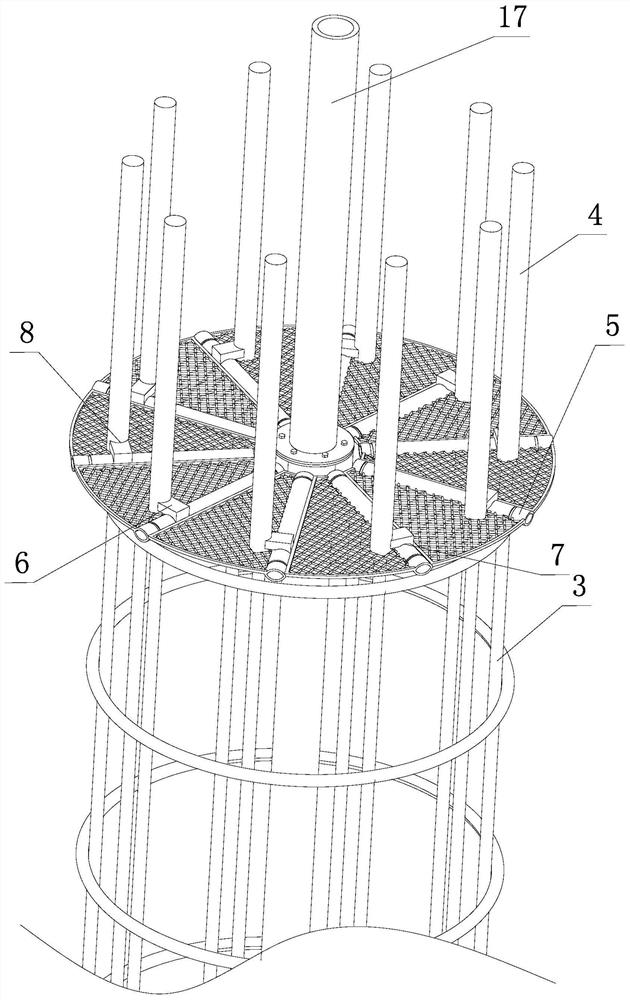

The Rapid Breaking Structure of the Overfilling Part on the Top of Cast-in-situ Pile

A technology of cast-in-situ piles and pile tops, which is applied in foundation structure engineering, foundation structure tests, sheet pile walls, etc., and can solve problems such as poor economy, damage, and huge labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

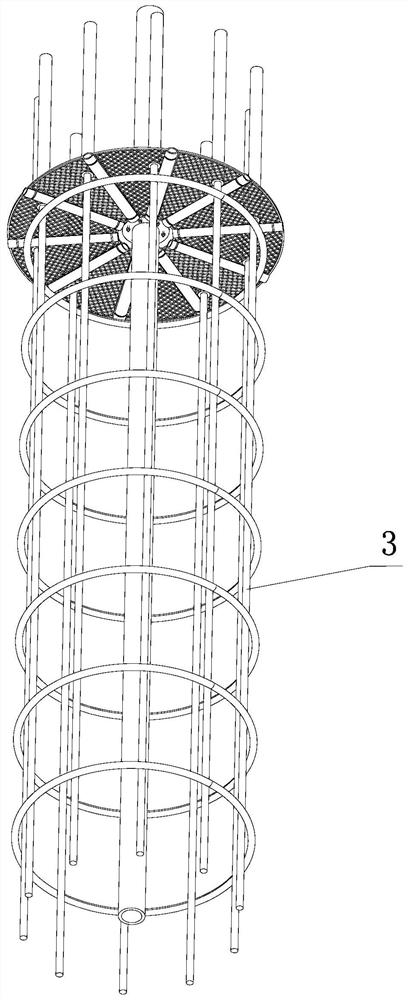

Method used

Image

Examples

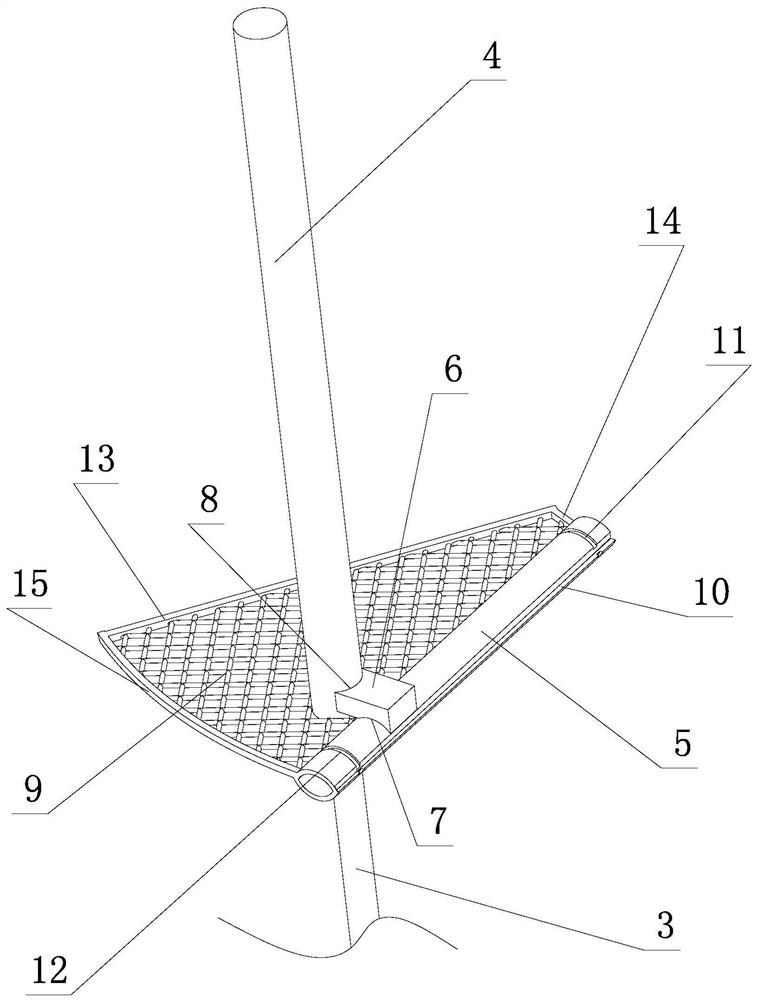

Embodiment Construction

[0024] One side of each longitudinal sleeve 4 is correspondingly provided with a transverse sleeve 5 and a hot melt block 6. The cross section of the transverse sleeve 5

[0029] The fan ring filter screen 9 is provided with a pressure sensor. It is known from common sense that the pressure sensor consists of a data line and a

[0031] Of course, after the overfilling part 1 of the present application is split, an anchoring ring 18 is embedded in the top of the overfilling part 1. easy to

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com