Linear roller bearing provided with a sensor for determining displacement resistance

A sensor, linear technology, applied in the direction of linear motion bearing, bearing, bearing assembly, etc., can solve the problem of not monitoring the formation of pitting corrosion or undesired entry of dirt, and achieve the effect of preventing production downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

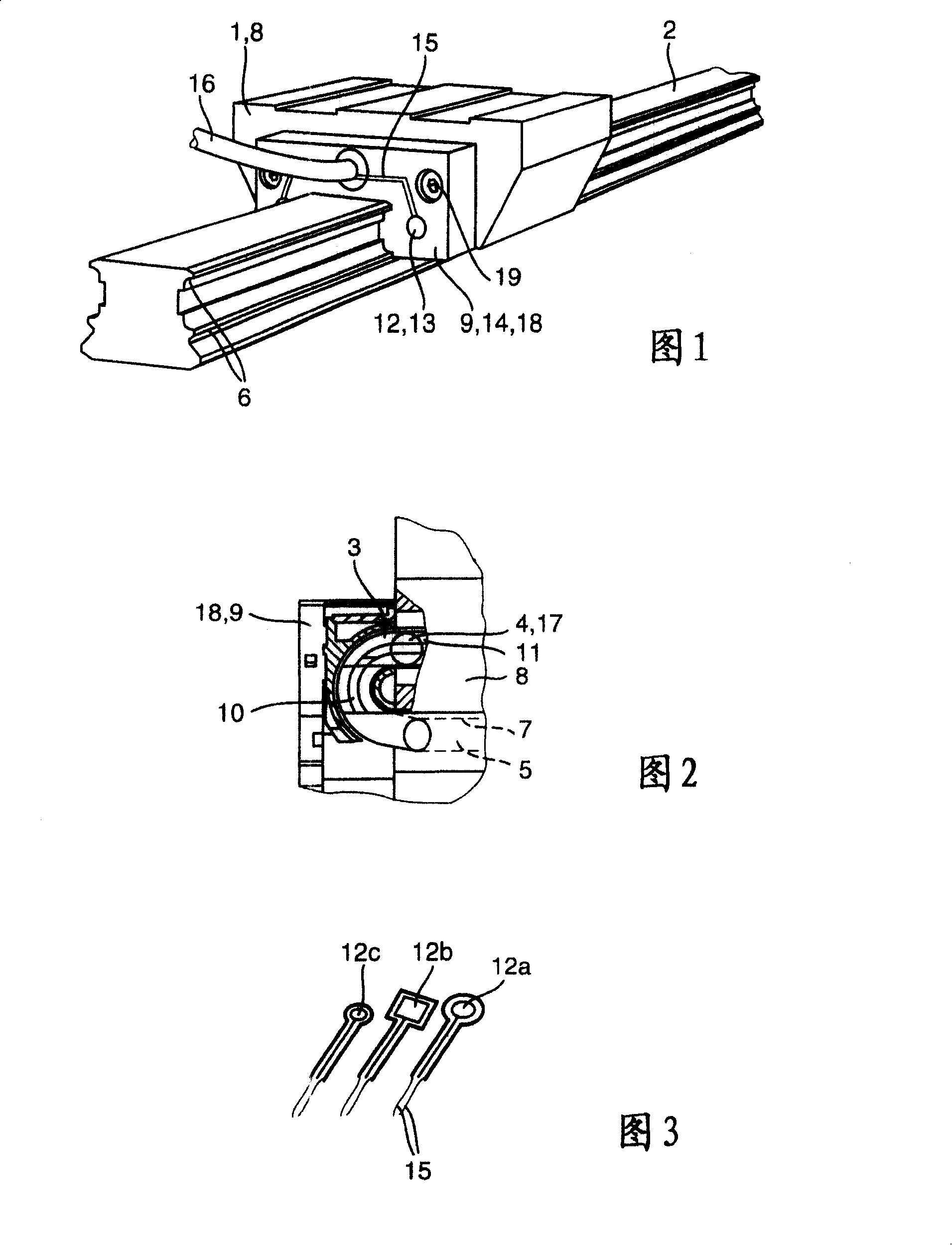

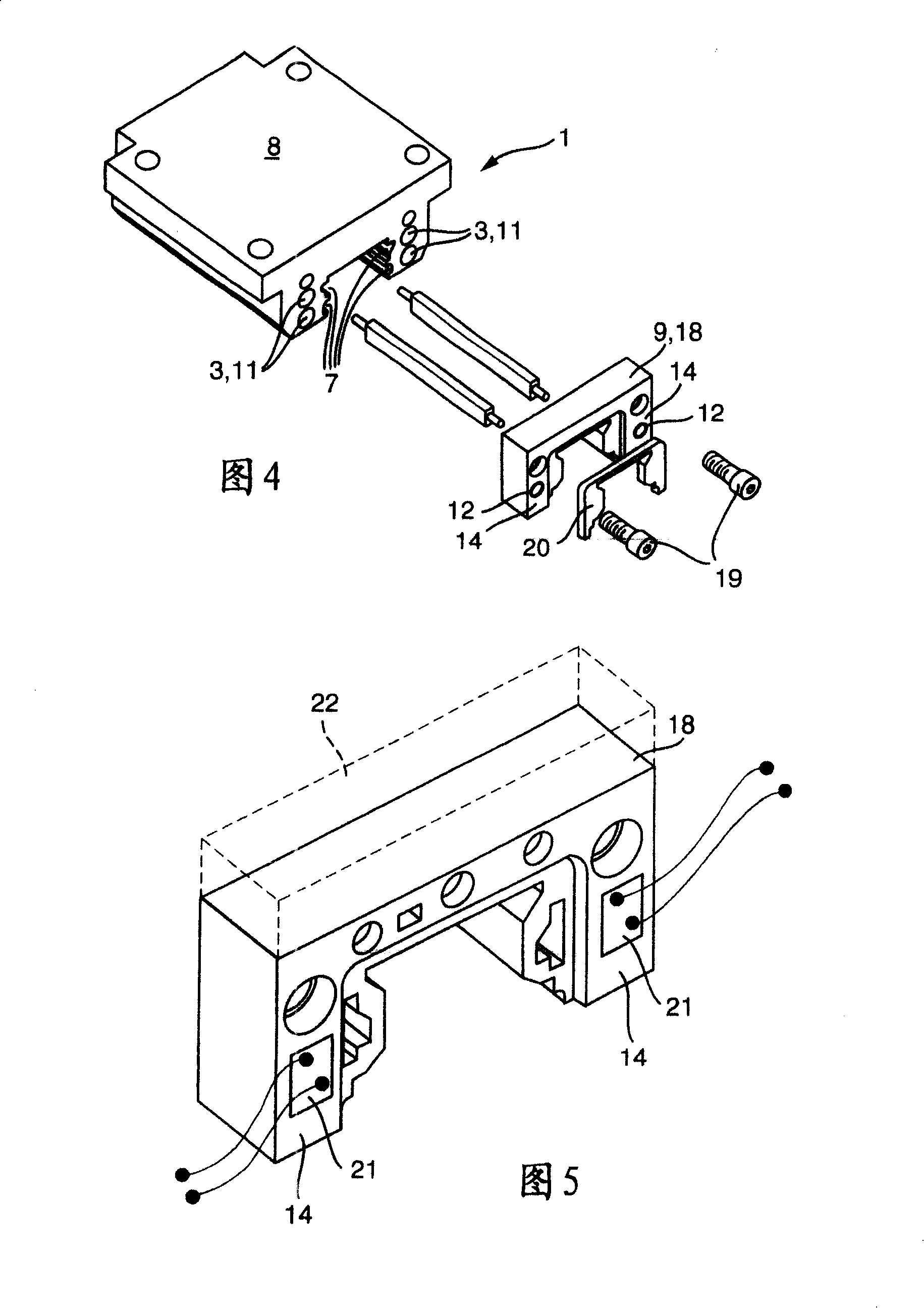

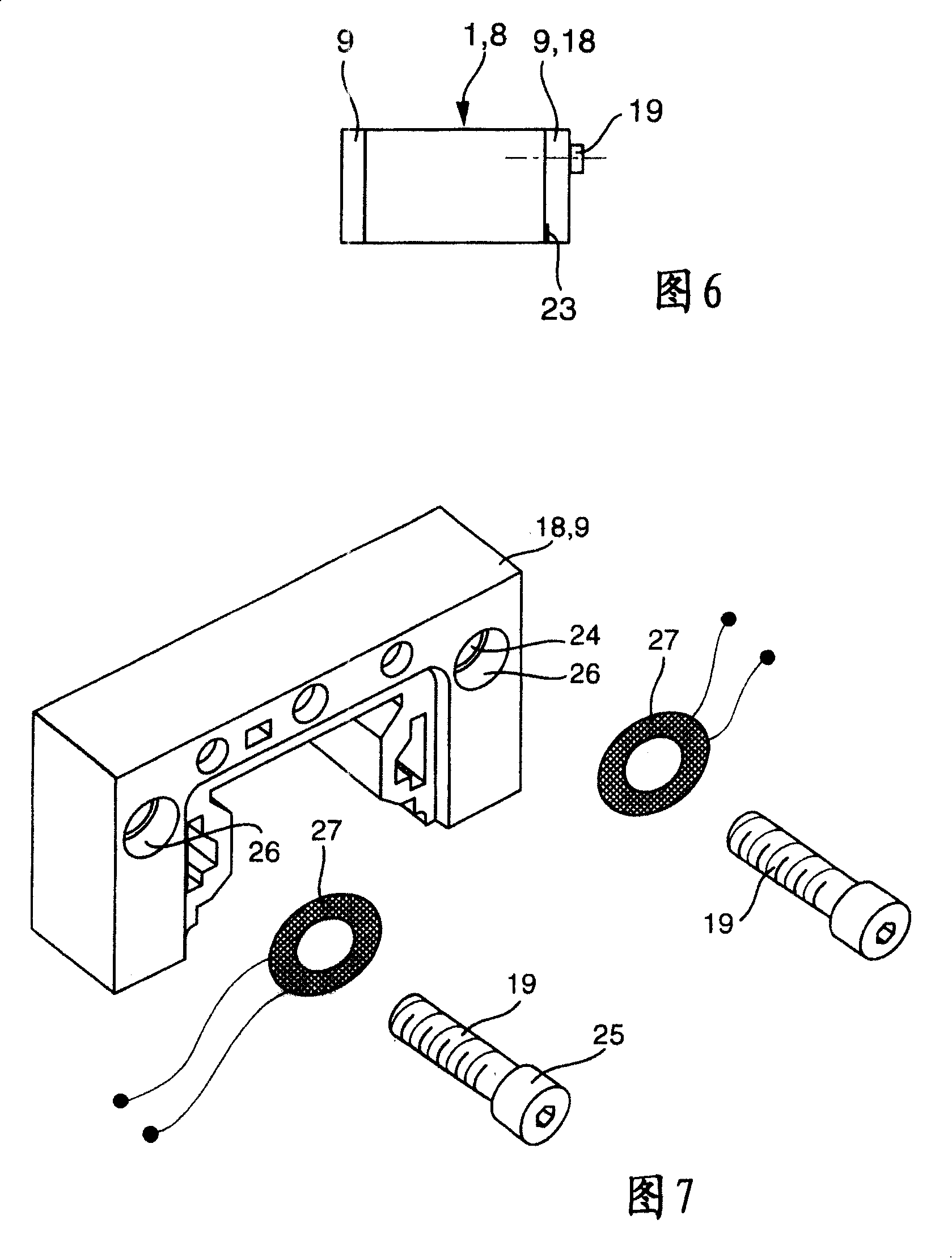

[0029] The linear rolling bearing shown in FIGS. 1-4 has a carriage 1 which is mounted rolling on a guide rail 2 . The carriage 1 comprises two continuous rolling body channels 3 for rolling bodies 4 on both longitudinal sides of the guide rail 2 , one of which is shown in FIG. 2 . Each rolling body channel 3 includes a bearing channel 5 for a loaded rolling body 4 . In the bearing channel 5 the rolling bodies 4 roll on raceways 6 , 7 , of which one raceway 6 is formed on the guide rail 2 and the other raceway 7 is formed on the bearing body 8 of the carriage 1 .

[0030] An end section 9 is provided on both end faces of the carrier body 8 , in which a deflection channel 10 is formed. The rolling body channel 3 also includes a return channel 11 , which is formed on the bearing body 8 . The two deflection channels 10 connect the bearing channel 5 via a return channel 11 to the continuous rolling body channel 3 in which the rolling bodies 4 circulate continuously.

[0031] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com