Device for preventing wire from being wound and knotted and using method

A technology of wire rods and guide rods, applied in the field of wire rod pay-off devices, can solve the problems of easy overload shutdown of motors, affecting production efficiency, reducing production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

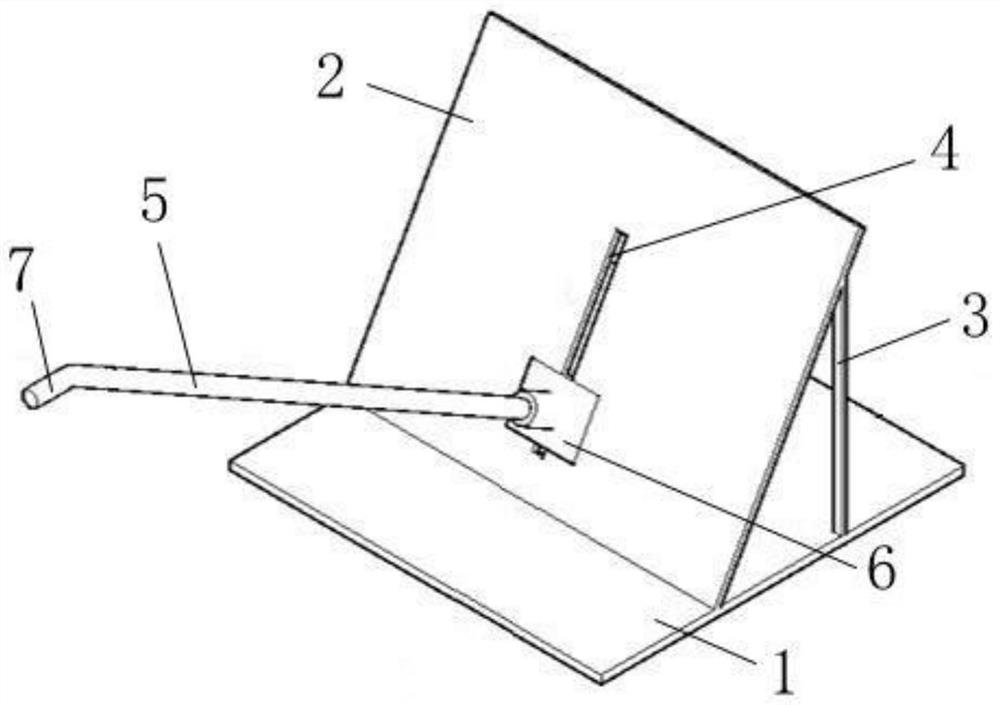

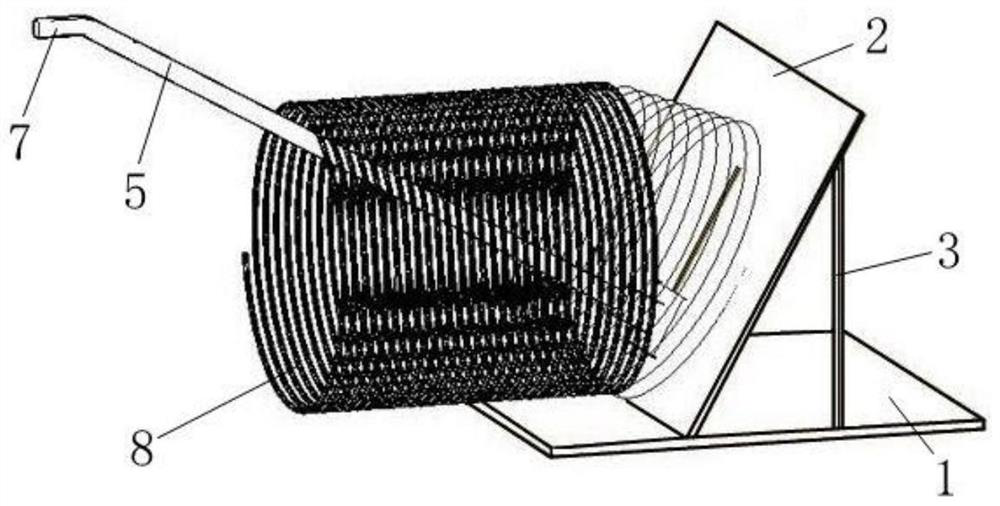

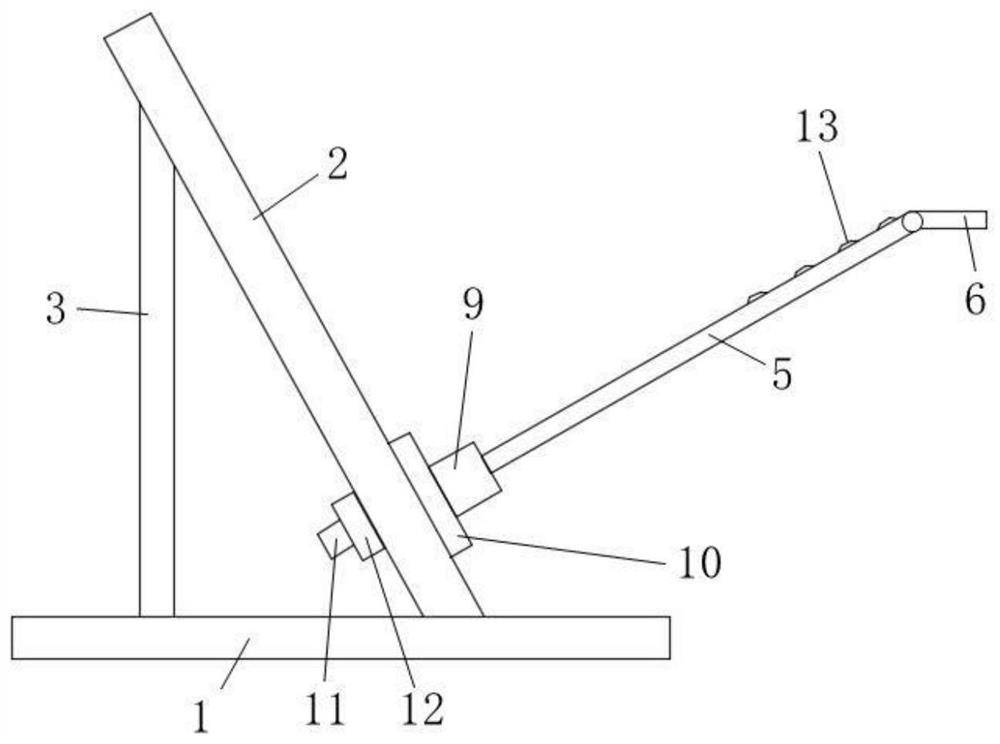

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0026] It is worth noting that the orientation words such as "up" and "down" involved in this article are all determined relative to the perspective of the drawings, and are only for the convenience of description, and cannot be understood as limitations on the technical solution.

[0027] The wire rod 8 on the conventional pay-off device needs to be rotated because the wire rod 8 will be released naturally during the rotation process. When the wire device is set horizontally, that is, the wire 8 is placed horizontally, and the wire 8 will wind more and more tightly around the shaft passing through the wire 8 in the pay-off device, and the pay-off cannot be performed normally. When the pay-off device is vertically set, the wire 8 is vertical. placed, the overlapping wires 8 will be pulled out at the same time, and the phenomenon of winding and knottin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com