Large armrest of rear-row seat

A technology for rear seats and armrests, applied in the direction of armrests, vehicle seats, vehicle parts, etc., can solve the problems of lowering the installation quality of armrests, affecting the riding experience of rear passengers, and magnifying the amount of shaking, etc., achieving broad market application prospects , Improve the comfort experience, the effect of high locking strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

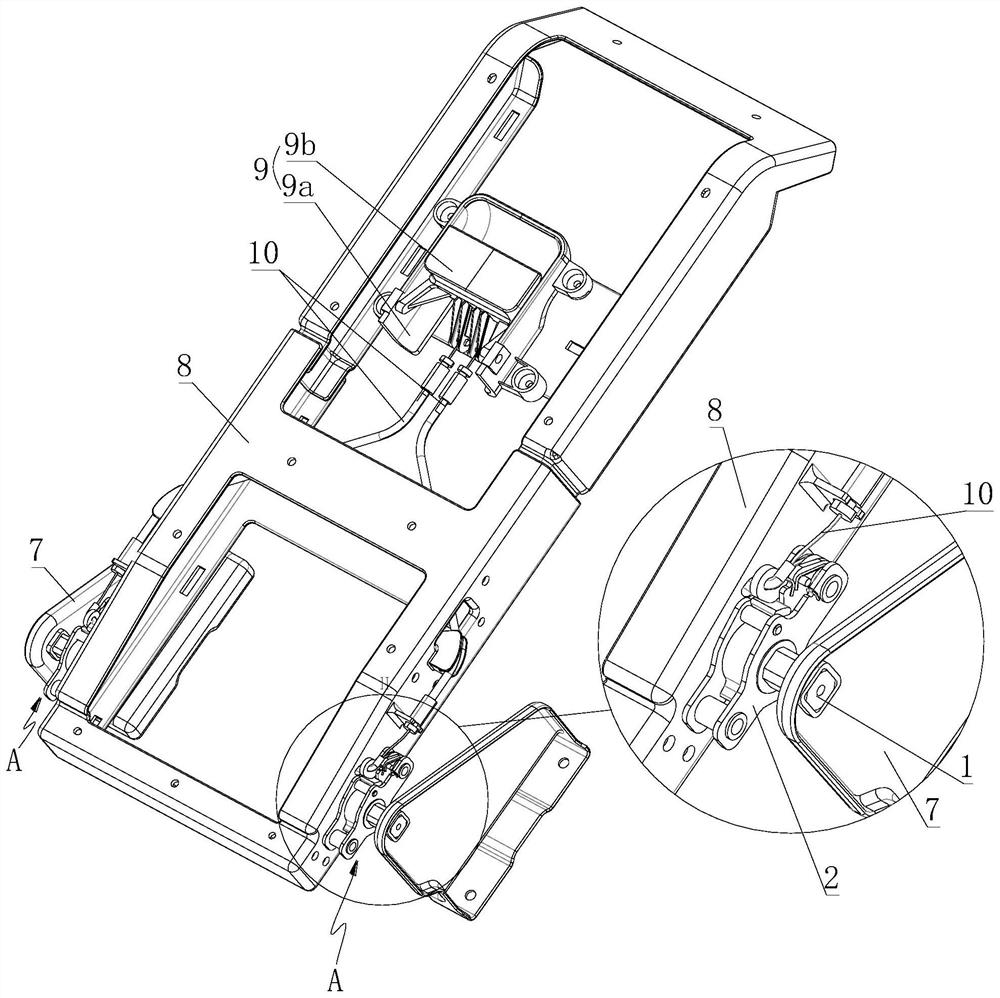

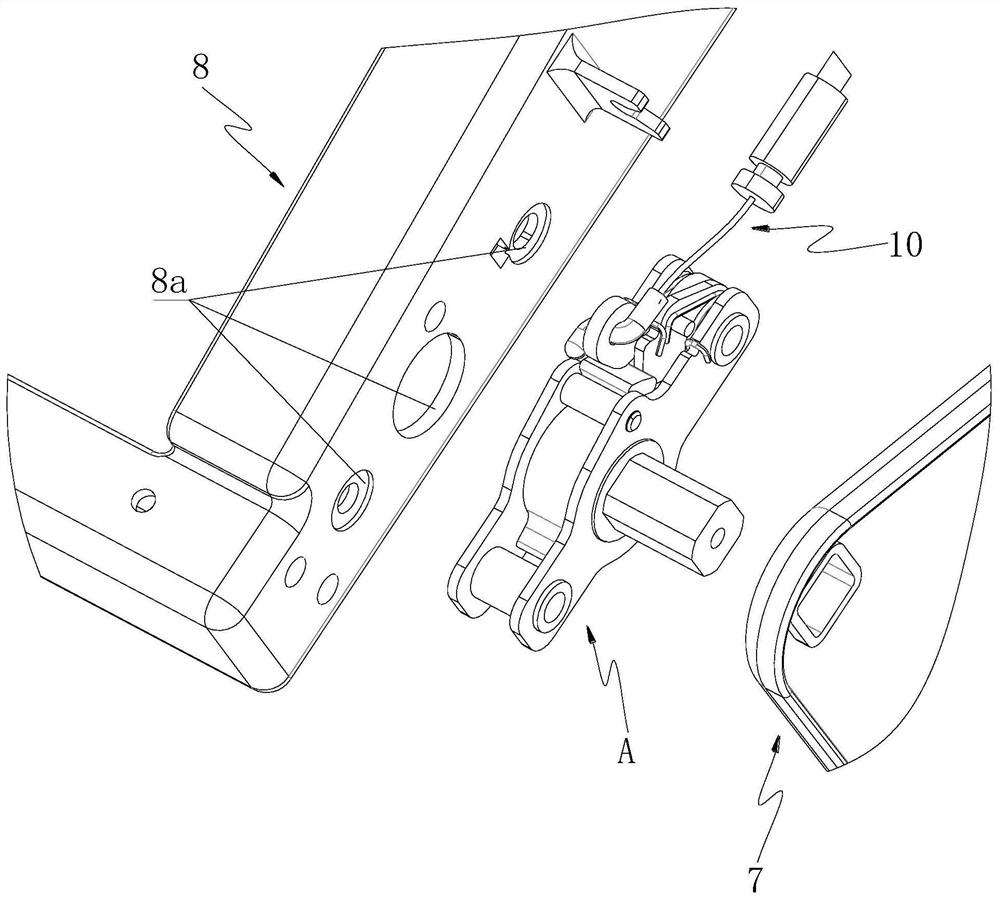

[0034] like figure 1 and 2 As shown, a large armrest of a rear seat involves components including: a support 7 , a locking hinge A, a large armrest frame 8 , an unlocking component 9 , and a cable 10 . Wherein, the support 7 is used to be fixedly connected with the frame of the seat, and there are two groups in total, which are respectively located on both sides of the inner end of the large armrest frame 8 . The locking hinge A can not only make the large armrest frame 8 rotatably assembled on the support 7, but also ensure that the large armrest is locked on the backrest in a folded state.

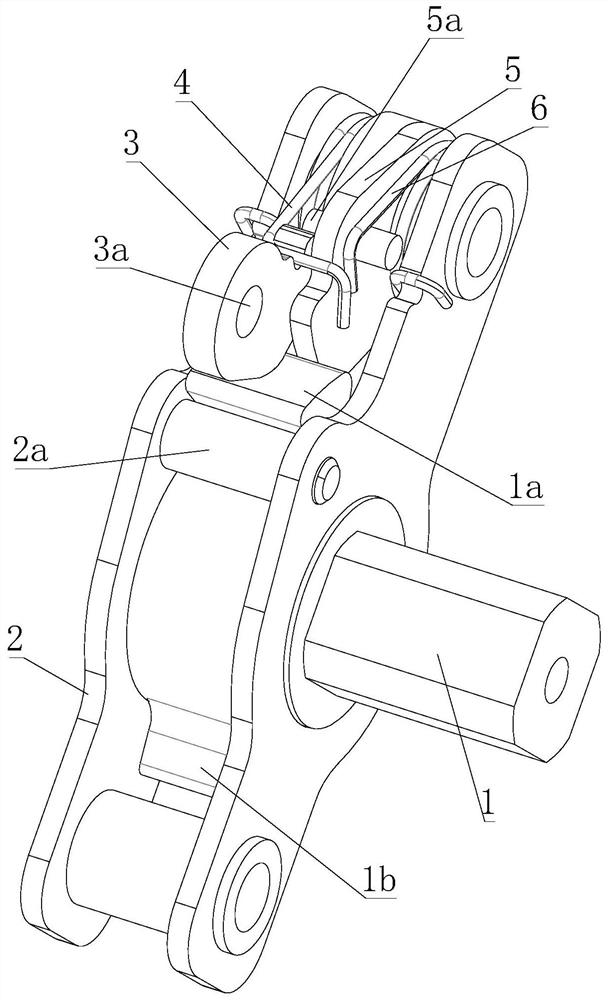

[0035] Another example image 3 , 4 As shown in and 5, in this embodiment, the locking hinge A includes a fixed shaft component 1 and a movable bracket 2 that is rotatably socketed with the fixed shaft component 1, wherein the fixed shaft component 1 is fixedly asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com