A Precise Control Method of Electric Actuator Based on Nonlinear Modeling

An electronically controlled actuator and precise control technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problem of inaccurate description and prediction of nonlinear force, high calculation performance requirements, and model fitting Large deviation and other problems, to achieve the effect of reducing calculation time, improving control performance, and reducing expected error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

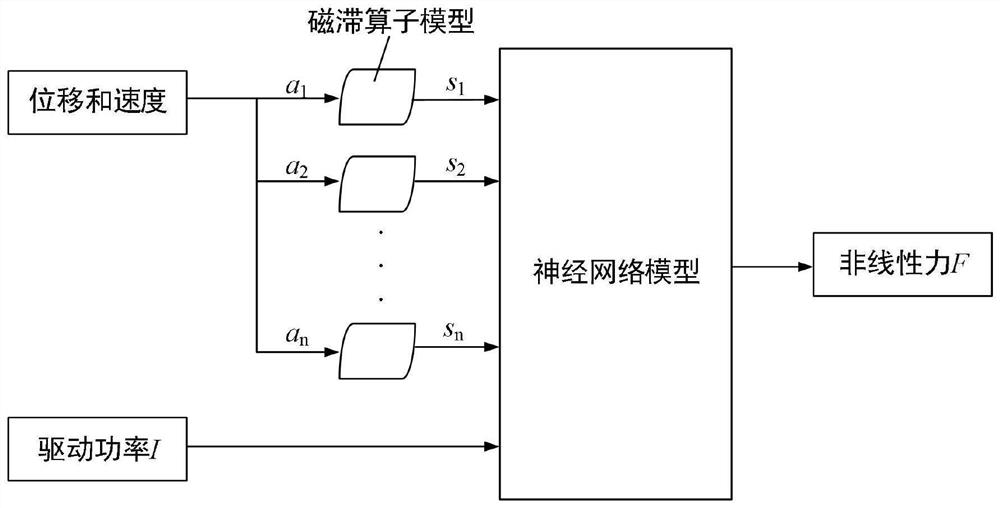

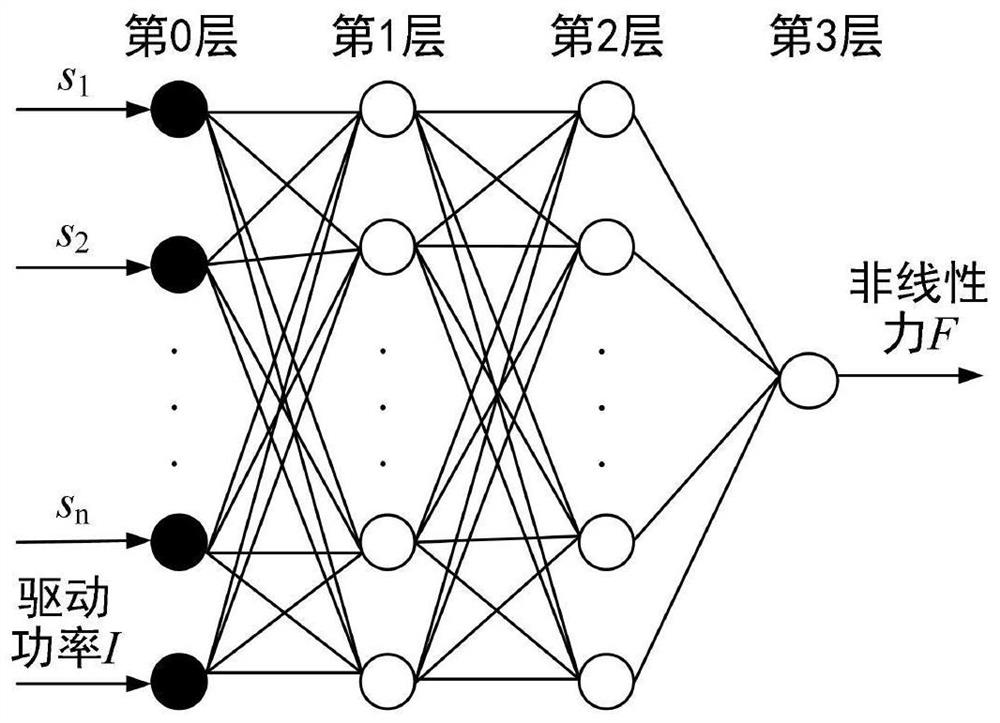

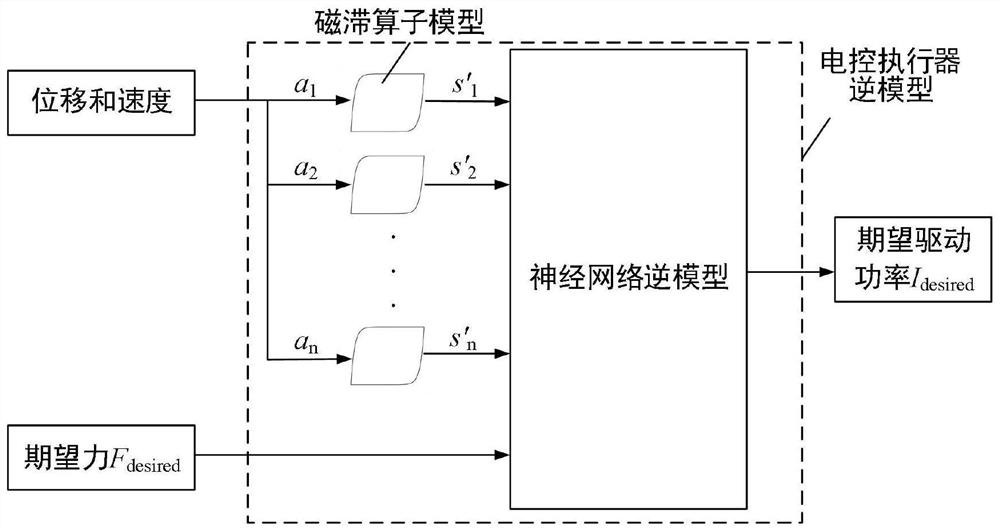

[0075] In this embodiment, a method for precise control of an electronically controlled actuator based on nonlinear modeling specifically includes establishing a hysteresis operator model, a neural network model, a nonlinear model of the electronically controlled actuator, an inverse model of the electronically controlled actuator, and Linearized control applications for electronically controlled actuators. In this example, refer to Figure 4 , the linearization control of electronically controlled actuators is applied to vehicles containing suspension systems, including: frame 1, displacement sensors 2, electronically controlled actuators 3, axles 4, tires 5; displacement sensors 2 are installed on the vehicle frame 1 to collect the displacement and velocity signals of the electronically controlled actuator 3; specifically, a precise control method for electronically controlled actuators based on nonlinear modeling, such as figure 1 As shown, proceed as follows:

[0076] St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com