Method for detecting firmness of carbon fiber accessory for automobile

A detection method and carbon fiber technology, applied in the direction of using stable tension/pressure to test material strength, measuring device, specific gravity measurement, etc., can solve the problems of inconvenient detection, many detection points, long time, etc., to shorten the product design cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

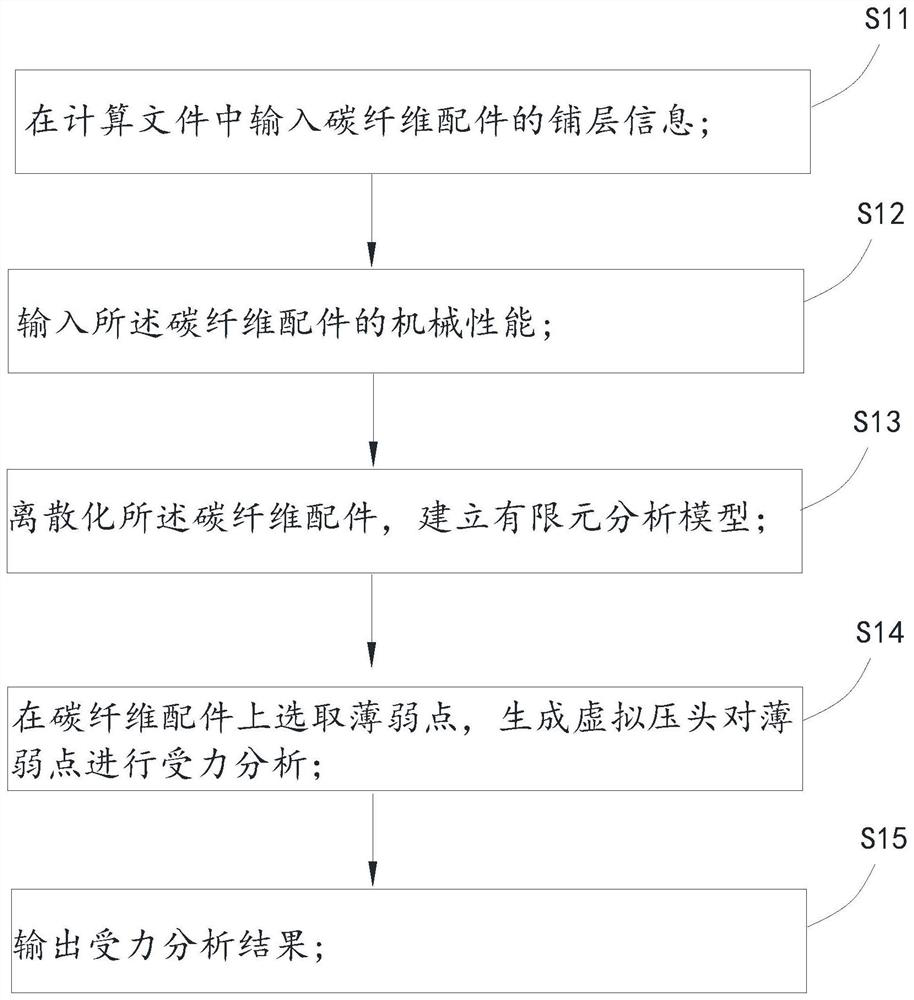

[0045] see Figure 1 to Figure 7 , the present embodiment provides a method for detecting the robustness of carbon fiber accessories for automobiles, comprising the following steps:

[0046] S11 Input the layup information of carbon fiber accessories in the calculation file, the layup information includes any one or more of the thickness of each layer of carbon fiber cloth, the type of carbon fiber material, and the direction of carbon fiber extension; wherein, the calculation file is submitted The finite element text file of the solver, the carbon fiber part includes multiple carbon fiber plies, and the carbon fiber part is formed by laminating multiple carbon fiber plies. The carbon fiber extension refers to the direction pointed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com