Method for measuring breakage rate of propping agent

A measurement method and proppant technology, which is applied in the direction of measuring devices, earthwork drilling, mining fluids, etc., can solve the problem of not considering the fracture, not considering the difference in fracture rate between dry and wet samples of proppant, and not truly reflecting the fracture rate of proppant and other problems, to achieve the effect of real broken rate results and better broken rate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

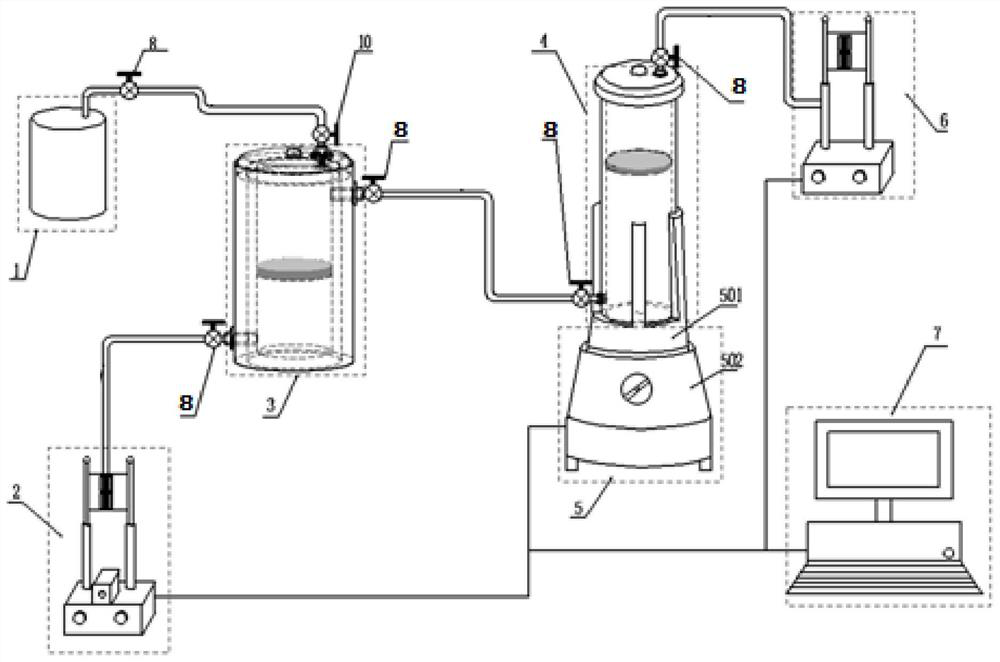

[0054] Embodiment one: if Figure 2 to Figure 4 As shown, a device for measuring proppant fragmentation rate includes: delivery unit 4, stirring unit 5, first pumping unit 6, pressure-bearing unit 3, second pumping unit 2, data recording control unit 7, screening unit.

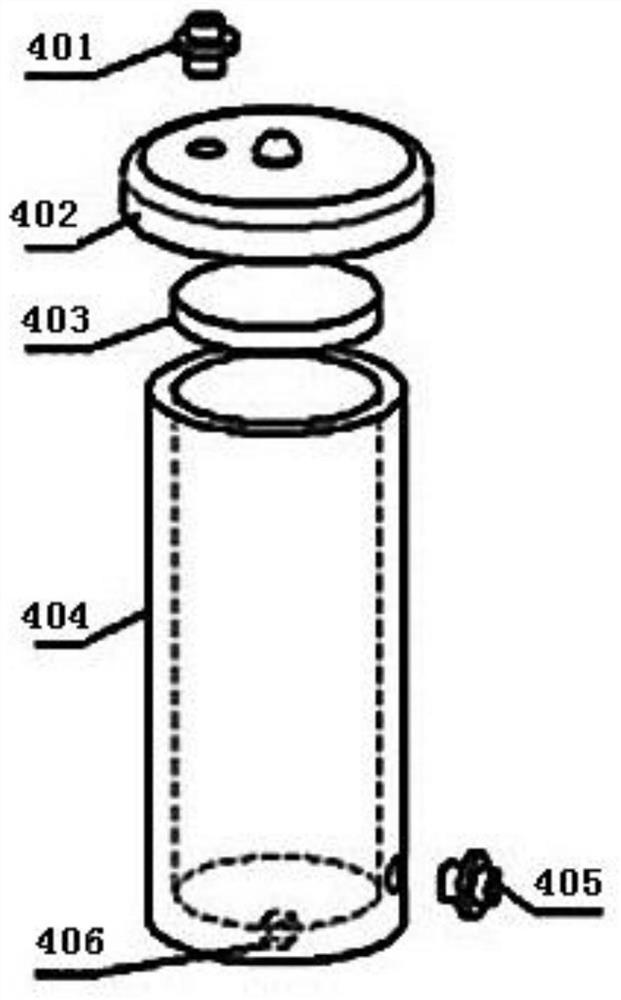

[0055] The delivery unit 4 is composed of a first cylinder 404 , a first piston 403 and a first top cover 402 . The first cylinder 404 can bear pressure for simulating a wellbore. There is a screw on the upper part of the first cylinder 404, and the first cylinder 404 is combined with the first top cover 402 through the screw; the lower side has a hole for simulating bottom hole injection. hole (during fracturing construction, the proppant is perforated from the bottom of the well into the formation), the hole is not polished, and the first pipe joint 401 is set at the opening, and the first pipe joint 401 is connected to the first pumping unit 6 through a pipeline. And a valve 8 is installed at the opening;...

Embodiment 2

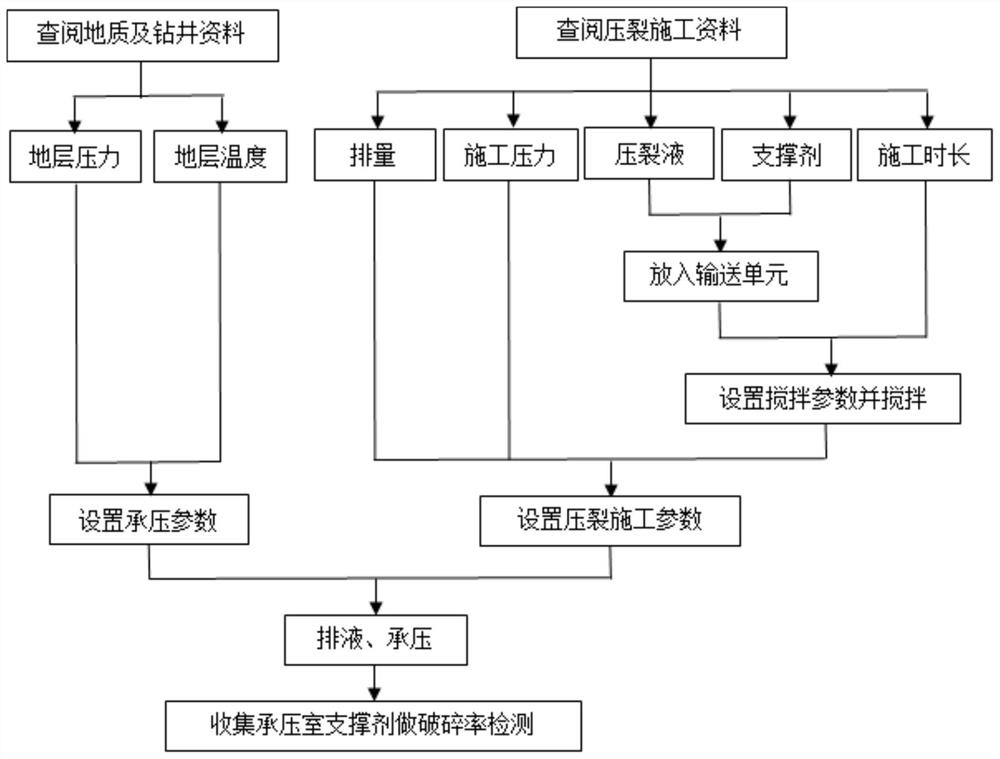

[0062] Embodiment two: if figure 1As shown, this embodiment is further optimized on the basis of Example 1, a method for measuring a proppant fragmentation rate measuring device, comprising the following steps:

[0063] Step 1: Prepare the mixed solution of fracturing fluid and proppant, and put the mixed solution into the delivery unit 4;

[0064] Step 2: stirring the mixed solution in the delivery unit 4;

[0065] Step 3: pump the stirred mixed solution into the pressure-bearing unit 3;

[0066] Step 4: Pressurize the mixed liquid in the pressure-bearing unit 3 for a certain period of time;

[0067] Step 5: After bearing pressure for a certain period of time, the mixed fluid in the pressure bearing unit 3 is reversely drained to discharge the liquid;

[0068] Step 6: After draining, pressurize the proppant in the pressure-bearing unit 3 for a certain period of time;

[0069] Step 7: Collect the proppant after the second pressurization, and calculate the fracture rate.

...

Embodiment 3

[0085] Embodiment three: this embodiment carries out experiment on the basis of embodiment two:

[0086] This embodiment provides a calculation formula for converting on-site construction displacement into indoor experimental flow, as described in the following formula:

[0087]

[0088] In the formula: Q 施工 —— On-site construction displacement, m 3 / min;

[0089] V 总 ——The total amount of on-site construction medium, m 3 ;

[0090] t 总 ——total construction time on site, min;

[0091]

[0092] In the formula: Q 实验 ——Indoor experimental flow rate, mL / min;

[0093] V' 总 ——The total amount of indoor experimental medium, mL;

[0094] t' 总 ——Total time of indoor experiment, min;

[0095] Q=v×s------------------------------------------(3)

[0096] In the formula: Q——the flow rate in a specific time, m 3 / s;

[0097] v——flow velocity in the pipeline, m / s;

[0098] s——the cross-sectional area of the pipe, m 2 ;

[0099] The experimental simulation parameter s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com