Grinding wheel machine capable of collecting waste materials

A grinding wheel and turbine technology, which is applied in grinding/polishing equipment, grinding/polishing safety devices, metal processing equipment, etc., can solve problems such as easy accumulation of dust, and achieve the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

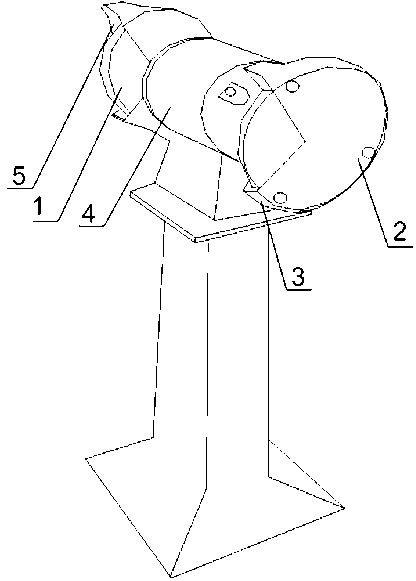

[0018] Such as figure 1 As shown, this embodiment includes a motor 4 and a grinding wheel 1, and also includes a grinding wheel cover arranged on the motor 4, and the grinding wheel cover includes an arc groove 3 and a fan-shaped disc cover 2, and the fan-shaped disc cover 2 and the arc-shaped groove 3 are connected by bolts, the grinding wheel 1 is placed in the arc-shaped groove 3, and the bottom of the arc-shaped groove 3 is also provided with an opening. The traditional grinding wheel machine is only provided with a half-circle cover, and construction personnel often cause fingers to be scratched by the grinding wheel 1 due to carelessness. The present invention is provided with an arc groove 3 and a fan-shaped disc cover 2, and the fan-shaped disc cover 2 is bolted to the arc-shaped groove 3 and can be disassembled to facilitate the cleaning, disassembly and installation of the grinding wheel 1; the arc-shaped groove 3 connects the grinding wheel 1 more It is partially p...

Embodiment 2

[0020] Such as figure 1 As shown, on the basis of Embodiment 1, the present embodiment is also provided with a duckbill opening 5 on the arc groove 3, and when the grinding wheel 1 is in contact with the workpiece, a large amount of debris generated at the notch of the arc groove 3 Splash, the setting of the duckbill opening 5 on the arc-shaped groove 3 makes the splashed debris bounce back into the groove, and finally be collected under the action of the waste collection device, which improves the processing efficiency.

Embodiment 3

[0022] Such as figure 1 As shown, this embodiment is based on Embodiment 1, and the diameter of the hole is greater than the thickness of the grinding wheel 1 . Due to the fast rotation of the grinding wheel 1, the debris and dust produced will accumulate quickly. If the diameter of the opening is too small, the collection rate of the waste collection equipment will also be reduced, and the speed of waste leakage cannot catch up with the speed of dust generation. It will cause blockage in the arc-shaped groove 3 and affect the processing efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com