Spring grinding machine

A spring grinding machine and grinding technology, which is applied in the field of spring processing, can solve the problems of low efficiency of spring end replacement, and achieve the effect of not easy displacement, stable installation, and high efficiency of end replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

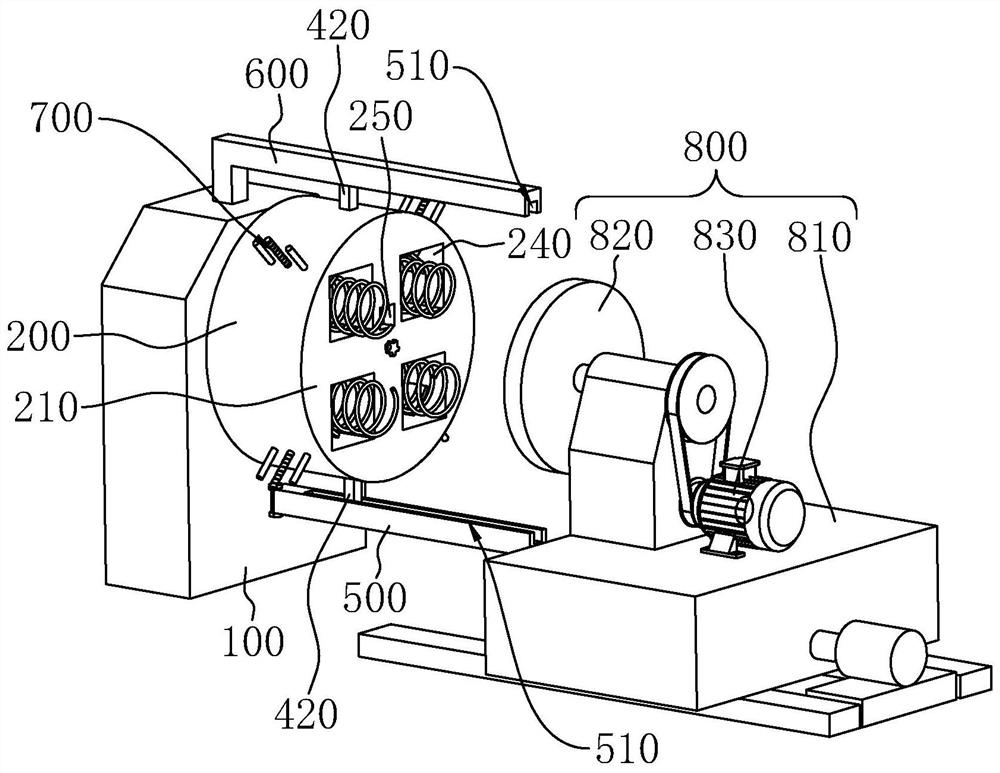

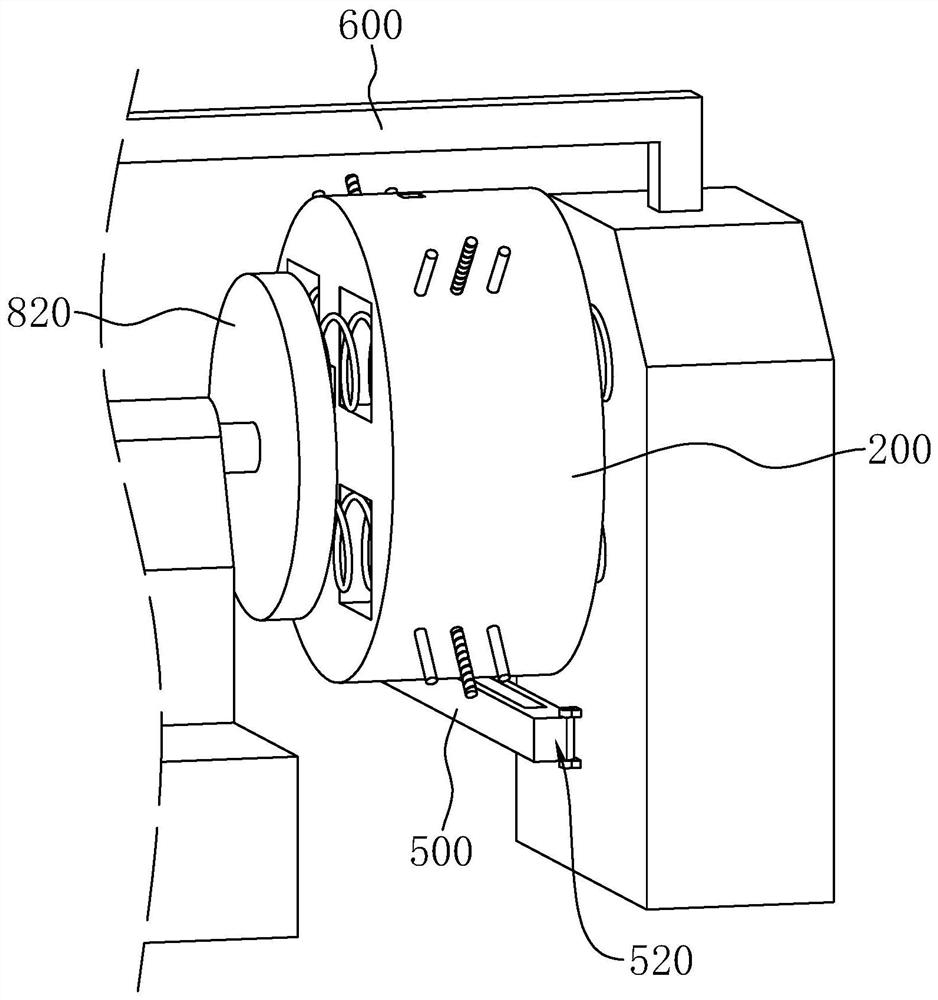

[0041] Embodiment 1: The embodiment of this application discloses a spring grinding machine, refer to figure 1 and figure 2 , including a grinding mechanism 800 and a clamping mechanism, the grinding mechanism 800 is located on one side of the clamping mechanism, and the grinding mechanism 800 is slidably installed in a direction approaching / far away from the clamping mechanism through a cylinder and a slide rail.

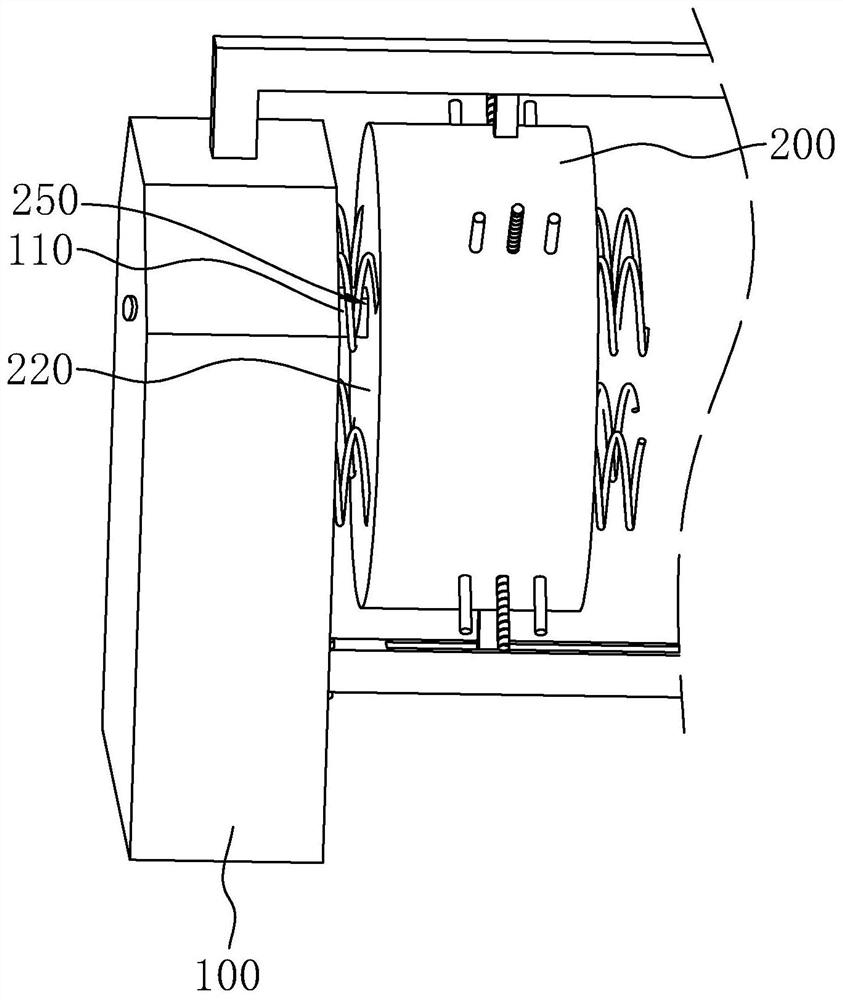

[0042] The clamping mechanism includes a frame 100 and a mounting frame 200. The mounting frame 200 is a cylinder, and the eccentric parts of both ends of the mounting frame 200 are provided with a connecting groove 250 with a square cross section. The frame 100 is fixedly connected with a connecting block 110, and the connecting block The cross-section of 110 fits with the connection groove 250 , and the connection block 110 is embedded in the connection groove 250 , so that the installation frame 200 is detachably connected to the frame 100 in the circumferentia...

Embodiment 2

[0064] Embodiment 2: refer to Figure 7 , the difference from Embodiment 1 is that the installation frame 200 is rotatably connected with the installation plate 900, the rotation axis of the installation plate 900 is set horizontally, the second motor 120 is installed on the frame 100, and the second motor 120 is driven and installed by a belt. The plate 900 is connected and drives the mounting plate 900 to rotate, and the rotating direction of the mounting frame 200 is opposite to that of the grinding disc 820 . The second motor 120 drives the mounting frame 200 to rotate, which can improve the grinding efficiency.

[0065] A side of the mounting plate 900 away from the second motor 120 is fixedly connected with a plurality of inserting blocks 910 , and two ends of the mounting frame 200 are provided with a plurality of slots 920 , the cross sections of the inserting blocks 910 match the cross sections of the slots 920 . The middle part of the insert block 910 is fixedly con...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap