Lift strength tester

A strength test and elevator technology, which is applied in transportation, packaging, elevators, etc., can solve the problems of high test cost, inconsistent force on the wire ropes on both sides of the traction wheel, difficult installation and maintenance, etc., and achieve simple operation and maintenance. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

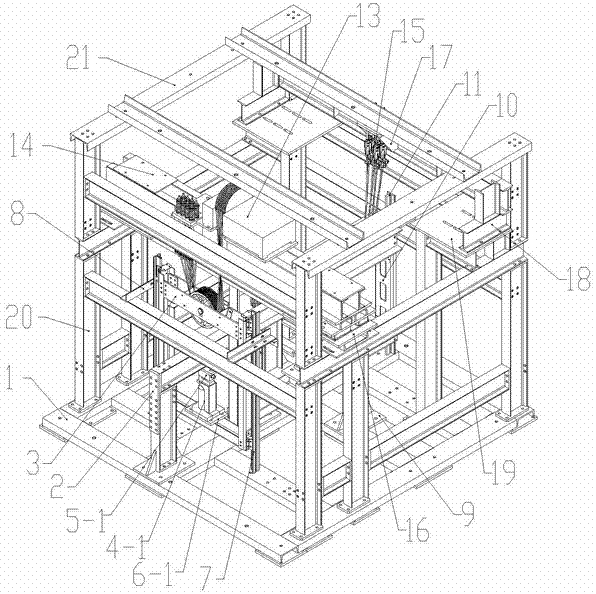

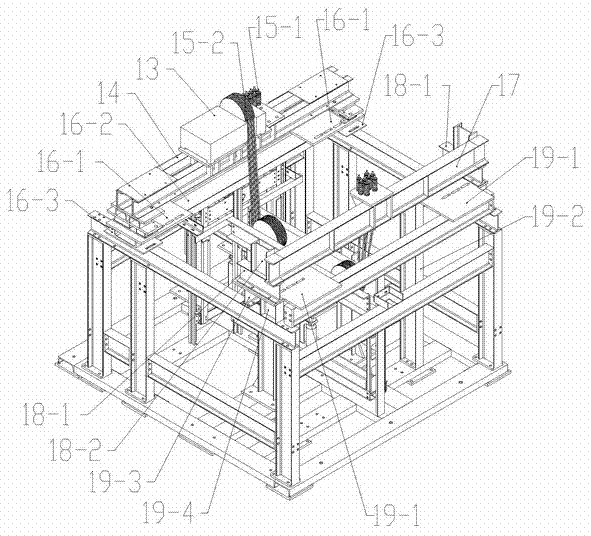

[0041] Such as figure 1 , Figure 4 and Figure 5 As shown, the elevator strength test device of the present invention includes: a base 1, a counterweight gantry 2 located on the left side of the base 1, and a car frame gantry 9 located at the middle of the base 1. The lower end of the heavy gantry frame 2 is fixed to the base 1 by bolts or welding, and the car frame gantry 9 is fixed to the base 1 by bolts or welding.

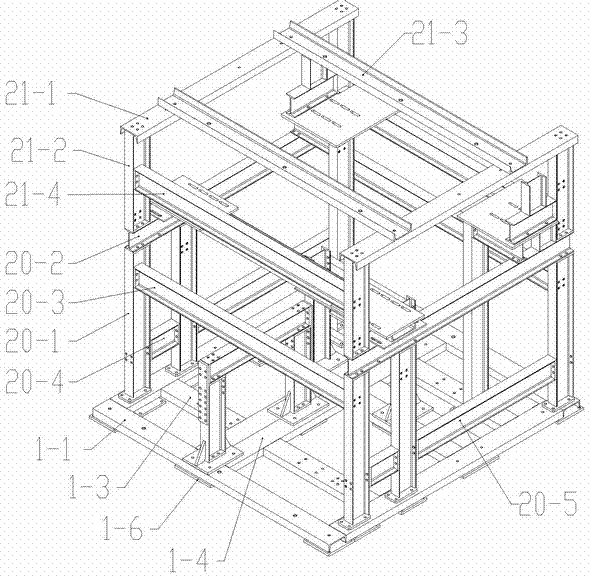

[0042] Such as image 3 As shown, the base 1 is welded into a horizontal four-frame by four base channel steel 1-1 with the notch facing downwards, and the interior of the four-frame is composed of at least one (preferably two) installation channel steel 1-1 with the notch facing downward. 4. Weld at least six support channel steels 1-3 to form a base support structure flush with the four frames; there are at least eight backing plates 1-6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com