Rapid sterilization equipment for surgical instruments

A technology for sterilizing equipment and surgical instruments, applied in the field of surgical instruments, can solve the problems of increasing the probability of medical gloves being cut, the scissors are grouped in the same part, the complicated situation of taking out and using, etc., so as to improve the stability of disinfection and movement. The effect of preventing and preventing cutting gloves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Figure 1 to Figure 6 Shown:

[0029] The invention provides a rapid sterilization equipment for surgical instruments,

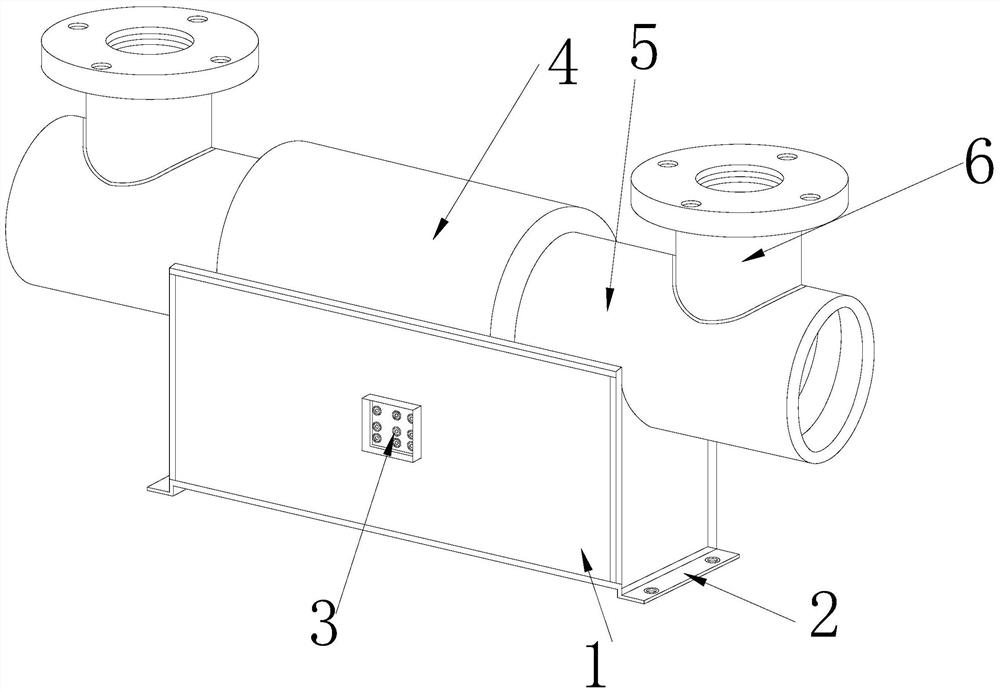

[0030] Its structure includes a distribution box 1, a tripod 2, a control terminal 3, a fixed cylinder 4, a sterilizer 5, and a cooling terminal 6. The distribution box 1 and the tripod 2 are integrated, and the control terminal 3 is embedded in the power distribution box. In the middle part of the box 1, the bottom cylinder 4 is embedded in the upper end of the distribution box 1, the sterilizer 5 runs through the center of the fixed cylinder 4, and the heat dissipation end 6 and the sterilizer 5 perform heat dissipation activities.

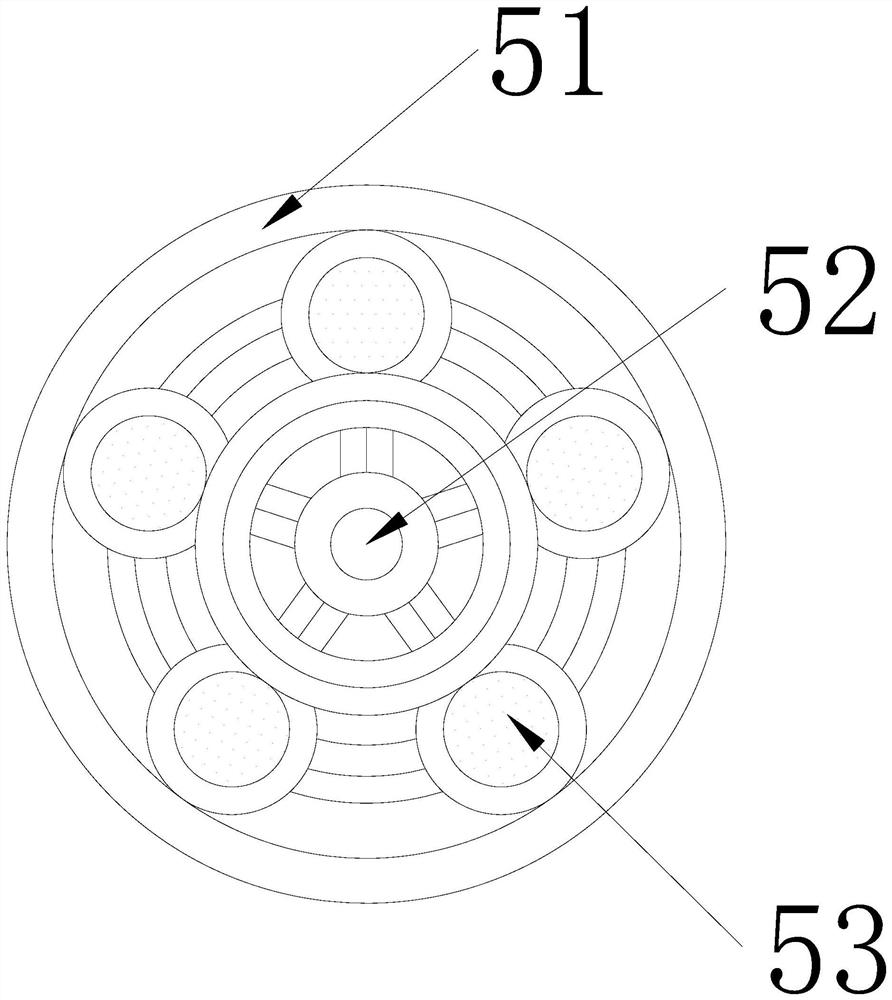

[0031] The sterilizer 5 is provided with a casing 51, a rotating wheel 52, and an inserter 53. The casing 51 and the rotating wheel 52 are at the same center point, and the inserter 53 is flexibly connected with the rotating wheel 52. There are five rotating wheels 52 on the outside, and corresponding balance bars are...

Embodiment 2

[0039] Figure 7 to Figure 9 Shown:

[0040] The invention provides a rapid sterilization equipment for surgical instruments,

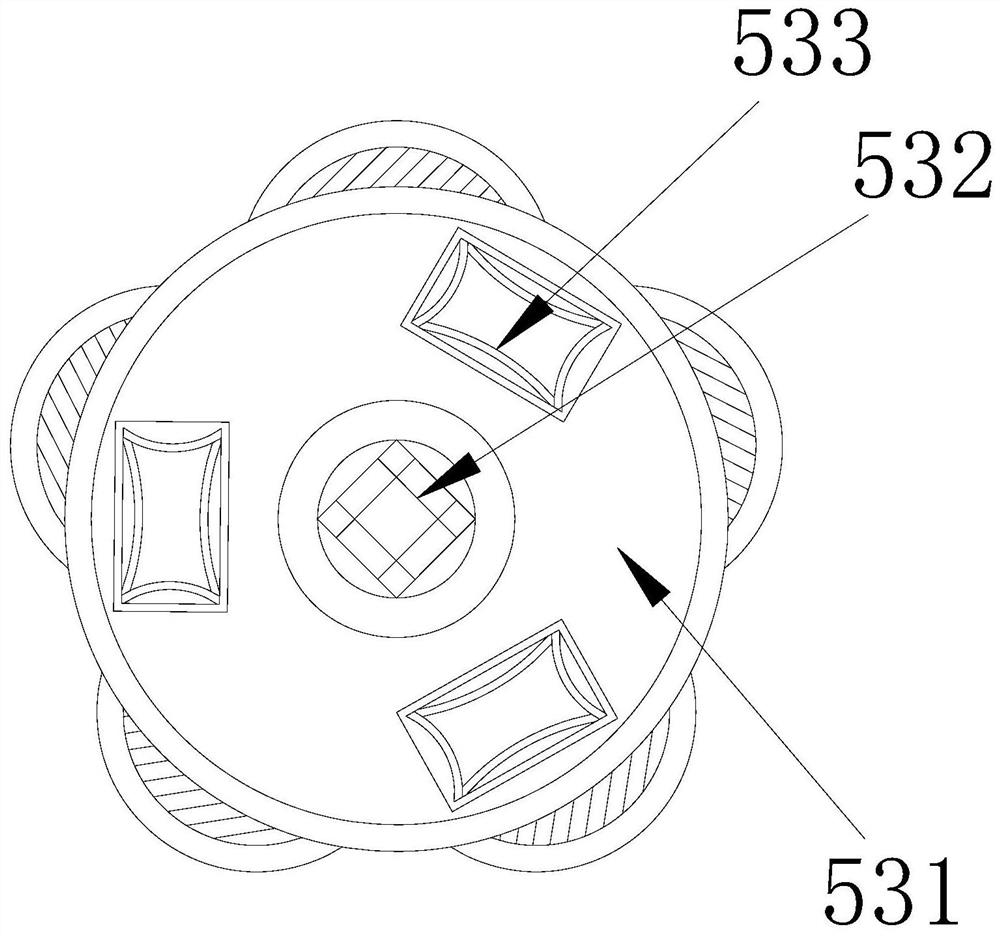

[0041] Its structure includes that the positioning wheel 532 is provided with a solid plate c1, a spacer c2, a base c3, a push rod c4, and a connector c5, the solid plate c1 and the spacer c2 are integrated, and the base a3 is embedded in the spacer c2 Among them, the ejector rod c4 is movably connected with the base c3, and the connector c5 is movably matched with the ejector rod c4. The connector c5 is in the shape of a trapezoid, and it is wide at the top and narrow at the bottom. The connection The device c5 can effectively realize its upper end to maintain the activity stability of each part under the state of its upper width and lower housing.

[0042] Wherein, the connector c5 is provided with a connection groove c51, a limit end c52, an adsorption end c53, and a contact end c54, the connection groove c51 and the limit end c52 are integrated,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com