Height and span-adjustable support chassis for gas turbine

A gas turbine and span technology, which is applied in the direction of gas turbine devices, mechanical equipment, jet propulsion devices, etc., can solve the problems of supporting underframes with different heights and spans, and achieve the effect of reducing installation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

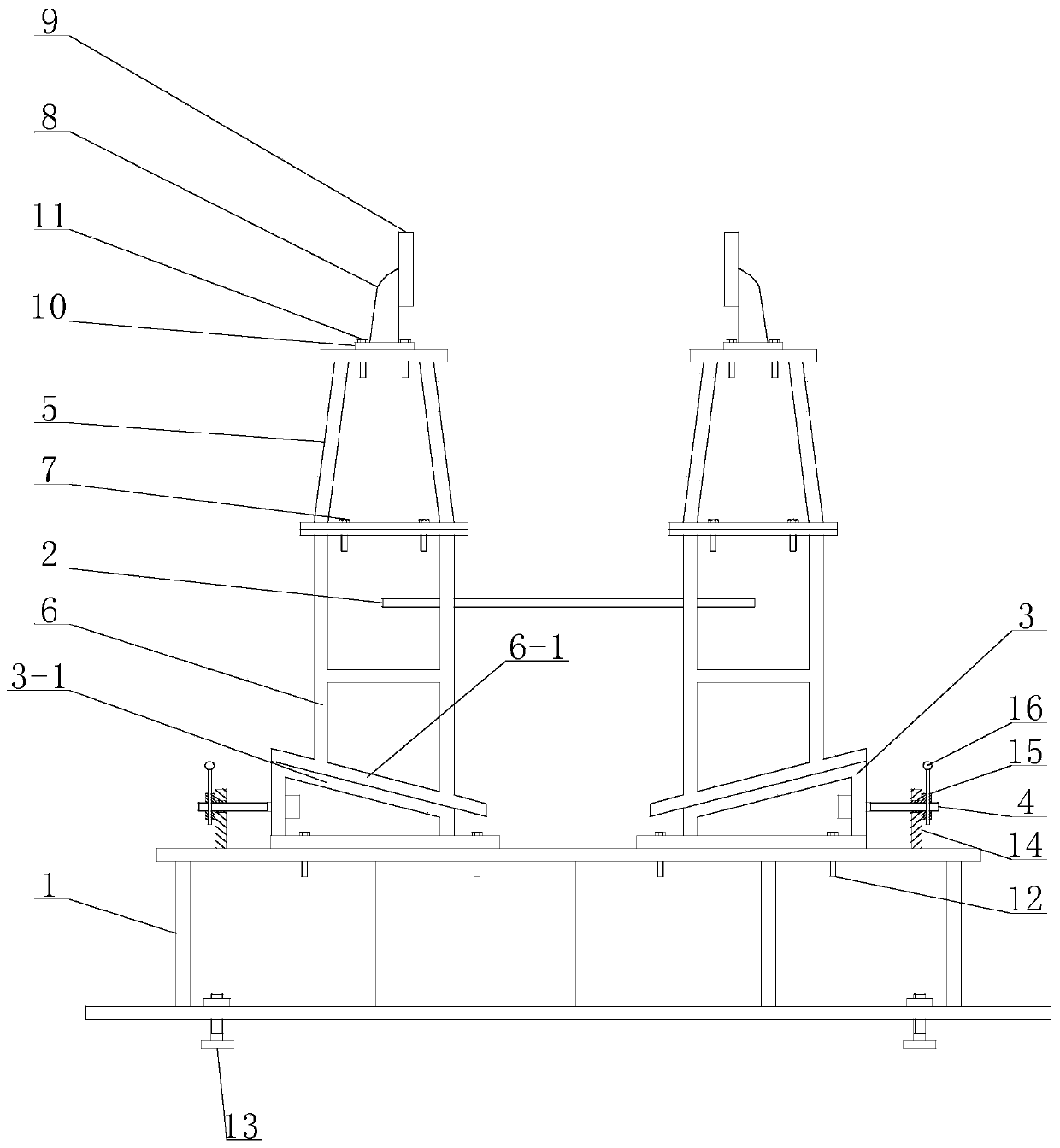

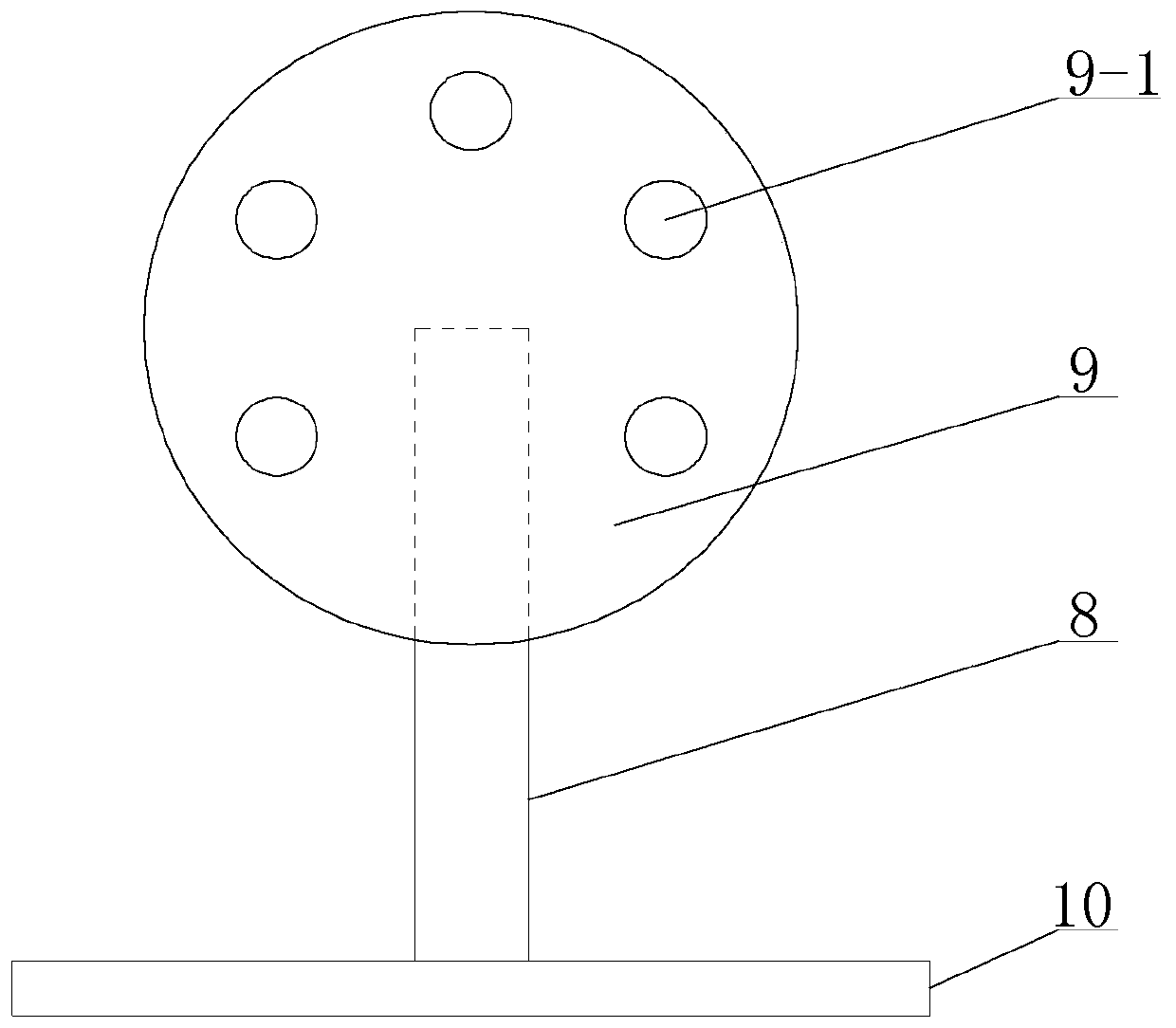

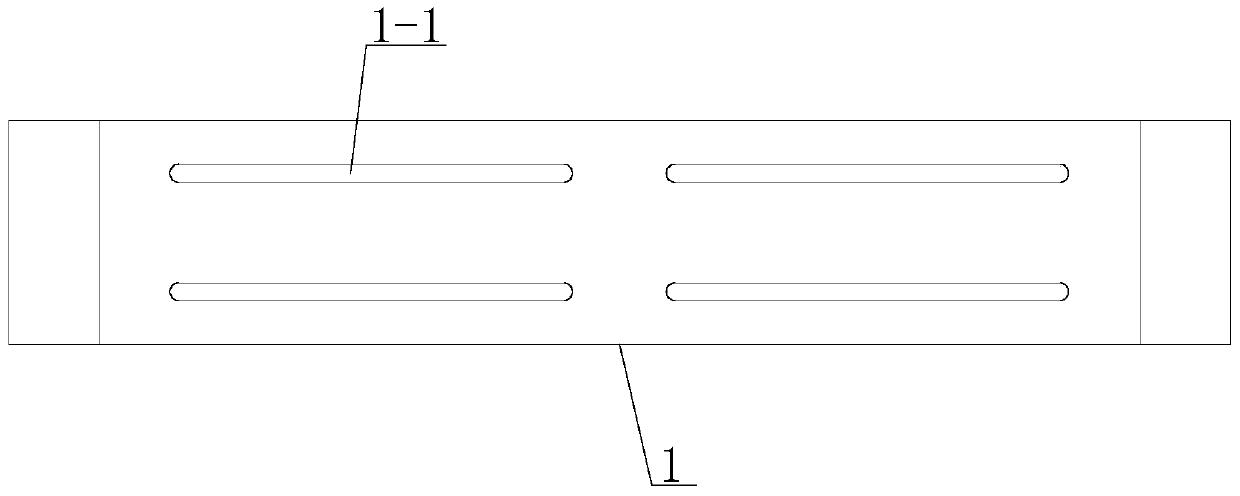

[0015] Specific implementation mode one: combine Figure 1 to Figure 3 Describe this embodiment, a gas turbine adjustable height and span support chassis, which includes a base 1, this embodiment also includes a span adjustment screw 2, two box assemblies, two Connection assembly, two adjustment boxes 3 and two height adjustment assemblies, the two adjustment boxes 3 are installed on the upper surface of the base 1 along the length direction of the base 1, and each adjustment box 3 can be adjusted along the upper surface of the base 1 Reciprocate in a straight line in the length direction of the length direction, and the two box assemblies are installed on two adjustment boxes 3 respectively, and the outer surfaces of each adjustment box 3 are respectively connected with one of the height adjustment assemblies, and the span adjustment lead screw 2. It is arranged horizontally between the two box assemblies, and the two ends of the span adjustment lead screw 2 are respectively ...

specific Embodiment approach 2

[0017] Specific implementation mode two: combination Figure 1 to Figure 3 To illustrate this embodiment, each of the box assemblies of a height- and span-adjustable support chassis for a gas turbine in this embodiment includes a small box 5, a large box 6, and a plurality of first bolts 7, The small box body 5 and the large box body 6 are stacked successively from top to bottom, and the bottom surface of the small box body 5 and the top surface of the large box body 6 are detachably connected by a plurality of first bolts 7; There is an upper slope 6-1, and the bottom of the adjustment box 3 is provided with a lower slope 3-1 matched with the upper slope 6-1, and the upper slope 6-1 fits with the lower slope 3-1; each of the height adjustment The assembly includes a height adjustment lead screw 4, a lead screw base 14, a nut 15 and a rocker 16, the lead screw base 14 is fixedly installed on the upper surface of the base 1, the nut 15 is embedded in the lead screw base 14, and...

specific Embodiment approach 3

[0021] Specific implementation mode three: combination Figure 1 to Figure 3 Describe this embodiment, the small box body 5 of the support chassis with adjustable height and span described in this embodiment is a trapezoidal box whose outer contour gradually expands from top to bottom, and the large box 6 is a rectangular box. box. Other components and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com