A multi-stage telescopic casing device

A telescoping sleeve and sleeve technology, which is applied to the connection of rods, connecting components, weapons without explosives, etc., can solve the problems of affecting recovery, the force of throwing is not too large, and affecting the use effect, so as to achieve convenient recovery and guarantee The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

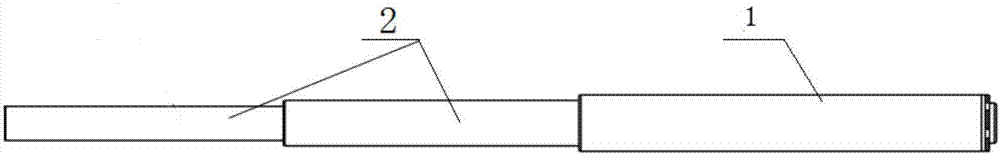

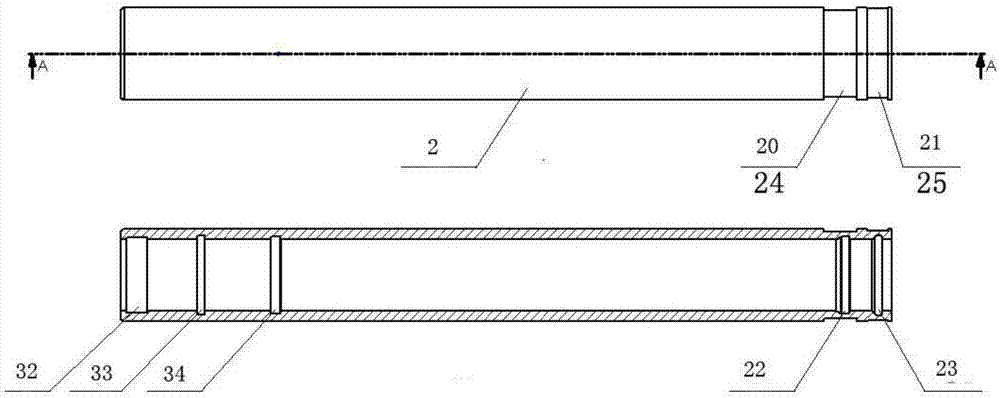

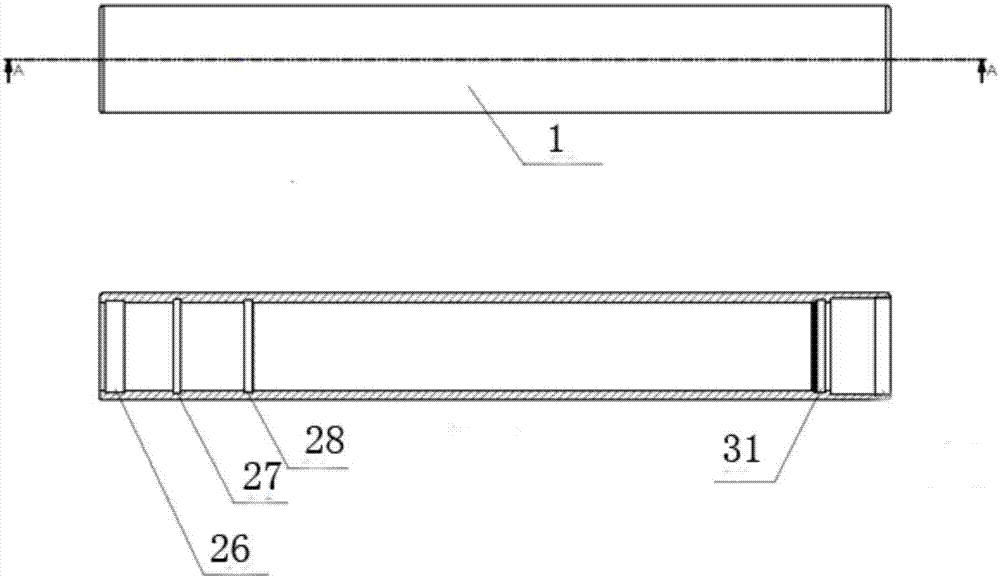

[0028] Such as Figure 1-7 The multi-stage telescopic sleeve device shown includes an outer tube 1, a set of inner tubes 2, a multi-petal buckle assembly 3, a positioning spring 4, a multi-petal expansion coil spring 5, an opening guide rod 6 and an opening button 7 , the bottom end of the outer tube 1 is equipped with an opening button 7 for controlling the expansion and contraction of the casing, the opening guide rod 6 is arranged in the outer tube 1 and connected with the opening button 7, the inner tube 2 is assembled in the outer tube 1, and the inner tube 2 The outer tube 1 at the bottom is equipped with a multi-petal buckle assembly 3, a positioning spring 4 and a multi-petal spring coil spring 5, and the multi-petal buckle assembly 3 is composed of two or more snap blocks 8 in an annular array Composition, the top of the buckle block 8 is a buckle conical arm 35, the middle part of the buckle block 8 has a buckle limit protrusion 9 outside, and a buckle locking protru...

Embodiment 2

[0038] like Figure 1-10 A multi-stage telescopic sleeve device shown, on the basis of Embodiment 1, the telescopic sleeve device has two sets of inner tubes 2, and a multi-petal buckle assembly 3 and a positioning spring are installed at the joints of the two sets of inner tubes 2 4 and a multi-lobe-shaped coil spring 5, the multi-lobe buckle assembly 3 is composed of two or more buckle blocks 8 in an annular array, and the middle part of the buckle block 8 has a buckle limit protrusion on the outside 9. There is a buckle locking protrusion 10 on the outside of the tail of the buckle block 8, and a positioning spring slot 11 and an expansion coil spring slot 12 are arranged on the inside of the buckle block 8. The positioning spring 4 is installed in the positioning spring slot 11 Inside, the multi-lobed coil spring 5 is installed in the coil spring slot 12 .

[0039] On the basis of contraction in Example 1, when there are two sets of inner tubes 2 and the second inner tube...

Embodiment 3

[0042] like figure 1 In the shown multi-stage telescopic sleeve device, on the basis of Embodiment 1 or 2, the outer tube 1 and the inner tube 2 are square sleeves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com