Base module and functional module for an electrical enclosure system, and electrical enclosure system

A technology of basic modules and functional modules, applied in the field of switchgear systems, can solve the problems of not being able to replace components, not complying with production shutdowns, addressing, etc., and achieve the effect of preventing production shutdowns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

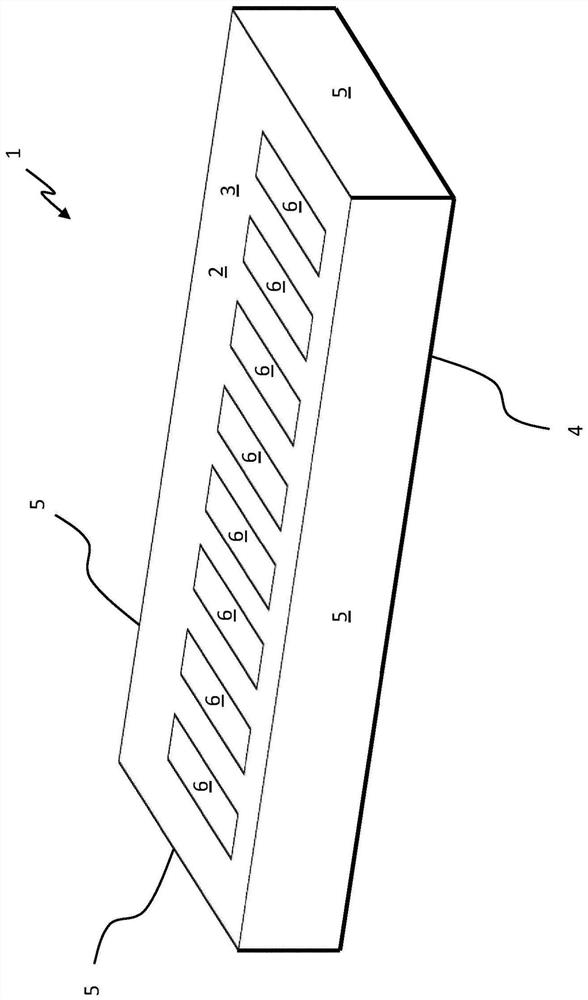

[0036] figure 1 A first basic module 1 for a switchgear system according to a first embodiment is schematically shown in a perspective view.

[0037] The first basic module 1 has a housing 2 . The housing 2 can be produced completely or at least partially from a metallic material, for example from aluminum. The housing 2 has an upper side 3 , a lower side 4 opposite the upper side 3 and four side walls 5 . The upper side 3 of the housing 2 has a plurality of holes 6 . Exemplarily, figure 1 The upper side 3 of the center has eight holes 6 .

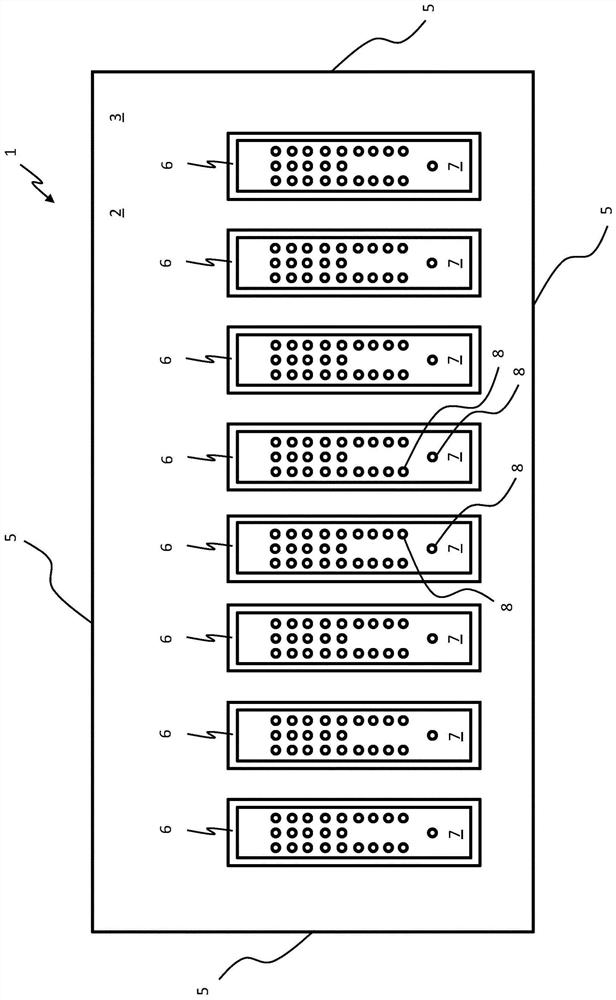

[0038] figure 2 A top view schematically shows the figure 1 The first basic module 1.

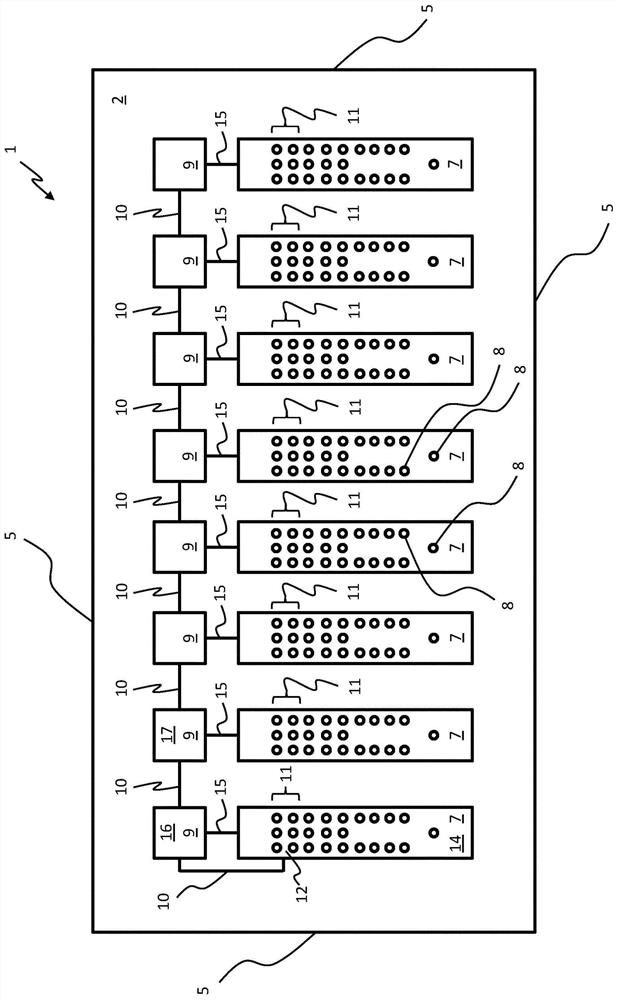

[0039] The first basic module 1 has a plurality of connection elements 7 . These connecting elements 7 are arranged in the housing 2 . Each connecting element 7 is respectively arranged in the region of the bore 6 . These connection elements 7 have contacts 8 . Exemplarily, each connecting element 7 has twenty-four contacts 8 . However, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com