High-speed testing machine for gear shaft bearing pack

A bearing group and testing machine technology, applied in the direction of mechanical bearing testing, etc., can solve the problems of inaccurate performance of service life, difficulty in evaluating the operating state of bearings, and inability to simulate helicopter working conditions well, so as to achieve real force and simulation effect accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

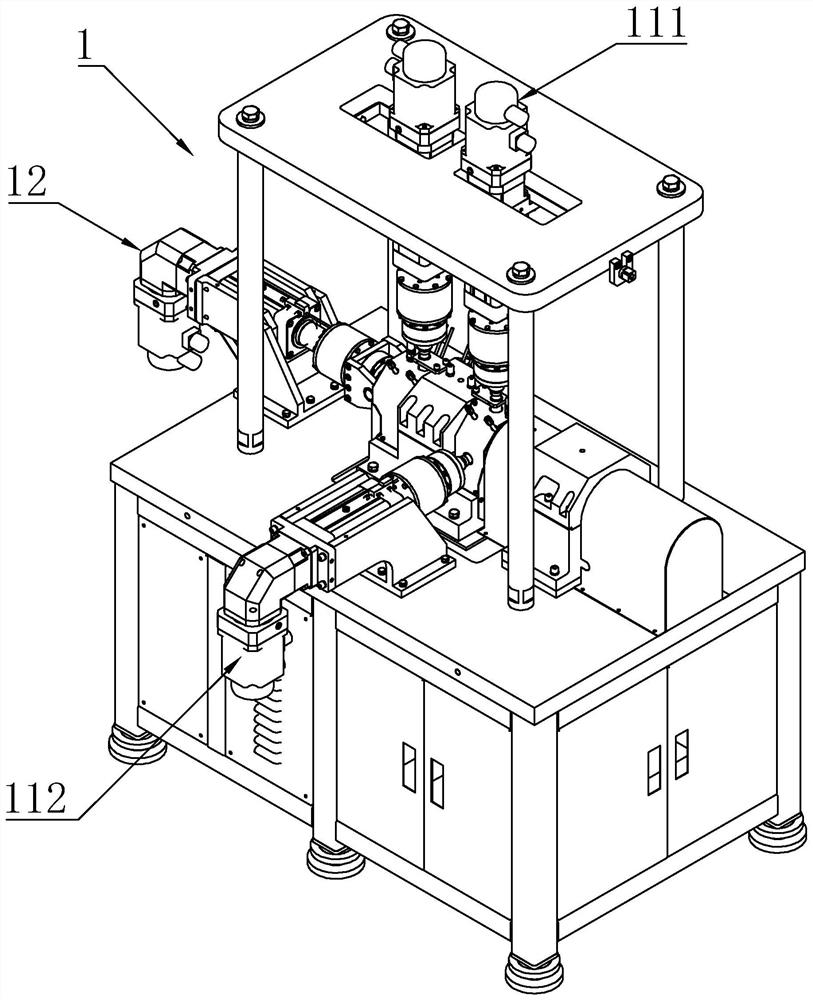

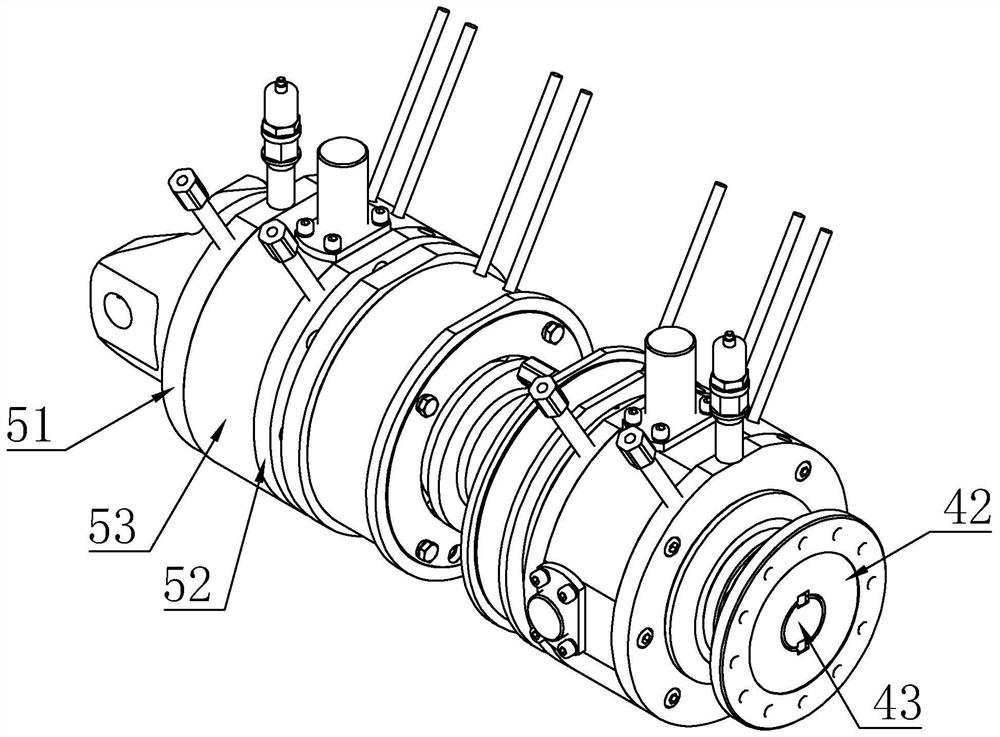

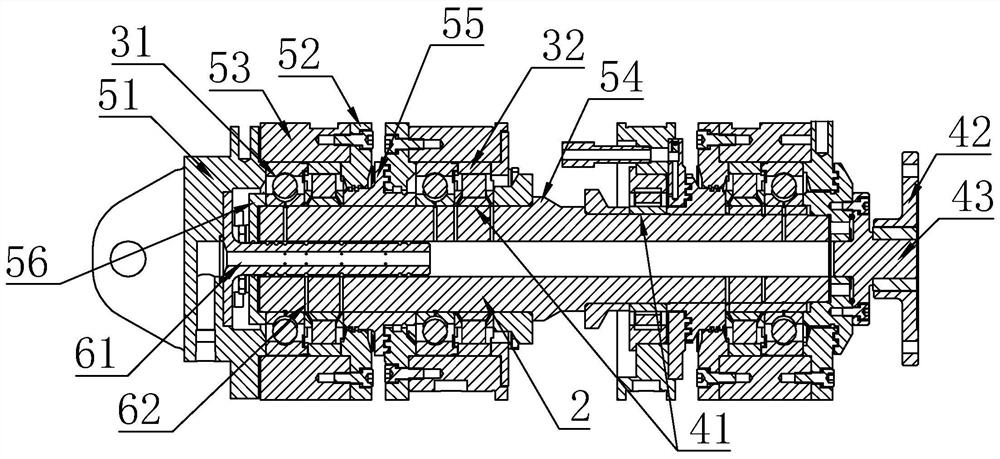

[0033] A high-speed testing machine for a gear shaft bearing group, the high-speed testing machine includes a bearing group and a force applying component 1 for applying force to the bearing group; the bearing group includes a test bearing 31 and a test bearing group that are coaxially connected to a rotating shaft 2 32. The inner ring of the accompanying test bearing 31 and the test bearing group 32 is sleeved on the rotating shaft 2 and is relatively fixed with the rotating shaft 2; Transfer to the transfer test bearing set 32.

[0034] In this design, the force application assembly 1 that can apply force in various directions to the test bearing 31 and the test bearing group 32 is adopted. At this time, it can simulate the working condition that the gear shaft of the helicopter is subjected to forces in various directions. At this time, it is easy to receive the force brought by different bevel gears. This scheme can simulate the force brought by each bevel gear, and then s...

Embodiment 2

[0040] Based on the solution of Embodiment 1, this embodiment sets the force application assembly 1 as a split type, which is specifically divided into a radial loading assembly and an axial loading assembly 12, so as to apply radial and axial forces to the test bearing 31 respectively. At this time, it is possible to simulate the radial and axial forces on the rotating shaft 2, and to show a more accurate force situation. Moreover, the requirement for the volume of the equipment is also small, and the integrated design will easily lead to an increase in volume, which is not conducive to optimization.

[0041] More specifically, in this embodiment, the radial loading assembly includes a radial vertical loading assembly 111 and a radial horizontal loading assembly 112 that can independently adjust the application force.

[0042] The radial loading component has forces applied in two directions. At this time, the forces in the two directions can be changed through independent ad...

Embodiment 3

[0044] A further modification is made based on the above-mentioned embodiment, the rotating shaft 2 has two sections with different diameters, which are respectively used to install the joints 41 of bearings with different inner diameters in the test bearing set 32 .

[0045] Two bearings of different sizes can be detected simultaneously through the joints 41 with different diameters at both ends, and the detection efficiency can be improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com