Laser emitting device for three-dimensional positioning

A technology of laser emission and three-dimensional positioning, which is applied in the direction of using optical devices, active optical measuring devices, measuring devices, etc., which can solve the problems of limiting positioning accuracy and the inability of laser rotors to handle small high-frequency oscillations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

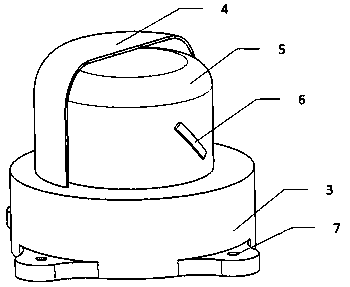

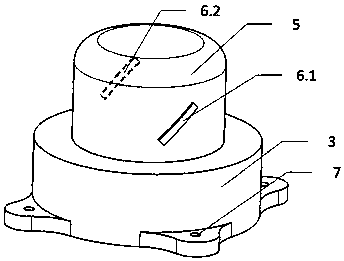

[0014] A laser emitting device for three-dimensional positioning, including a laser emitting rotating device, a control circuit board, a mounting base, and a transparent casing; the laser emitting rotating device includes a vertically installed, stable high-speed rotating motor and two laser emitting part. The two laser emitting parts are installed in the central part of the motor in the vertical direction, arranged on the symmetrical sides of the motor, forming a mirror image. The rotation of the motor can drive the two laser emitting parts to rotate synchronously.

[0015] The control circuit board is installed inside the mounting base, which saves equipment space.

[0016] There are four mounting holes on the mounting base for fixing the device body.

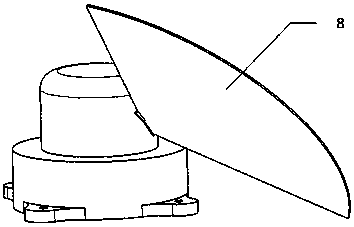

[0017] The laser emitting part will release the fan-shaped laser surface to the space, and the angle of the laser surface is in a degree angle relationship with the vertical direction of the motor, wherein the laser emittin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com