Forced pressure oxygenation type water body treatment equipment

A technology for treating equipment and water body, which is applied in the field of pressurized oxygen-increasing water body treatment equipment, which can solve the problems that it is inconvenient to ensure the oxygen content of the water body below the cleanliness of the reaction surface, so as to facilitate movement, increase dissolved oxygen, and strengthen strong oxidation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

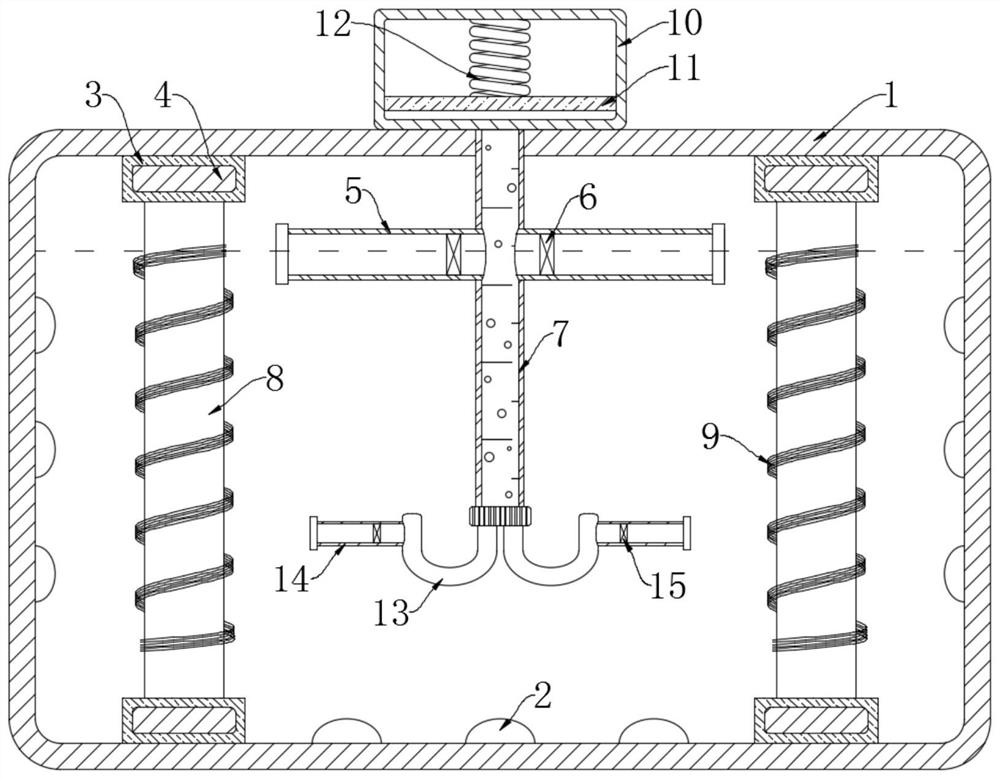

[0022] refer to figure 1 , a kind of pressurized oxygenation type water body treatment equipment, comprises treatment box 1, and a plurality of ultraviolet lamps 2 are installed in the treatment box 1, and a plurality of sealing boxes 3 are symmetrically installed on the inner top wall and the inner bottom wall of the treatment box 1, Each sealing box 3 is provided with an electromagnet 4, and a pulse current is passed into the electromagnet 4 when in use, and a purification column 8 is fixedly installed between the two coaxial sealing boxes 3, and the outer surface of the purification column 8 The surface is coated with a photocatalyst medium layer. Under the irradiation of ultraviolet light, the photocatalyst can show strong oxidation, thereby decomposing harmful substances, so as to achieve the effect of purification and sterilization. Each purification column 8 is wound with a conductive spring 9. The conductive spring 9 is wound with a flexible brush strip, which can clea...

Embodiment 2

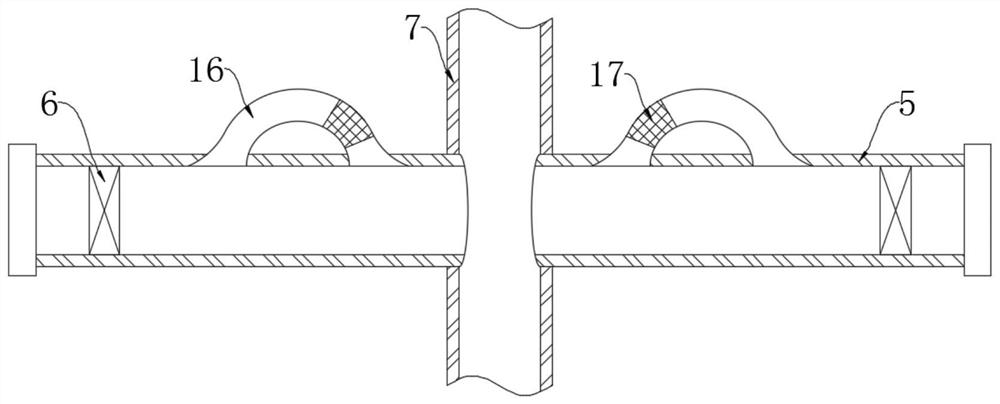

[0031] refer to figure 2 The difference between this embodiment and Embodiment 1 is that: each inlet pipe 5 is connected with an arched pipe 16, and each end of each arched pipe 16 near the transfer pipe 7 is equipped with a filter screen 17.

[0032] This embodiment can explain its functional principle through the following operation mode: when the magnetic plate 11 moves upward and sucks the sewage into the water inlet pipe 5, the flow velocity of the sewage is relatively high, and the fluctuation is obvious, so part of the sewage will pass through the arched pipe 16 to the transfer pipe 7 direction movement, the water flow will squeeze the air in the arched pipe 16 into the transfer pipe 7, thereby reducing the probability of air escaping the water flow, so that more air can be transported to the sewage area at the bottom. When the air passes through the filter screen 17, the filter The net 17 will divide the air into a plurality of small air bubbles before the sewage ente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com