Cleaning treatment device for metal pickup parts of stethoscopes

A technology for cleaning treatment and cleaning devices, which is applied in the field of stethoscopes, and can solve problems such as inability to resist, poor wiping effect, and inability to clean the sound pickup parts of the stethoscope, so as to achieve rapid flipping, improve work efficiency, and avoid the effect of being unable to flip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

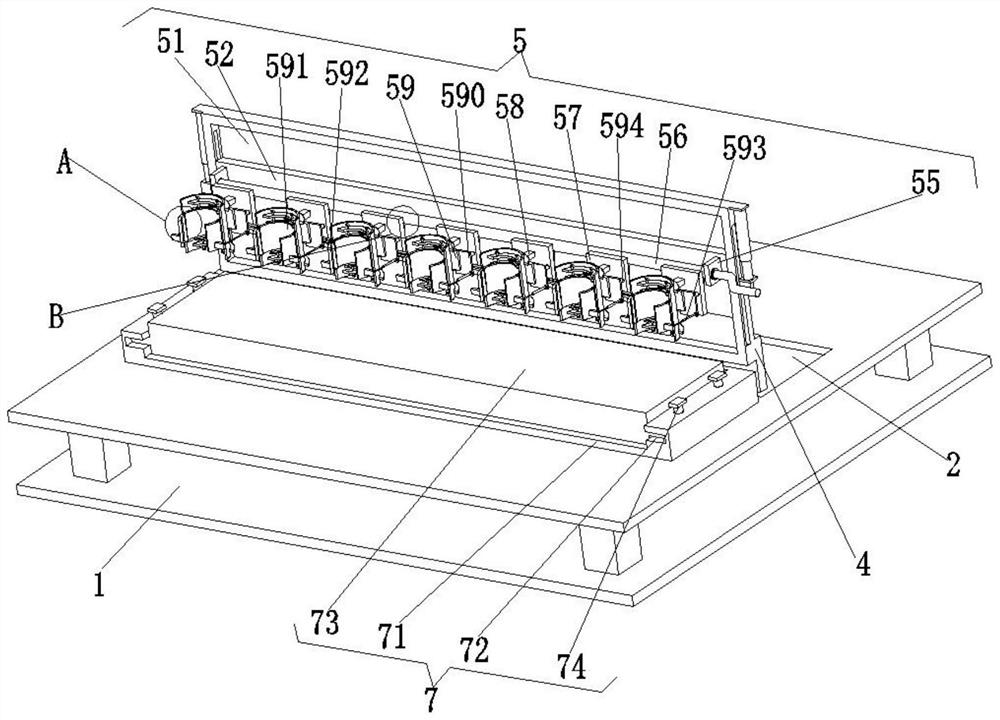

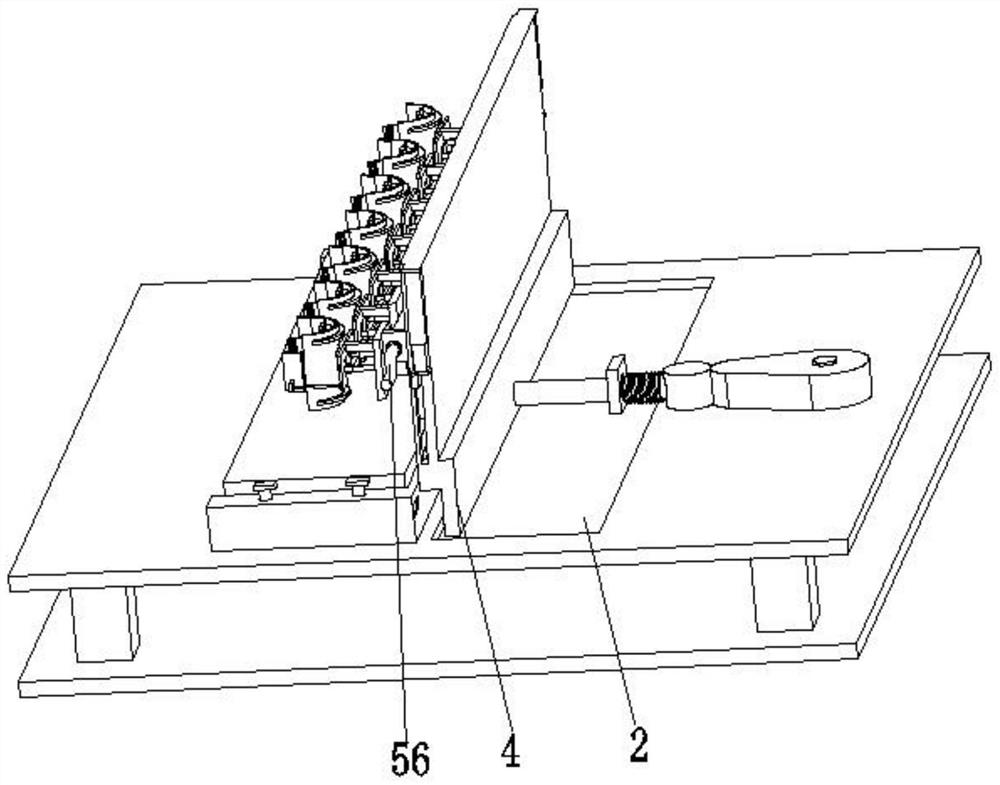

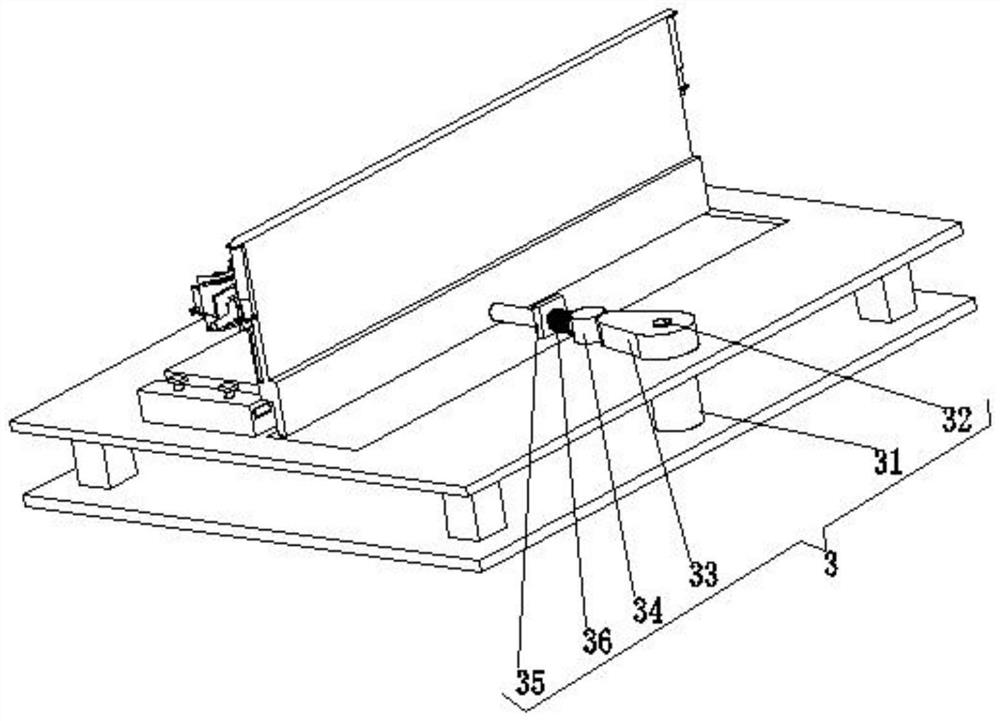

[0029] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 7 , to further elaborate the present invention.

[0030] A device for cleaning and processing metal sound-picking components of a stethoscope, comprising an I-shaped frame 1, a chute 2, a wiping device 3, a supporting substrate 4, a turning device 5, a fixing device 6, and a cleaning device 7, and the middle part of the upper surface of the I-shaped frame 1 is A chute 2 is provided, and a wiping device 3 is provided at the rear of the upper surface of the work frame 1. A support substrate 4 is slidably installed in the chute 2, and a turning device 5 is provided at the front of the support substrate 4. The front end of the turning device 5 is fixedly installed with a fixed Device 6, the lower part of the fixing device 6 is provided with a cleaning device 7 fixedly connected to the upper surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com