Automobile seat cloth with good air permeability

A car seat and air permeability technology, applied in seat covers, vehicle parts, layered products, etc., can solve the problems of reducing user comfort, poor resilience, and inability to gas, and achieve accelerated gas circulation and improvement. Moisture-proof performance, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

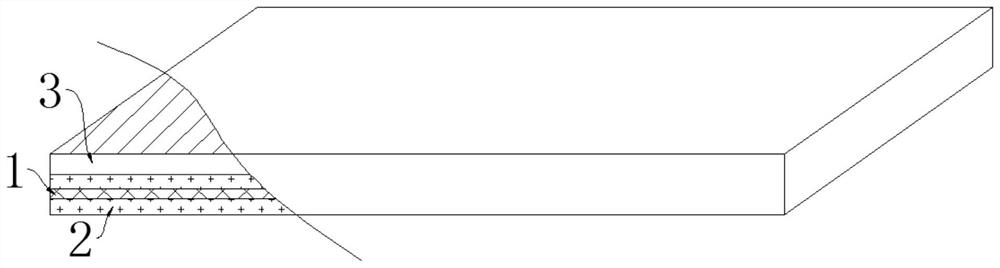

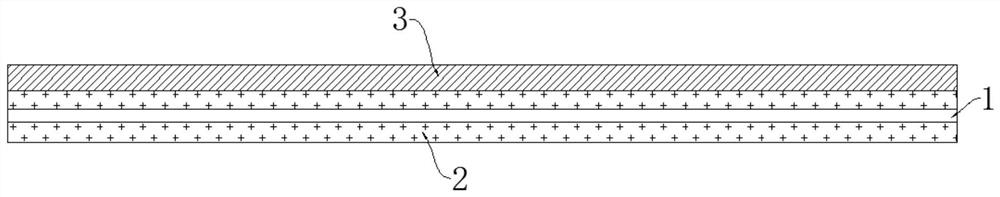

[0021] Such as Figure 1-5 As shown, the present invention provides a technical solution: a car seat fabric with good air permeability, including a base layer 1, two sets of breathable components 2 and a protective component 3, and the two sets of breathable components 2 are correspondingly installed on the upper surface and lower surface of the base layer 1. The protective component 3 is correspondingly installed on the upper surface of the ventilation component 2 .

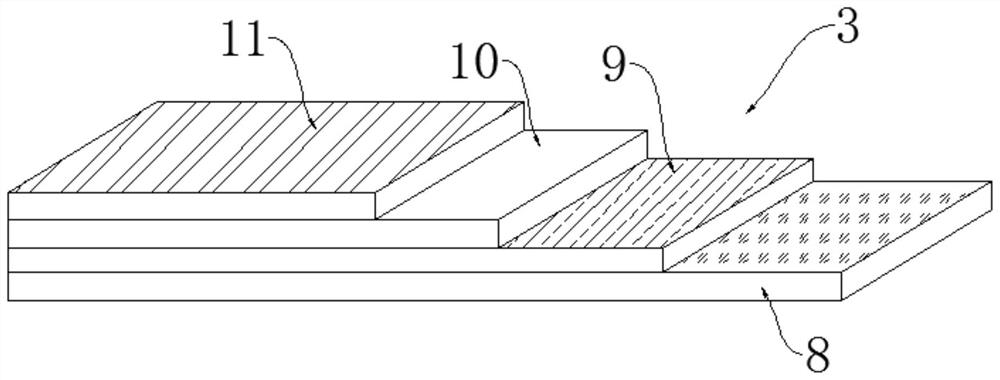

[0022] The air-permeable component 2 includes a silica gel layer 4, a No. 1 air-permeable layer 5 and a No. 2 air-permeable layer 6. The No. 1 air-permeable layer 5 is correspondingly hot-pressed on the upper surface of the silica gel layer 4 through the glue, and the No. 2 air-permeable layer 6 is passed through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com