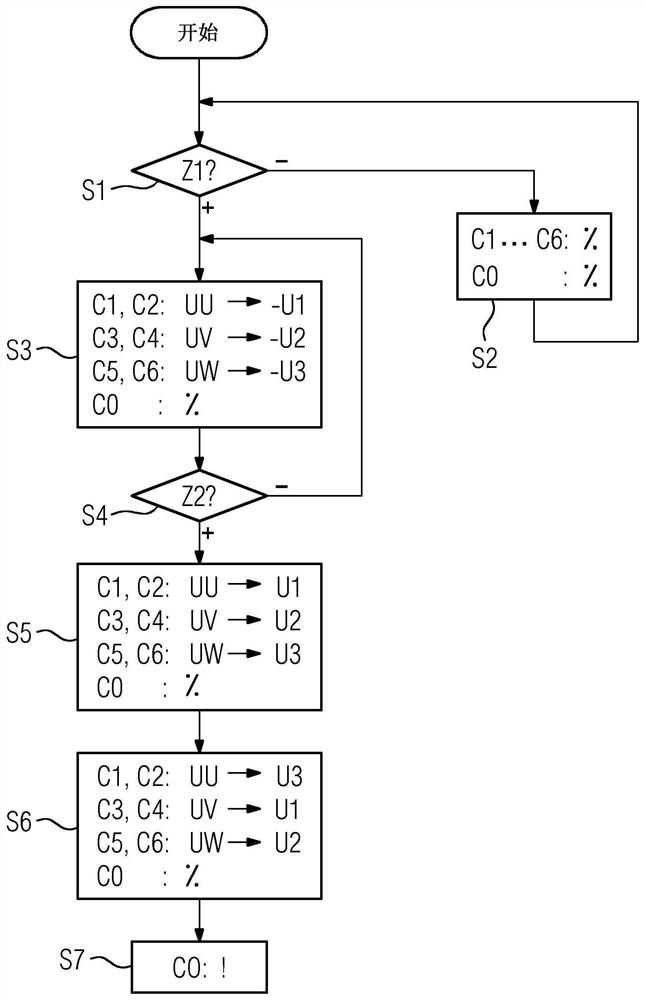

[0035] according to figure 1 , the frequency converter has a rectifier 1 on the input side. A further device 2 is arranged downstream of the rectifier 1 on the output side. The frequency converter also has at least one supporting capacitor 3 which is arranged between the rectifier 1 and the further device 2 . This further device is usually designed as an inverter. In this case it is an intermediate current converter. However, this further device can also be of a different design, for example as a direct current consumer, a direct current grid, a photovoltaic system or an energy store.

[0036] The rectifier 1 has U, V, W phases on the input side, which are connected via an upstream circuit 4 to the phases L1 , L2 , L3 of the supply network 5 . Both rectifier 1 and supply network 5 are therefore polyphase, that is to say they each have a plurality of phases U, V, W or L1 , L2 , L3 . The phases U, V, W of the rectifier 1 are referred to below as input-side phases U, V, W to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com