Seismic mitigation and isolation structure of bridge body

A technology of vibration reduction and isolation and beam body, which is applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of inconvenient installation, difficulty in meeting the sliding requirements of bearings, insufficient bearing capacity, etc., and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Preferred embodiments of the present invention will be described in detail below.

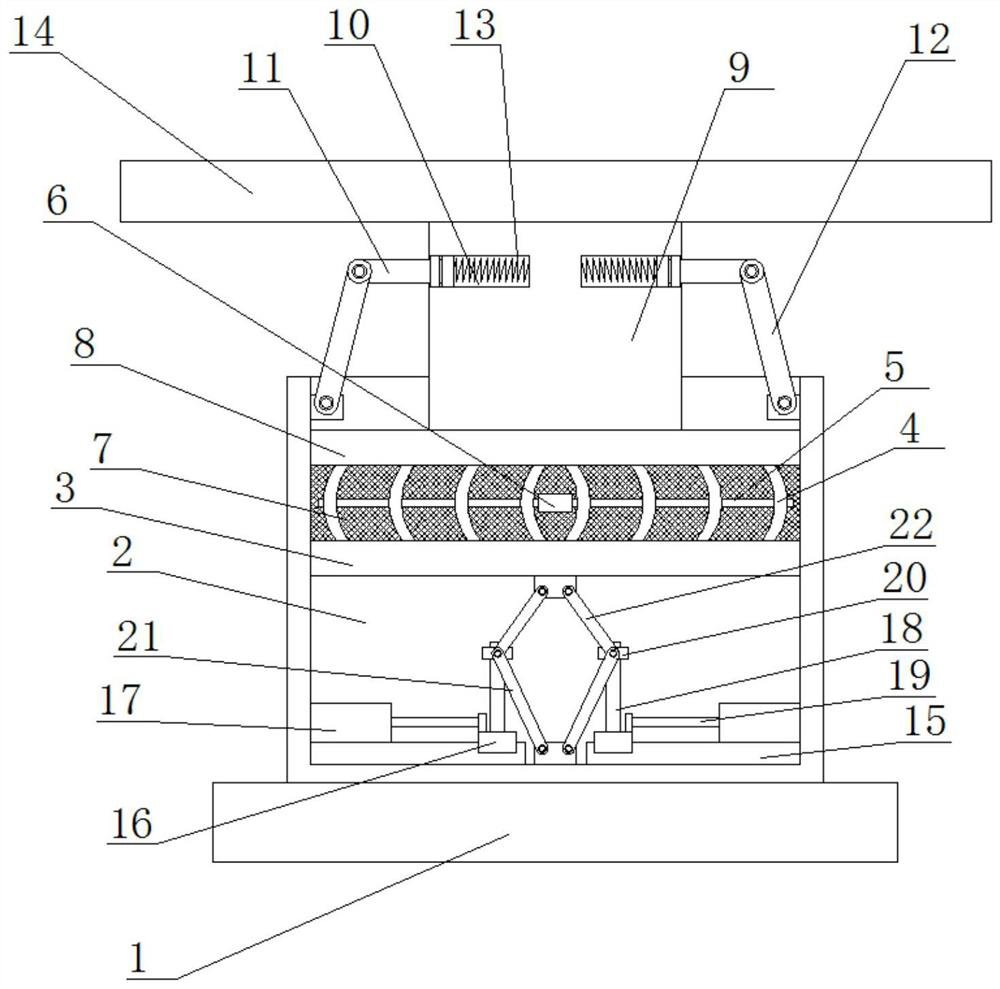

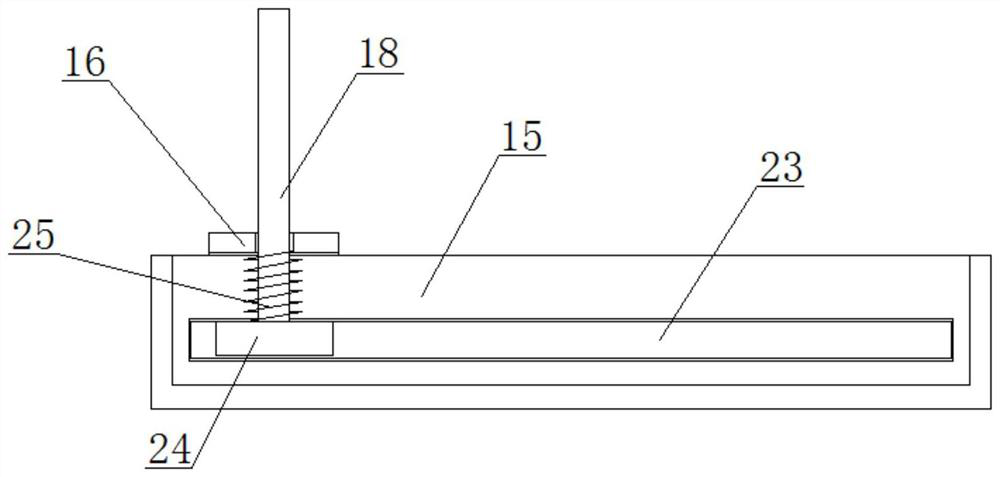

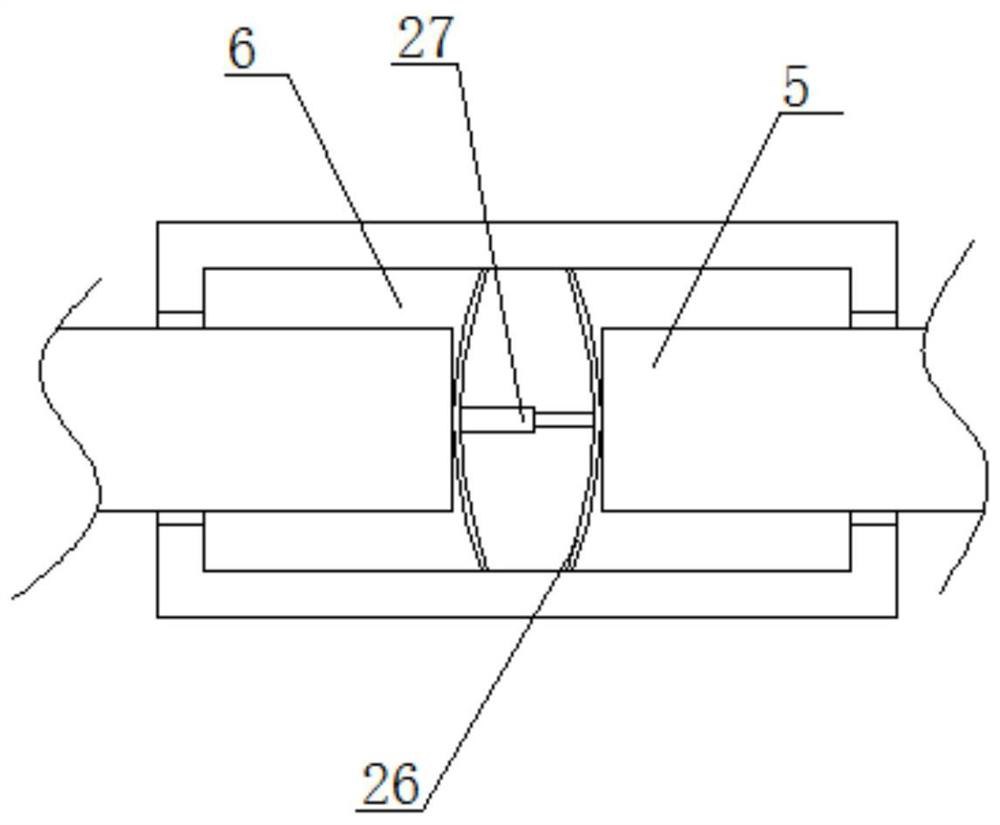

[0029] The reference signs in the drawings of the specification include: 1 base, 2 installation cover, 3 support plate, 4 curved steel plate, 5 buffer rod, 6 connection box, 7 shock-absorbing cotton, 8 fixing plate, 9 support column, 10 connection groove , 11 connecting rod, 12 supporting rod, 13 buffer spring, 14 mounting plate, 15 sliding cover, 16 sliding plate, 17 buffer box, 18 screw rod, 19 push rod, 20 nut, 21 rotating rod, 22 pressure rod, 23 rack, 24 gears, 25 torsion springs, 26 connecting steel plates, 27 buffer hydraulic rods, 28 moving boxes, 29 return plates, 30 return springs, 31 sealing plates.

[0030] Such as Figure 1-5 The shock-absorbing and isolating structure of a bridge girder shown includes a base 1, a mounting cover 2 is fixedly installed on the top of the base 1, and a support plate 3 is slidably connected to the inside of the mounting cover 2, and the top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com