Wear indication device for a flow control valve

A technology of flow control and equipment, which is applied in the direction of sliding valves, mechanical equipment, devices for absorbing fluid energy of valves, etc., and can solve problems such as damage to the internal parts of the valve, strong, bursting of the steam chamber, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

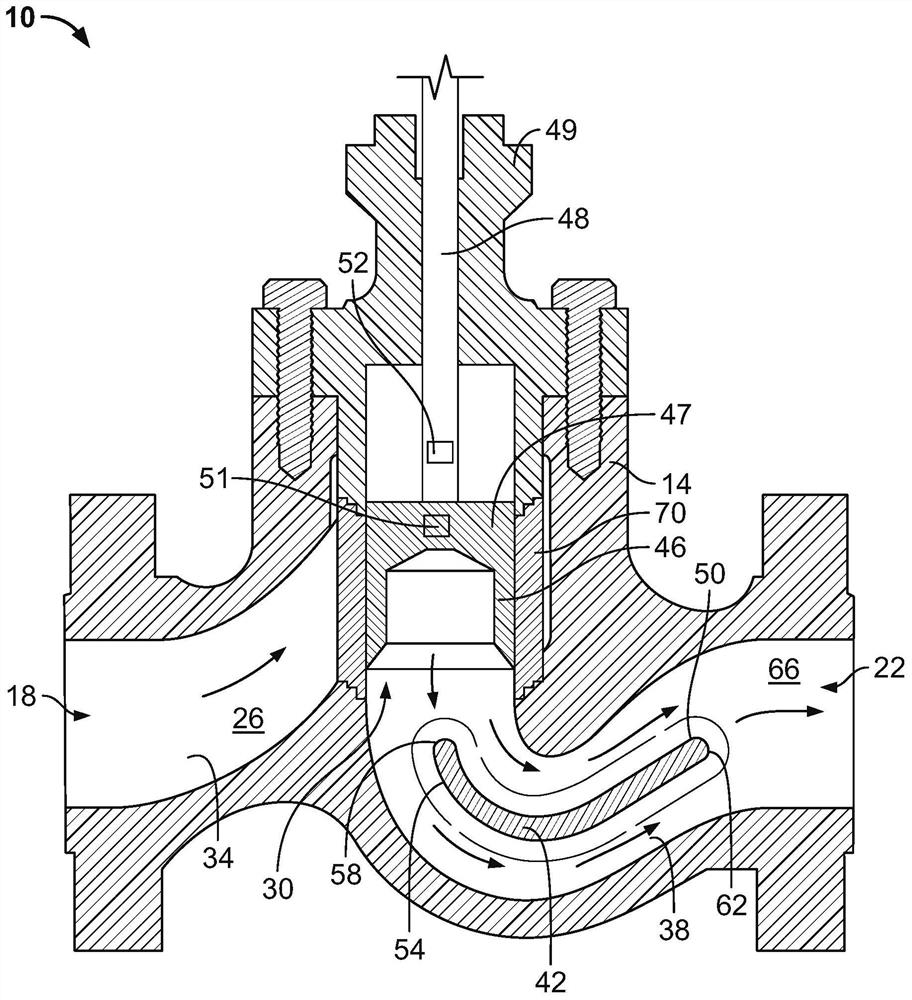

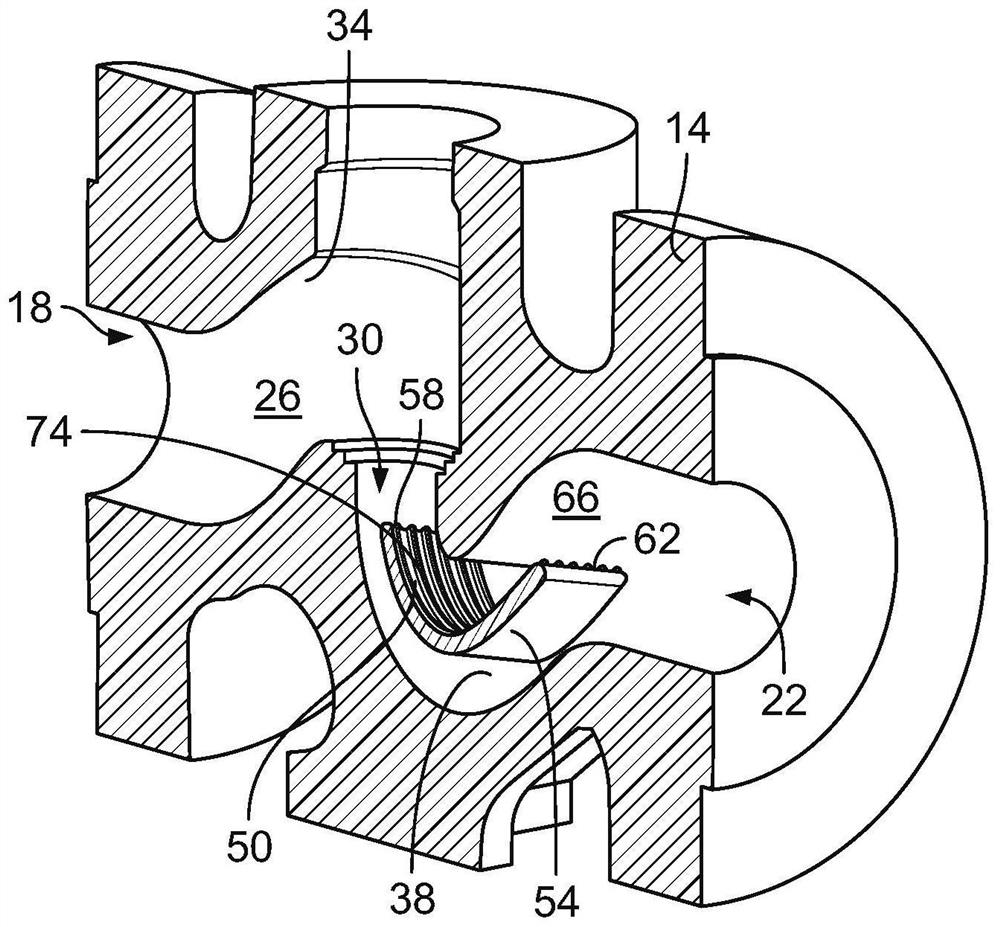

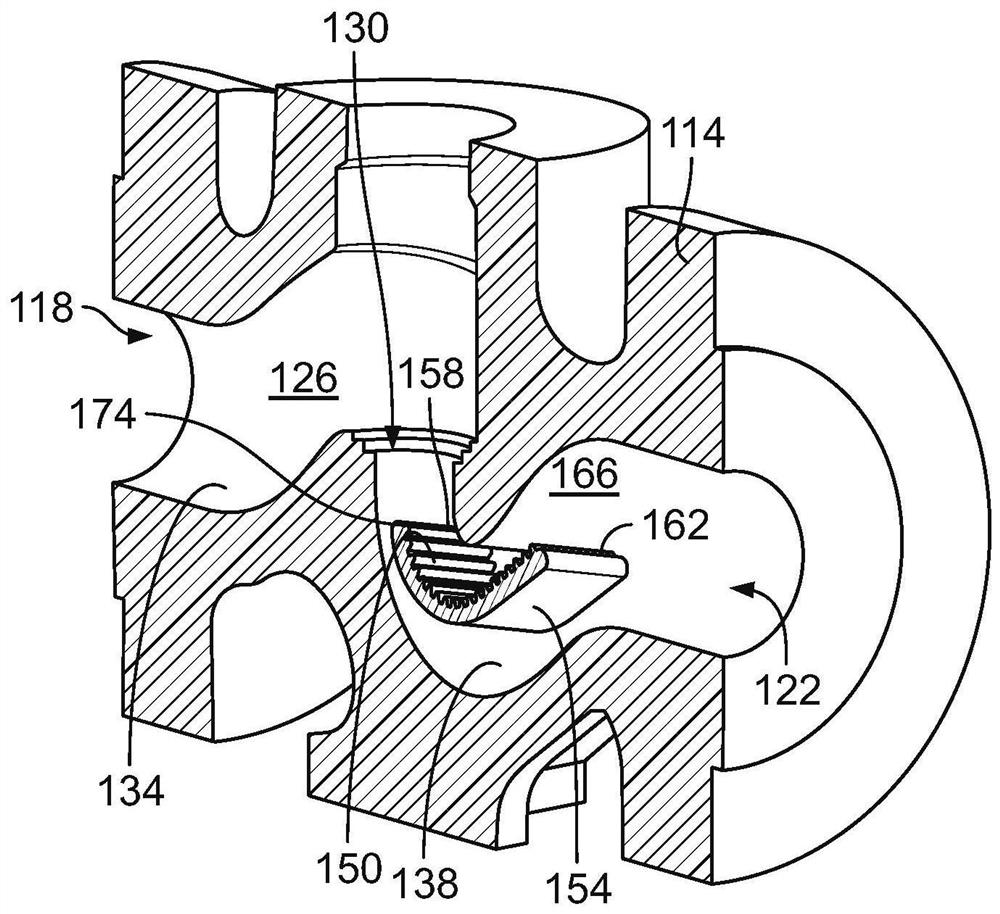

[0032] The present disclosure provides detection apparatus and methods for detecting wear due to cavitation or corrosion on flow control valve components. exist figure 1 In the present disclosure, a first exemplary flow control device 10 indicative of wear due to cavitation was constructed in accordance with the teachings of the present disclosure. The flow control device 10 is a sliding stem type control valve (e.g., HP series valve), which includes a ball valve body 14 defining an inlet 18, an outlet 22, and a flow path 26 connecting the inlet 18 and the outlet 22. Valve body 14 includes a valve port 30 defined between inlet 18 and outlet 22 , an inlet passage 34 , an outlet passage 38 , and flow vanes 42 . An inlet passage 34 connects the inlet 18 with the valve port 30 and an outlet passage 38 connects the valve port 30 with the outlet 22 .

[0033] A control member 46 is disposed in the flow path 26 and is movable relative to the valve port 30 in the valve body 14 bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com