Combined ascending ladder

A combined and ladder-climbing technology, which is applied in the direction of ladders, buildings, building structures, etc., can solve the problems of troublesome loading and unloading process, inconvenient disassembly, single action form of climbing ladders, etc., and achieve the effect of reliable operation and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

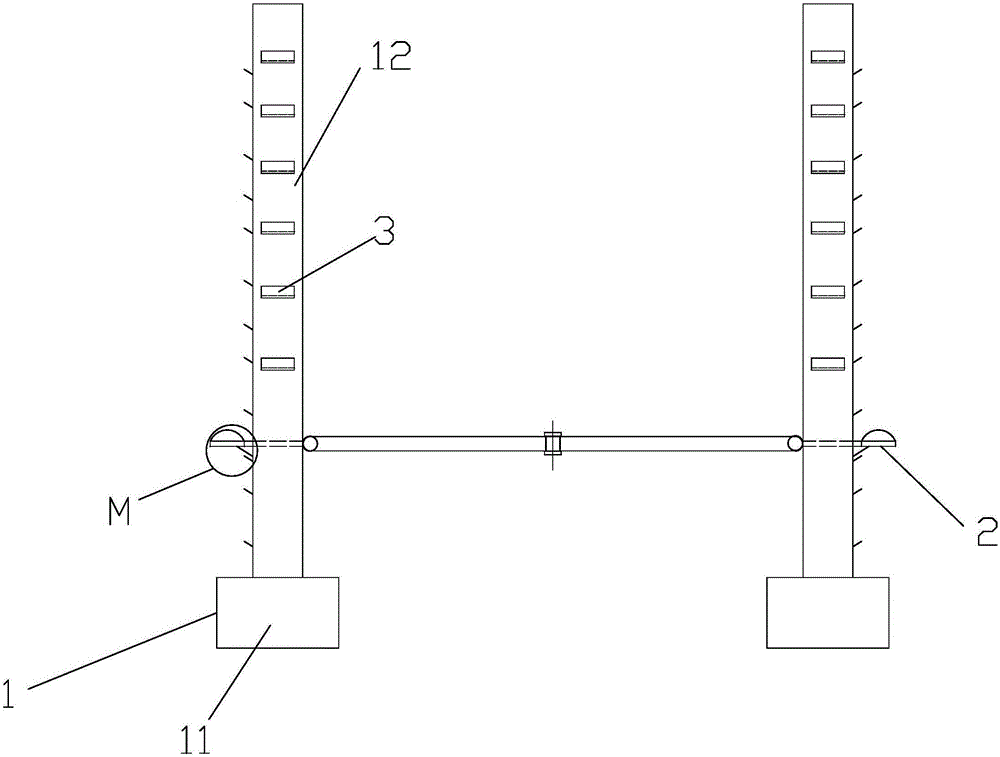

[0025] The invention is like Figure 1-6 As shown, a pair of rod assembly 1 and a pair of foot buckle assemblies 2 are included, and the foot buckle assemblies 2 are provided on the rod assembly 1 in a one-to-one correspondence;

[0026] The rod assembly 1 includes a base 11 and a ladder rod 12 provided on the base. The ladder rod is fixed on the base; the ladder rod 12 has a middle hole 120, and the inner side of the ladder rod is provided with a vertical chute 121 , The outer side is provided with a pair of parallel two sliding grooves 122 in the vertical direction, the first sliding groove is located between the pair of second sliding grooves, and the outer side of the ladder rod is evenly distributed with a number of baffles 123, the baffles are located at one Between the two chutes; during work, the first chute and the second chute are connected to the middle hole;

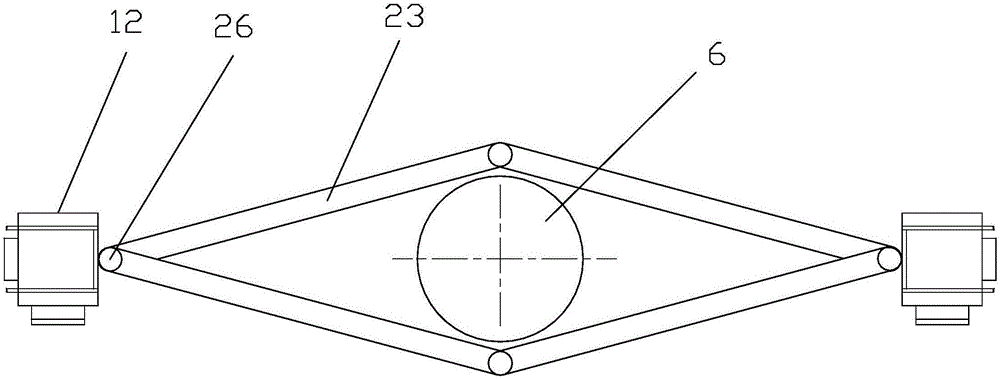

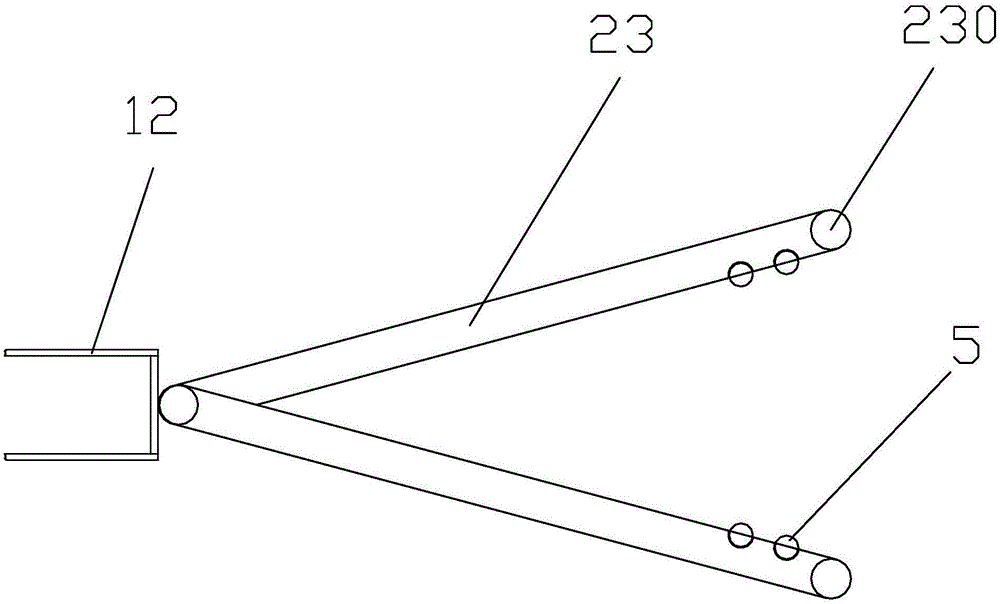

[0027] The foot buckle assembly 2 includes a buckle body 21, a sliding support 22, and a V-shaped frame 23. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com