Yield anchor cable spherical rotating and aligning device

A ball center and anchor cable technology, which is applied in the installation of bolts, mining equipment, earthwork drilling and mining, etc., can solve the problems of greatly reduced prestress, uncontrollable deformation of surrounding rock, and inconspicuous gradual pressure relief, etc. The effect of small stress concentration, long service life, and obvious yielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and examples, but it should be understood that the protection scope of the present invention is not limited to the contents described in the examples.

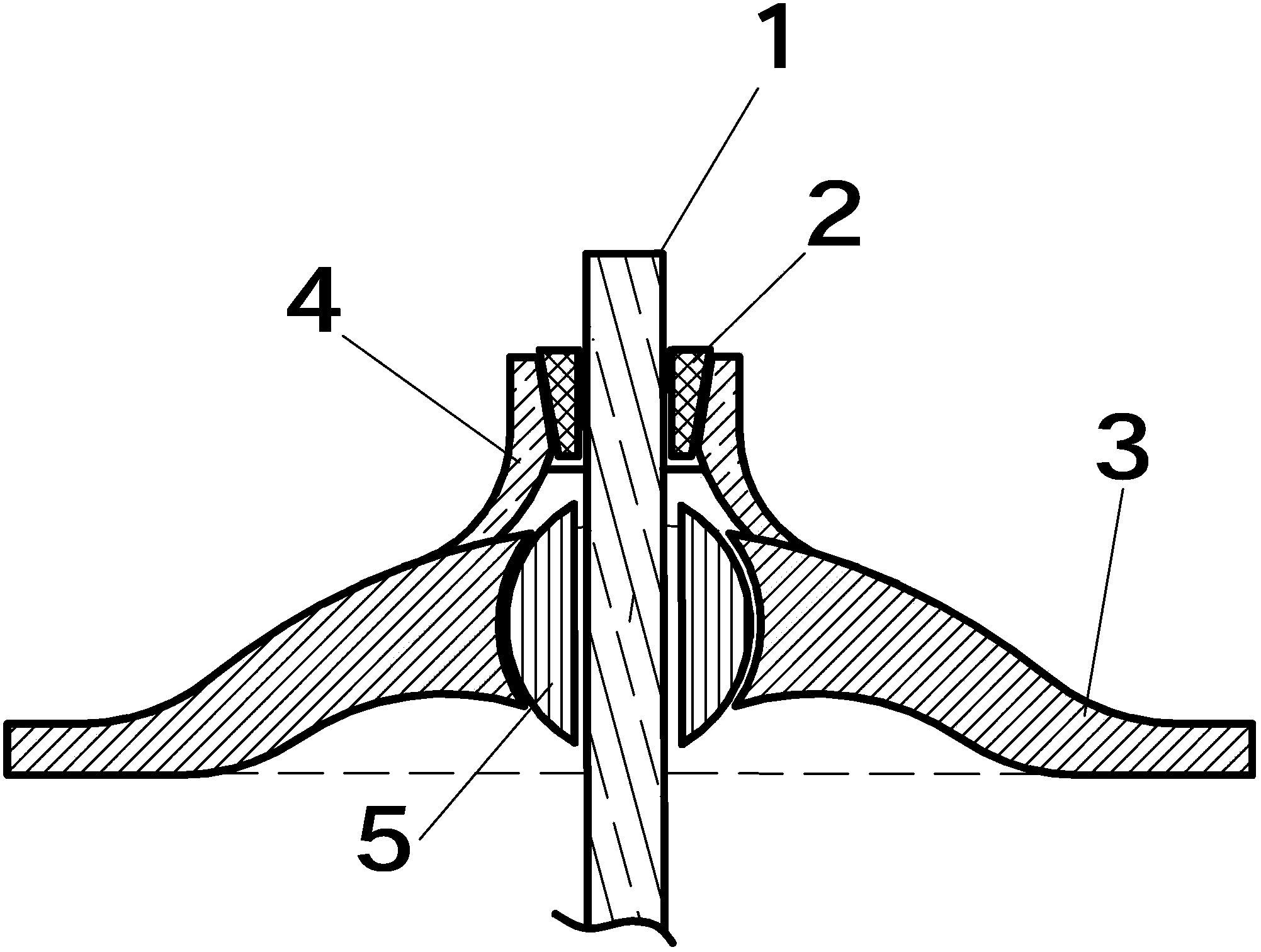

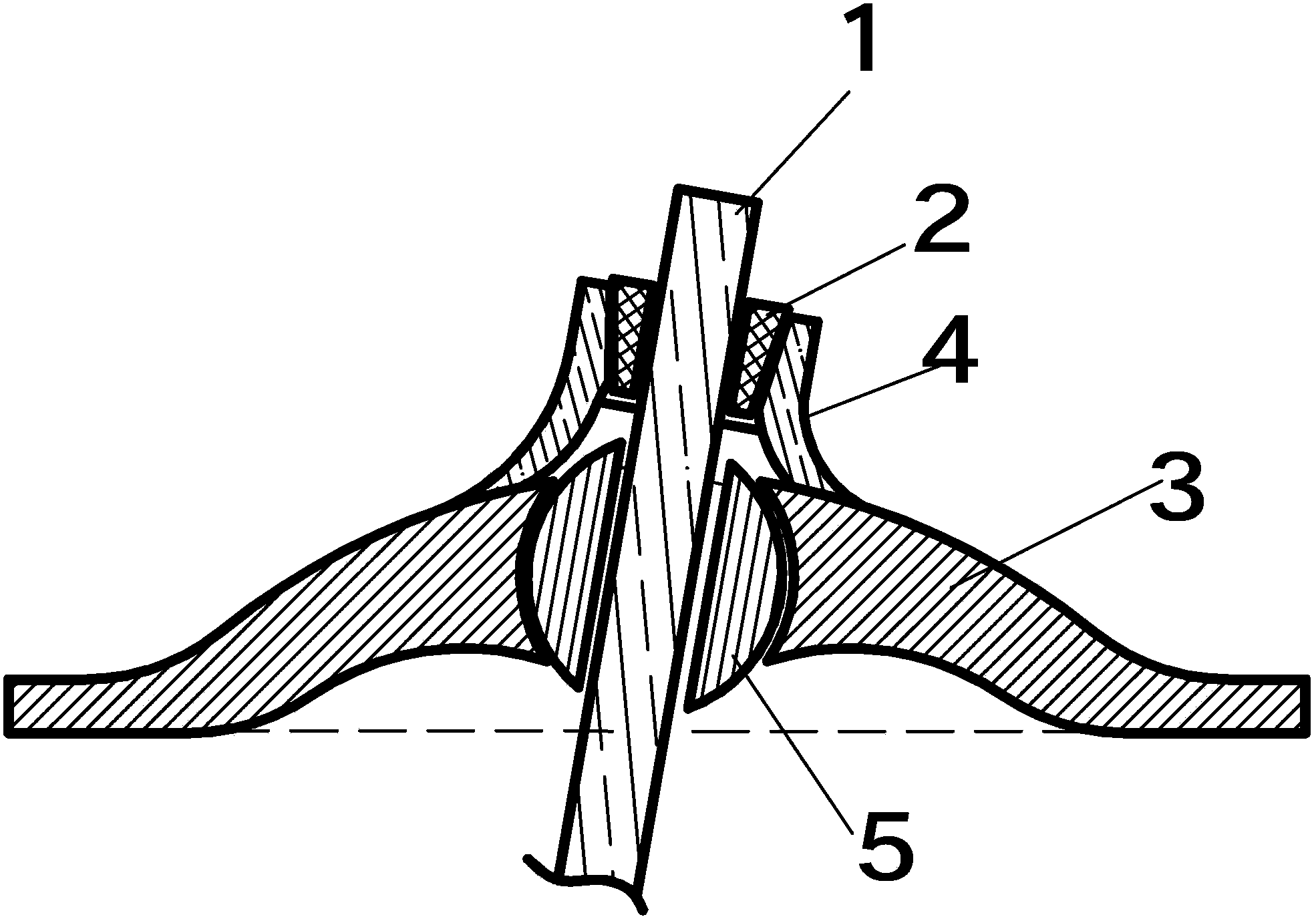

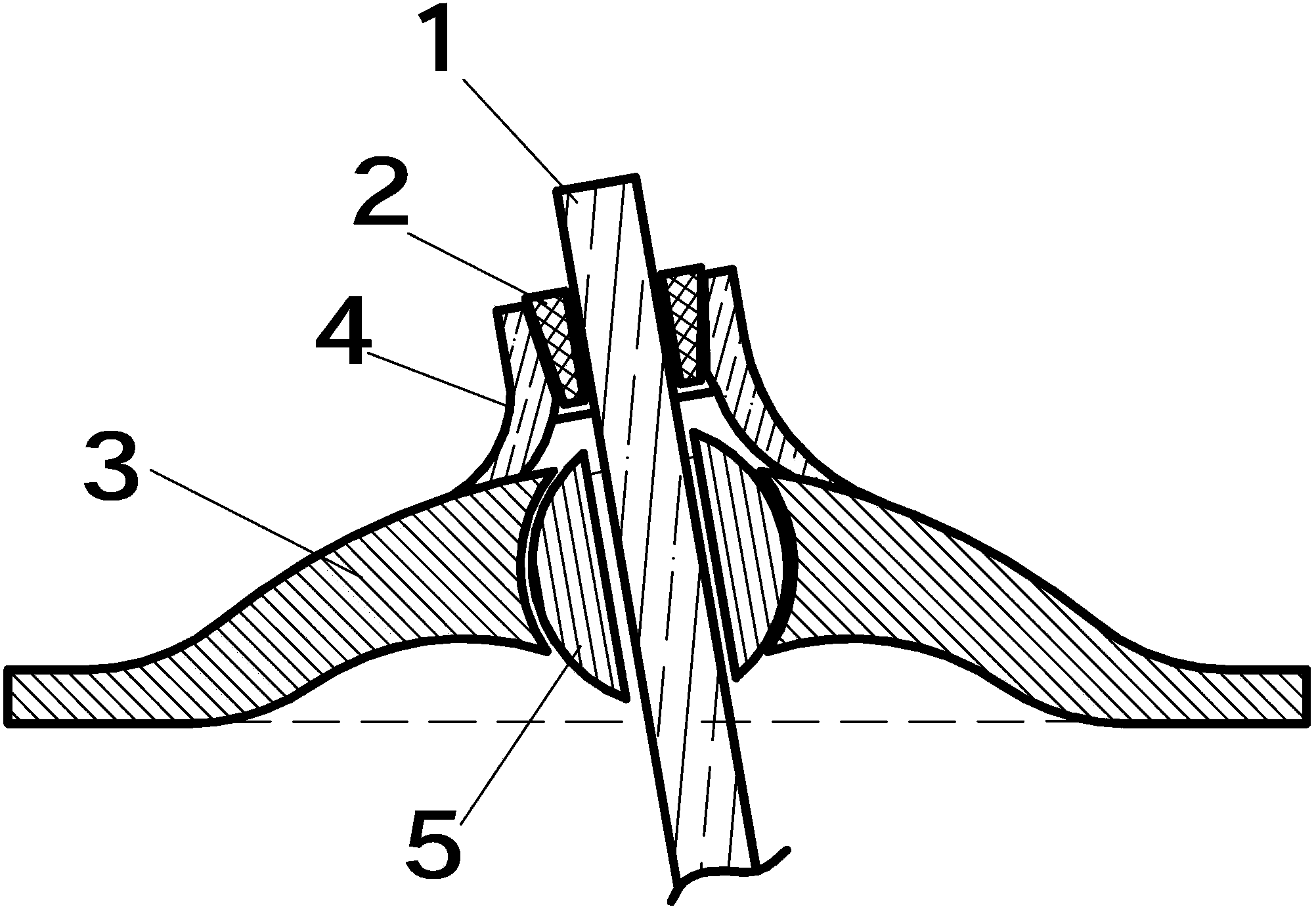

[0022] A spherical rotating centering device for pressing an anchor cable, comprising a hemispherical tray 3 , an anchor ring 4 , an anchor clip 2 and a center roller 5 . The above-mentioned hemispherical tray includes a tray body that is approximately hollow and hemispherical. The periphery of the tray body is provided with an annular flat bottom surface for contacting the wall of the roadway. The wall thickness of the tray body gradually increases from the edge to the center. A spherical groove is arranged in the center, and the spherical roller is placed in the spherical groove, and can freely rotate in the spherical groove, and the spherical roller is provided with a cylindrical axis hole. The above-mentioned anchor r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com