Method for optimizing smoking limit value of electronic control diesel engine under working condition of rapid acceleration of accelerator

An optimization method and technology for diesel engines, applied in design optimization/simulation, biological neural network model, data processing applications, etc., can solve the problems of air intake response lag, diesel engine combustion and emission performance deviating from steady state conditions, deterioration, etc. The effect of reducing smoke and PM emissions, reducing test workload, and reducing test time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

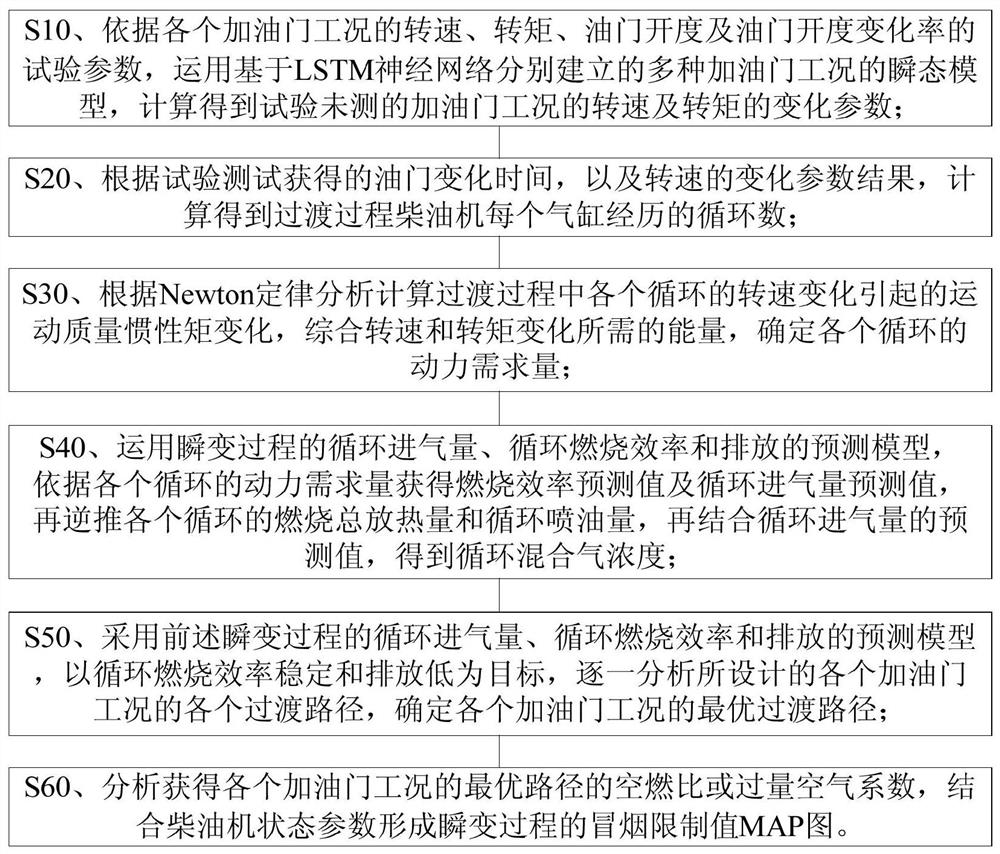

[0031] Such as figure 1 As shown, the optimization method of the electronic control diesel engine smoke limit under the throttle rapidly increasing working condition of the present embodiment 1 comprises the following steps,

[0032] Step S01, based on the LSTM neural network, respectively establish a variety of transient models of the accelerator operation conditions, wherein the accelerator operation conditions include a constant speed acceleration operation condition, a constant torque acceleration operation condition and an acceleration acceleration operation condition; wherein, This step can also adjust the position as required, such as being placed between step S05 and step S10;

[0033] Step S03, based on the LSTM neural network prediction algorithm combined with diesel engine steady-state test and transient test test data to establish a transient process cycle intake air volume, cycle combustion efficiency and emission prediction model; this step can also adjust the po...

Embodiment 2

[0048] This embodiment 2 will further illustrate.

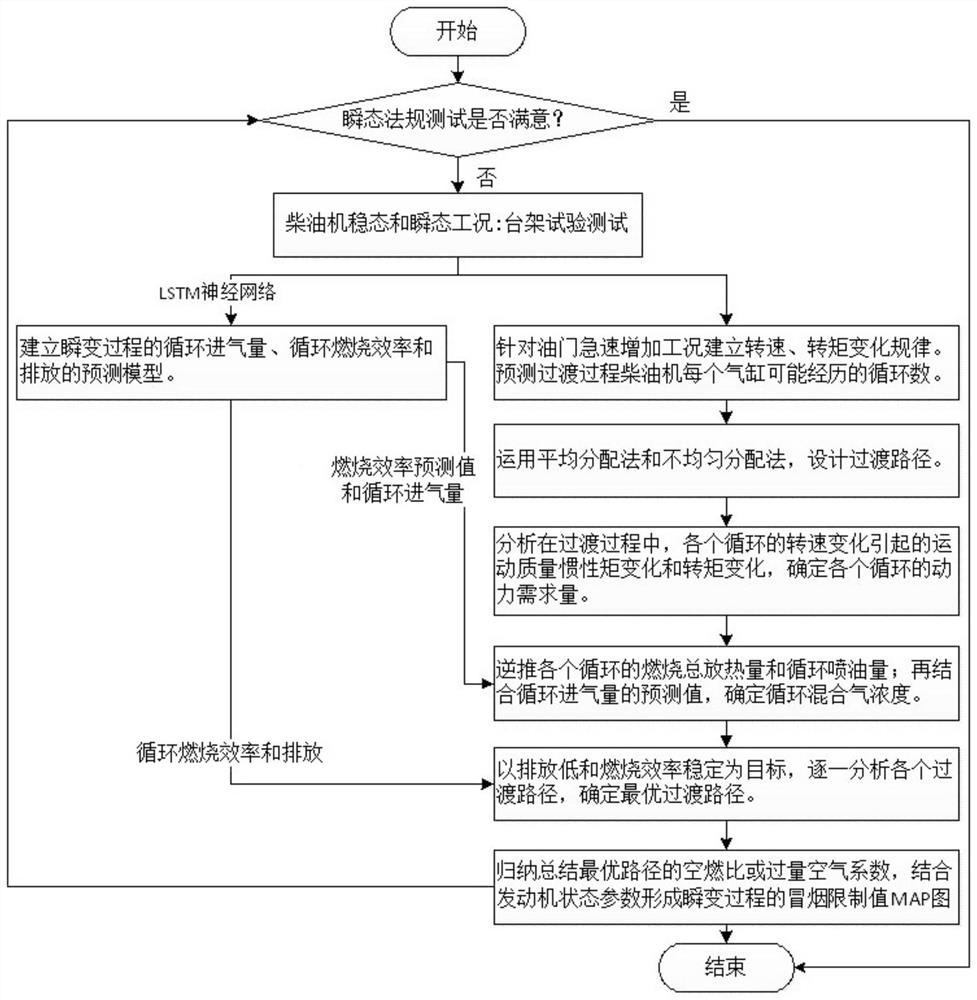

[0049] Such as figure 2 As shown, the optimization method of the electronic control diesel engine smoke limit under the throttle rapidly increasing working condition of the present embodiment 2 comprises the following steps,

[0050] (1) Combining the test data of diesel engine steady-state test (universal characteristics) and transient test (only torque change, only speed change, torque and speed change at the same time), based on the LSTM neural network prediction algorithm, the cycle of the transient process is established Predictive models for air intake, cycle combustion efficiency and emissions. This step is an existing technology, and the LSTM neural network can be used to predict NOx emissions according to the existing technology, so it will not be repeated here.

[0051] (2) Combine the genetic algorithm to optimize the initial value of the neuron weight of the LSTM neural network, and improve the defect of the ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com