A processing technology and processing system of a circuit fixing board

A processing technology and processing system technology, applied in the field of sheet metal parts processing, can solve the problem of low processing accuracy of circuit fixing boards, and achieve the effects of preventing dimensional changes, ensuring processing accuracy, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

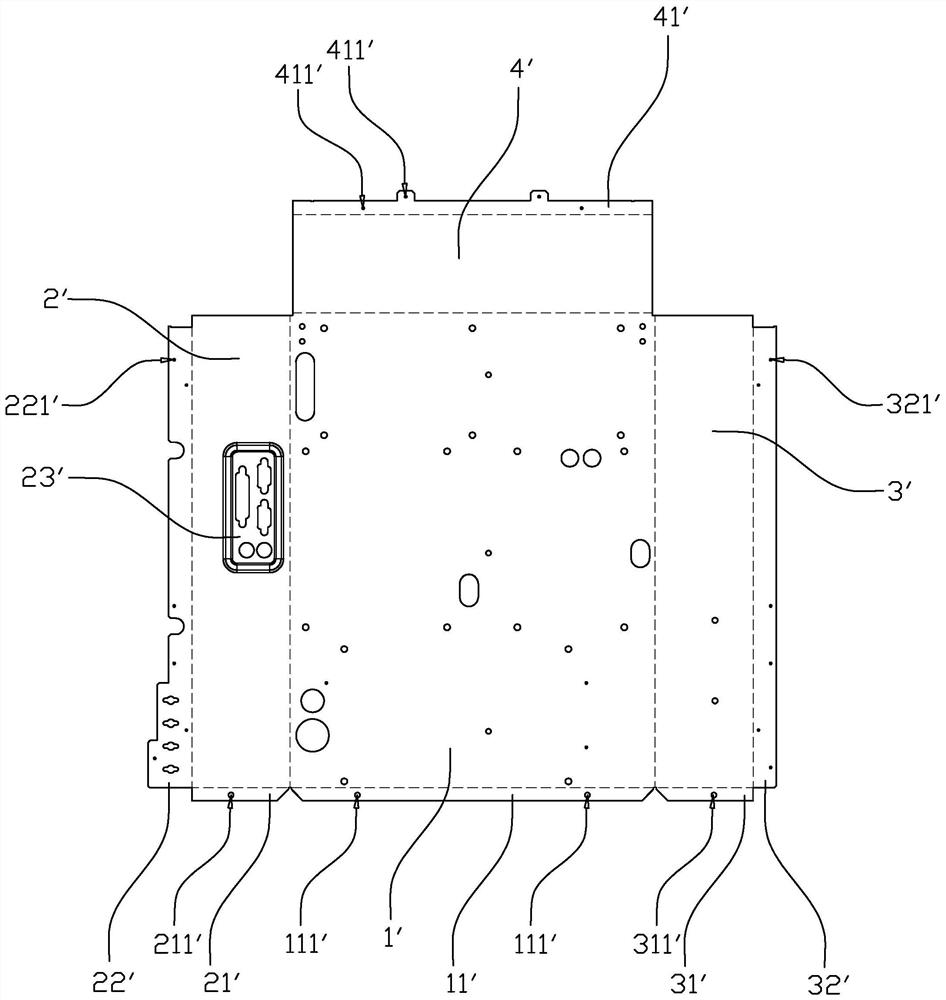

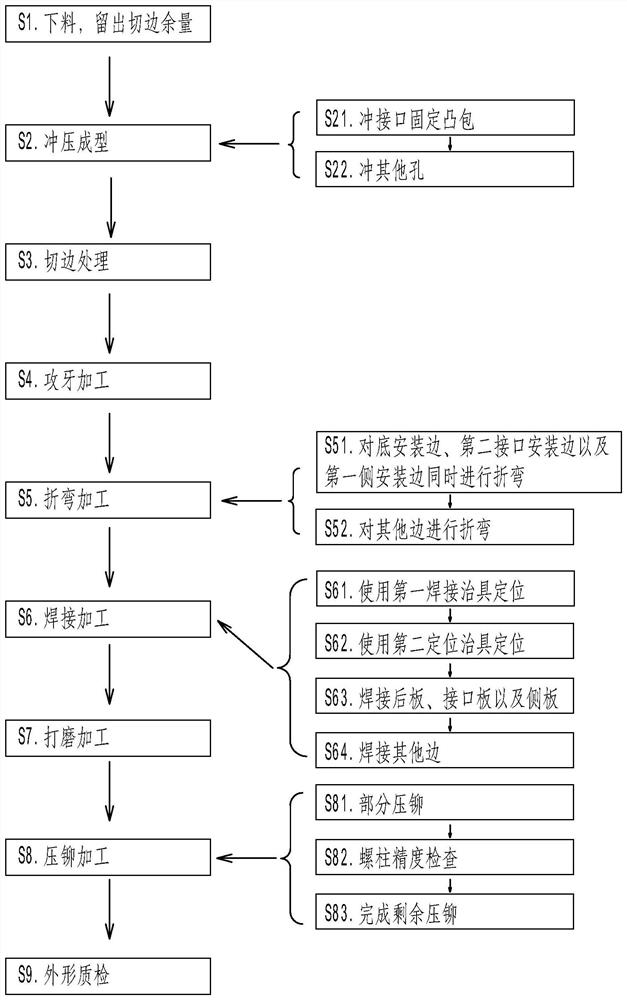

[0069] The embodiment of the present application discloses a process for processing a circuit fixing board. refer to figure 2 and image 3 , a processing technology of a circuit fixing board, comprising the following steps:

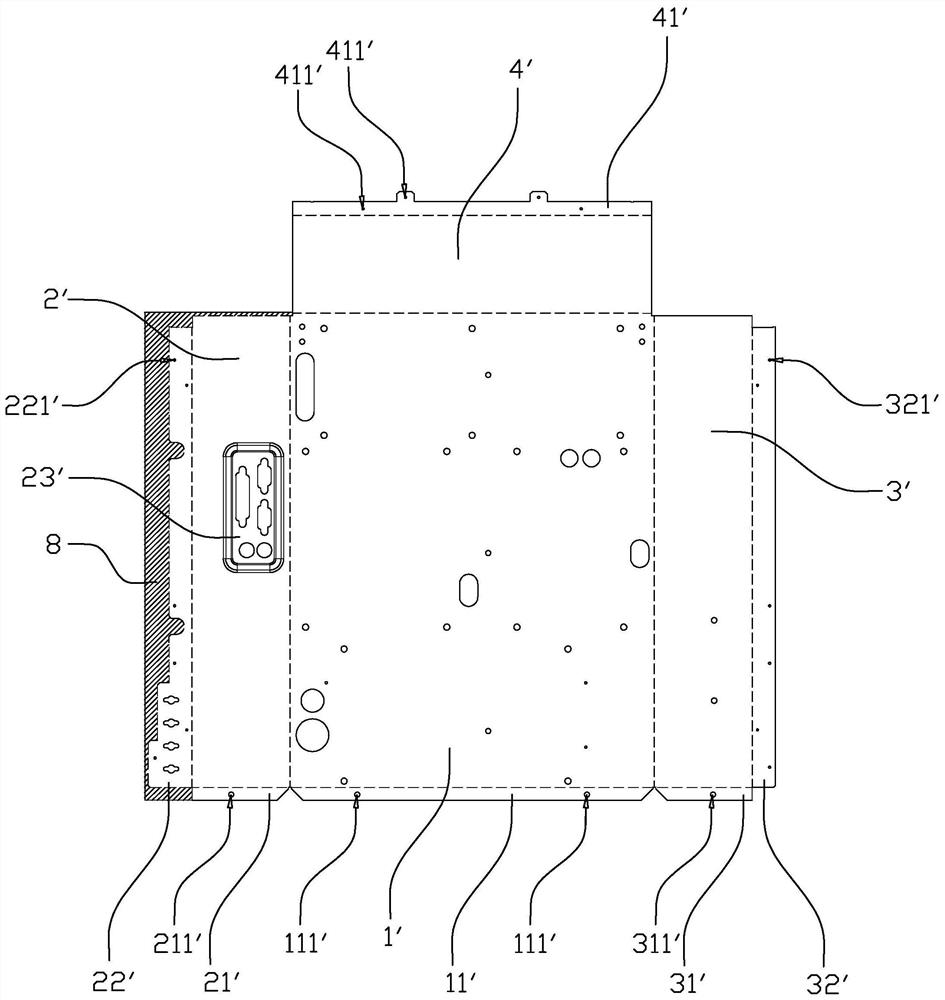

[0070] S1. Cut the whole sheet metal plate according to the unfolded size of the sheet metal, and at the same time leave a trimming allowance of 8 at the position of the second interface installation side 22'; the process of cutting the whole sheet metal plate at the blanking station, Unloading can be done on a laser cutting machine or on a number punching machine. In the first embodiment, the entire sheet metal is processed by blanking on a number punching machine according to the expanded size of the sheet metal.

[0071] S2. stamping and forming the interface board 2'; wherein, the process of stamping the interface board 2' at the general punching station can be divided into the following two steps;

[0072] S21. Use the interface convex hull die ...

Embodiment 2

[0097] The embodiment of the present application discloses a processing system for a circuit fixing board. A processing system for a circuit fixing board, comprising a blanking station for cutting a whole sheet metal plate into the shape of a part, a general punching station and a tapping station for punching out correspondingly shaped convex hulls or through holes , bending station, welding station, grinding station, pressure riveting station and quality inspection station.

[0098] The welding station includes a welding machine for welding, a first welding fixture 1 for positioning the bottom mounting edge 11', the first interface mounting edge 21' and the first side mounting edge 31', and a rear mounting edge for positioning. 41', the second interface mounting edge 22' and the second side mounting edge 32' for positioning the second soldering fixture 2, after the circuit fixing board is bent, there is a circuit fixing cavity 9, and the first soldering fixture 1 is located i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com