Flexible cable threading mechanism

A flexible cable and cable technology, which is applied to the parts and packaging of strapping machines, can solve the problems of low efficiency of manual production methods, and achieve the effects of compact structure, wide application range and high degree of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

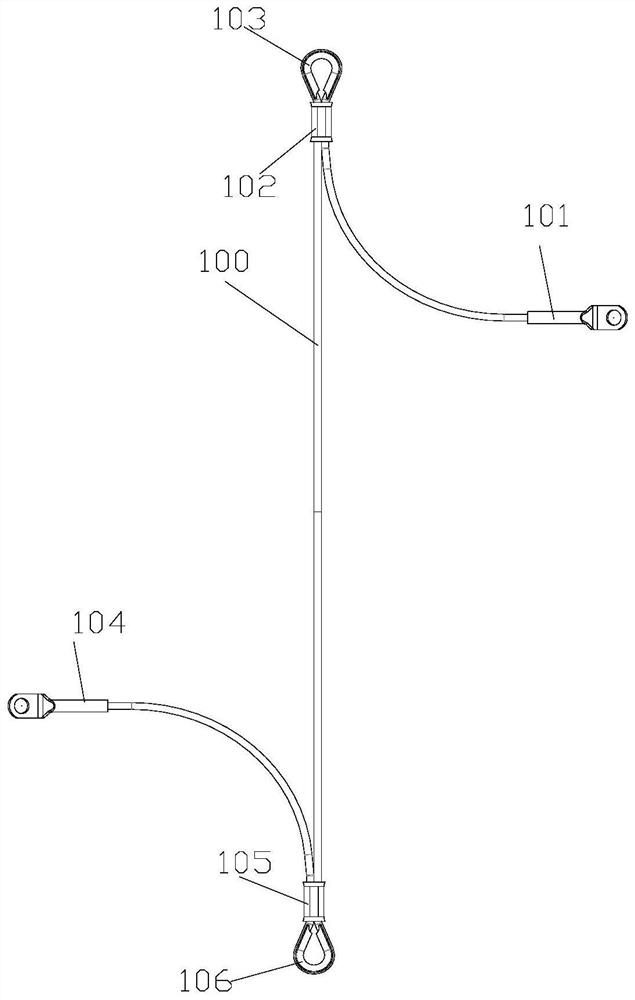

[0024] For the flexible cable threading mechanism of the present invention, it can be tightened or compressed after the flexible cable is coiled. For example, the suspension string on the high-speed rail, such as figure 1 The suspension string product includes a suspension string 100, the two ends of the suspension string 100 are respectively covered with a first terminal 101 and a second terminal 104 with the same structure, and the suspension string 100 near one end of the first terminal 101 is wound around the second terminal on a heart-shaped ring 103, and is compressed by the first crimping tube 102, and the suspension string 100 near one end of the second terminal 104 is wound on the second heart-shaped ring 106, and is compressed by the second crimping tube 105, Likewise, the first heart-shaped ring 103 and the second heart-shaped ring 106 have the same structure, and the first crimping tube 102 and the second crimping tube 105 have the same structure.

[0025] Or it c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap