Plate material supplying apparatus

A technology of feeding device and feeding device, which is applied in the direction of feeding device, positioning device, storage device, etc., can solve problems such as shaking, unable to convey coils at high speed, and unable to fully exert punching capacity, etc., to achieve shaking suppression, high-speed effect of supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, examples of the present invention will be described with reference to the drawings, but the present invention is not limited to these examples.

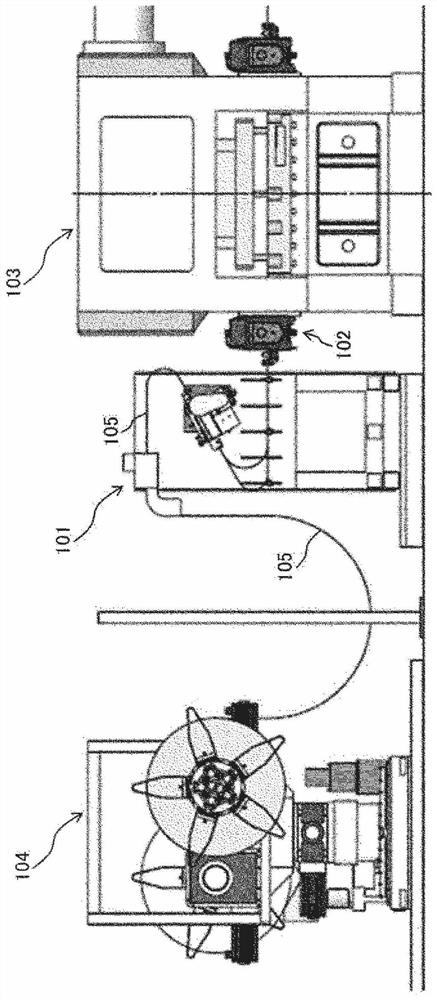

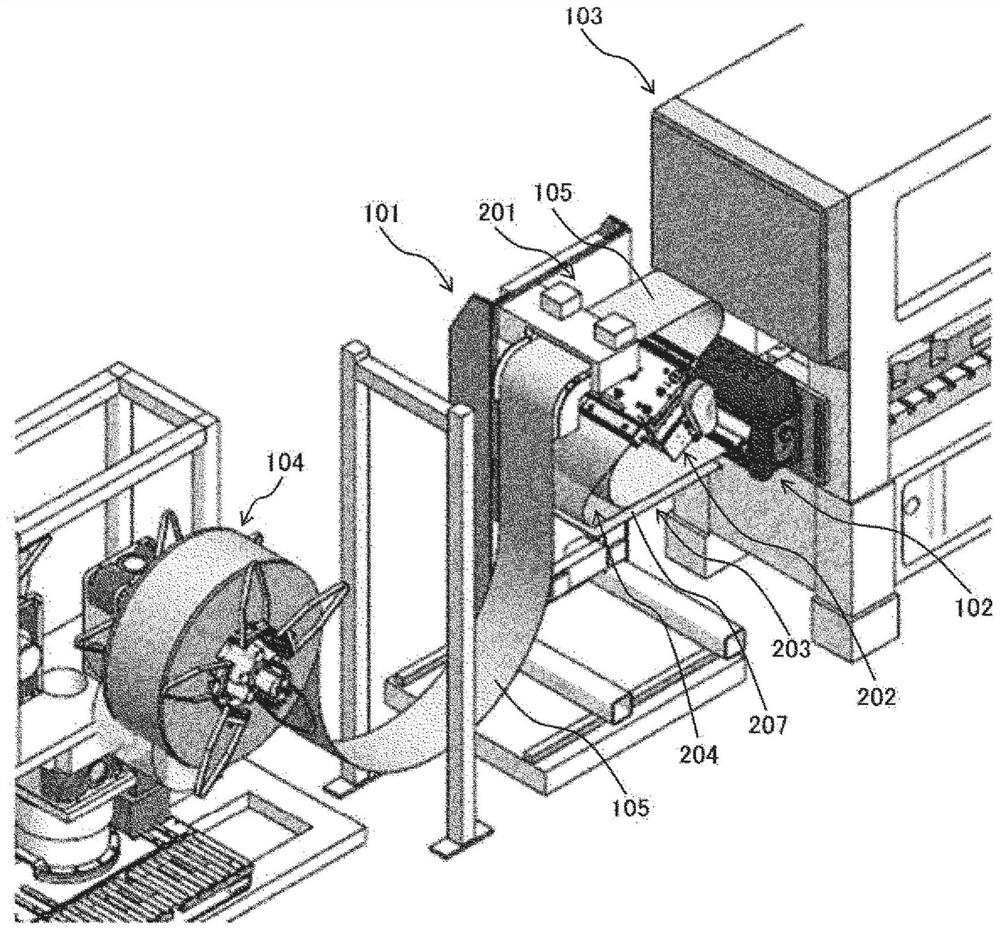

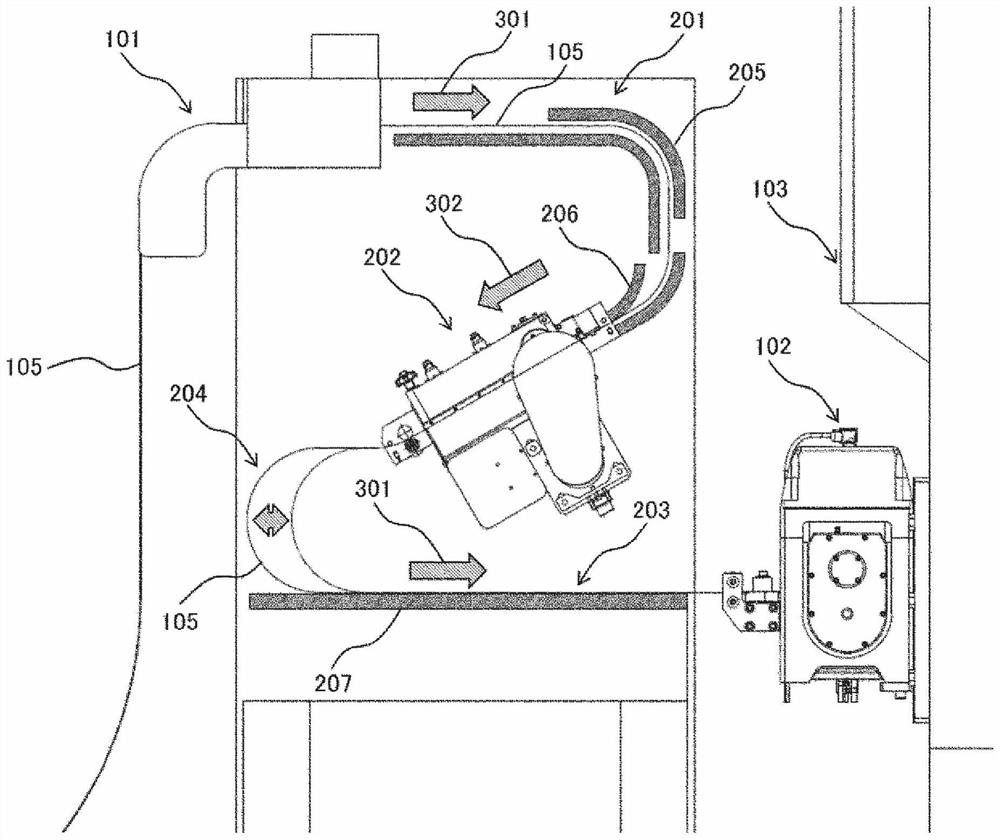

[0032] refer to Figure 1 to Figure 5 , the board material supply apparatus 101 which is one embodiment of this invention is demonstrated. Such as figure 1 and figure 2 As shown, in the press processing line, a sheet material 105 such as a coil is conveyed from an uncoiler 104 to a sheet material supply device 101, and the sheet material supply device 101 supplies the sheet material 105 to a sheet material feeding device 102, and the sheet material feeding device 102 performs punching processing, etc. A processing device such as a punching device 103 for processing transfers the plate material 105 intermittently. Such as Figure 3 ~ Figure 5 As shown, the sheet material supply device 101 has: an upper part 201 for conveying the sheet material 105 in the direction 301 of the sheet material feeding device 102; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com