Savoury composition

A composition, savory technology, applied in the field of savory food, can solve the problems of unsightly fat staining, soft properties of cooking aids, easy to sag and flatten, unacceptable fat content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A method for preparing a savory food for preparing soup or broth is provided, comprising the steps of:

[0034] i) preparing a savory composition by mixing edible salt, vegetable matter and a particulate binder, ii) adding water to said savory composition while mixing,

[0035] iii) filling a mold with said savory composition and placing an elongated member in said savory concentrate such that said elongated member extends from said savory composition,

[0036] iv) removing said savory composition from said mold together with said elongated member to provide a savory food consisting of a savory composition having an elongated member extending therefrom,

[0037] v) drying the savory food at a temperature of 20 to 50° C. for 3 minutes to 24 hours, until the water content is preferably lower than 10 wt.% of the weight of the savory composition.

[0038] Preferably, the savory composition comprises:

[0039] a) 1 to 15 wt.% of edible salt selected from sodium chloride, p...

Embodiment 1

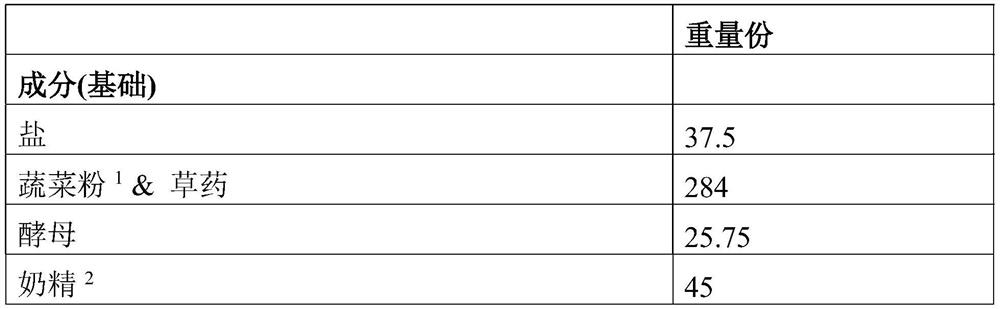

[0141] According to the recipe in Table 1, the savory and fresh composition was prepared. A base mixture of salt, tomato powder, vegetable powder, yeast, creamer, fat powder, herbs and potato starch is first mixed together and added to the areomyl, Maltodextrin or dextrose (use according to Table 1). The mixture was mixed at top speed for 10 seconds, then water was slowly added over 10 seconds. The resulting mixture was mixed for 60 seconds.

[0142] Table 1

[0143]

[0144]

[0145] 1 <5mm particle size

[0146] 2 75% fat

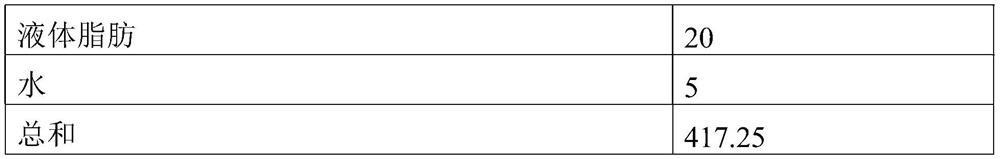

[0147] In summary, 400 parts of the base mix of Table 1 were mixed with 80 parts of expanded gelatinized potato starch (composition 1), maltodextrin (composition 2) or dextrose (composition 3) and 50 parts of water as shown in Table 2 :

[0148] Table 2

[0149] Ingredients / parts by weight 1 2 3 base mix 400 400 400 Aeromyl (Puffed and Gelatinized Potato Starch) 80 0 0 maltodextrin 0 80 0 glucose 0 ...

Embodiment 2

[0159] The savory food was prepared using the savory composition 4. Fill the mold with savory composition 4. A wooden stick is placed in the composition so that the stick extends from the mold. The molds were covered with complementary molds and pressed together with a force of 1 kg. After 30 seconds the mold is opened and the savory food is taken out of the mold.

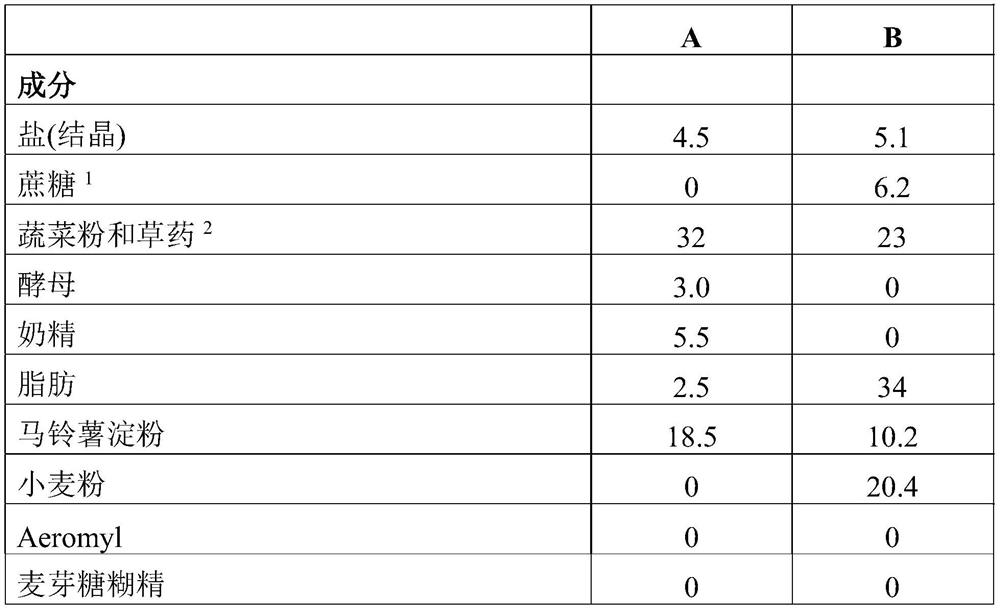

[0160] table 5

[0161]

[0162]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com