Bearing table and laminating device

A technology of bearing platform and bearing groove, which is applied in the direction of identification devices and instruments, can solve problems such as non-adjustable lamination pressure and lamination angle, easy occurrence of air bubbles, and influence on display effect, so as to improve display effect and avoid air bubbles and black spots. spot, improve the effect of fit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

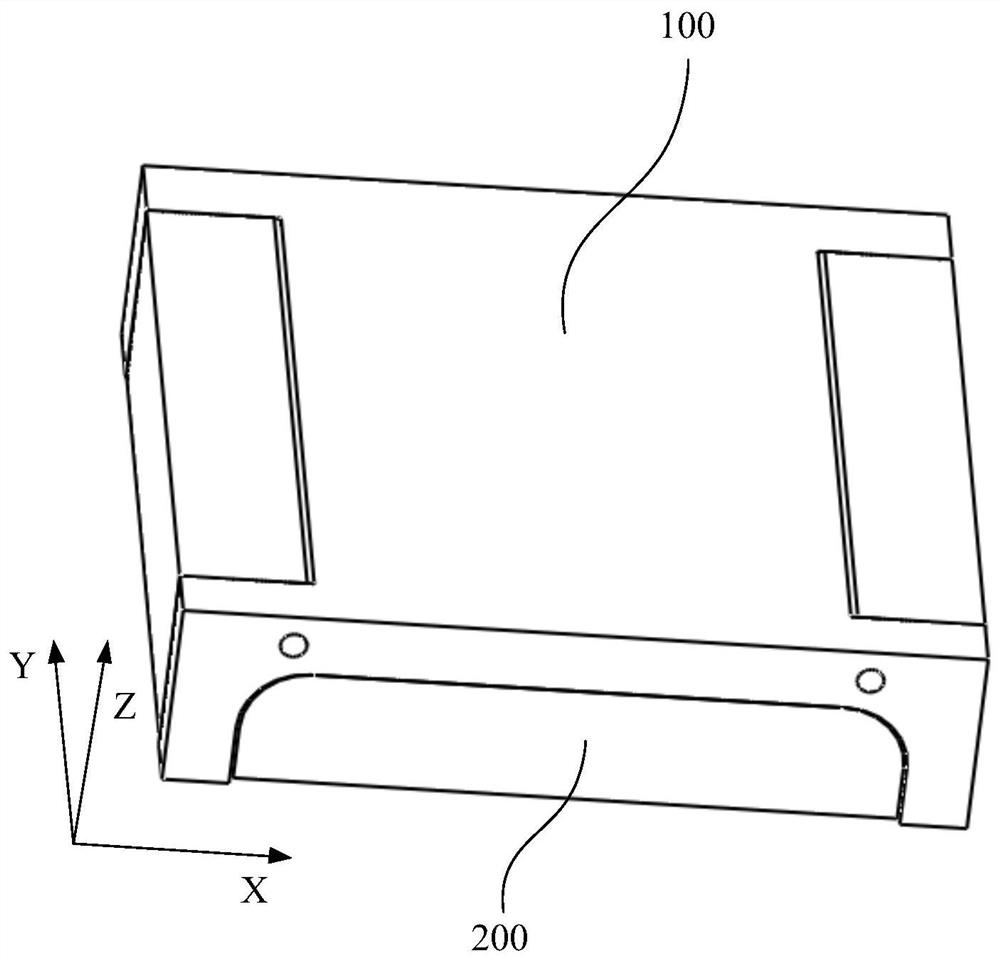

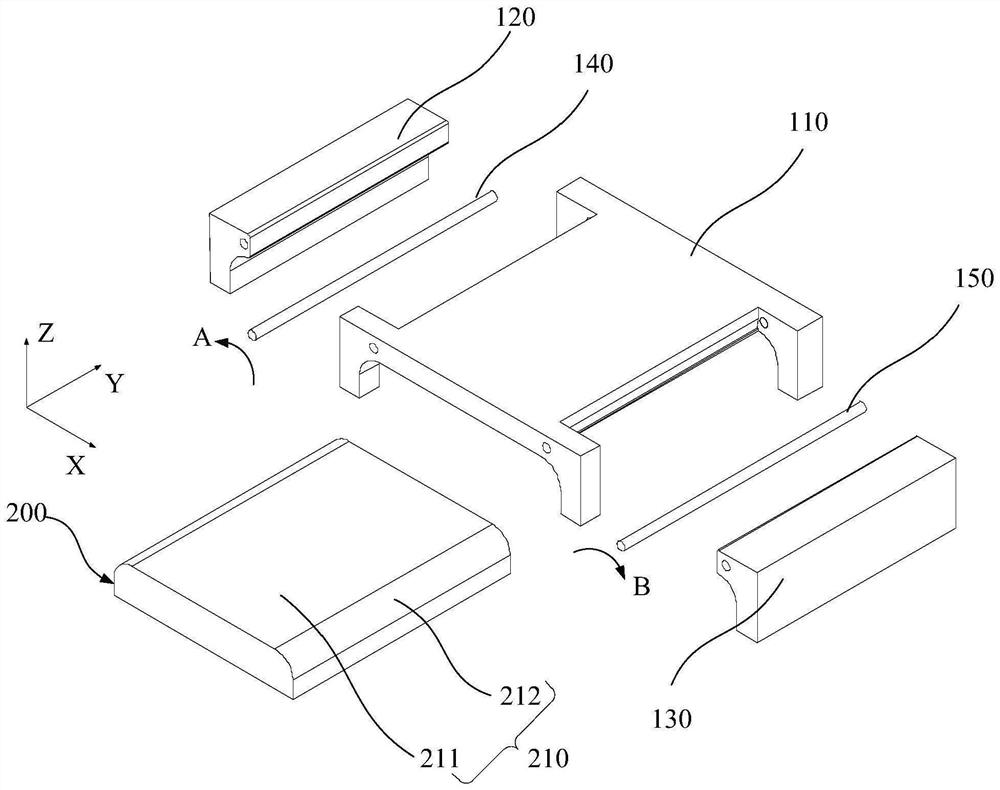

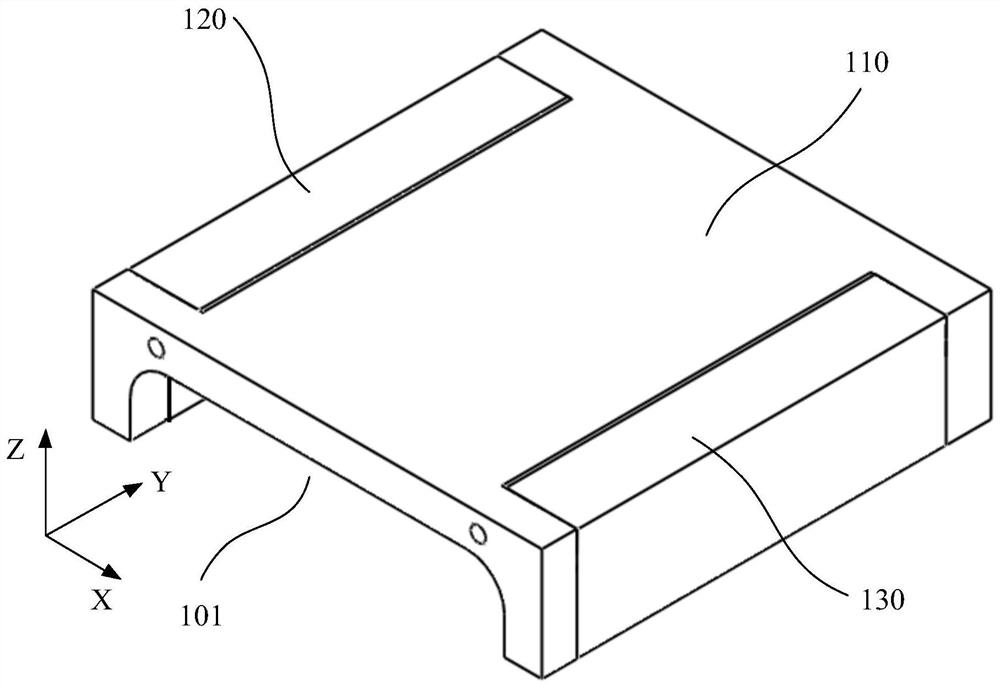

[0037] The development of flexible display technology has promoted the continuous innovation of consumer electronic product design. Due to its beautiful appearance, curved surface electronic products can also be displayed or touched on the front and side, with better space utilization and operational performance. And more favored by consumers. In the prior art, the flexible screen is generally bonded to the curved cover by a bonding device. The existing bonding device includes a fitting body and a bearing platform, on which a curved cover is fixed, and a flexible screen is arranged on the fitting body, and the flexible screen and the curved cover are bonded by extrusion of the bearing platform and the fitting body.

[0038] However, the bonding pressure and bonding angle at the curved surface of the bonding body and the bearing table cannot be adjusted. If the bonding pressure is too small or the bonding angle does not correspond, air bubbles or stress concentration will easil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com