Hard pipe and nut assembling mechanism

An assembly mechanism and hard tube technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low efficiency and high scrap rate of hard tubes and nuts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

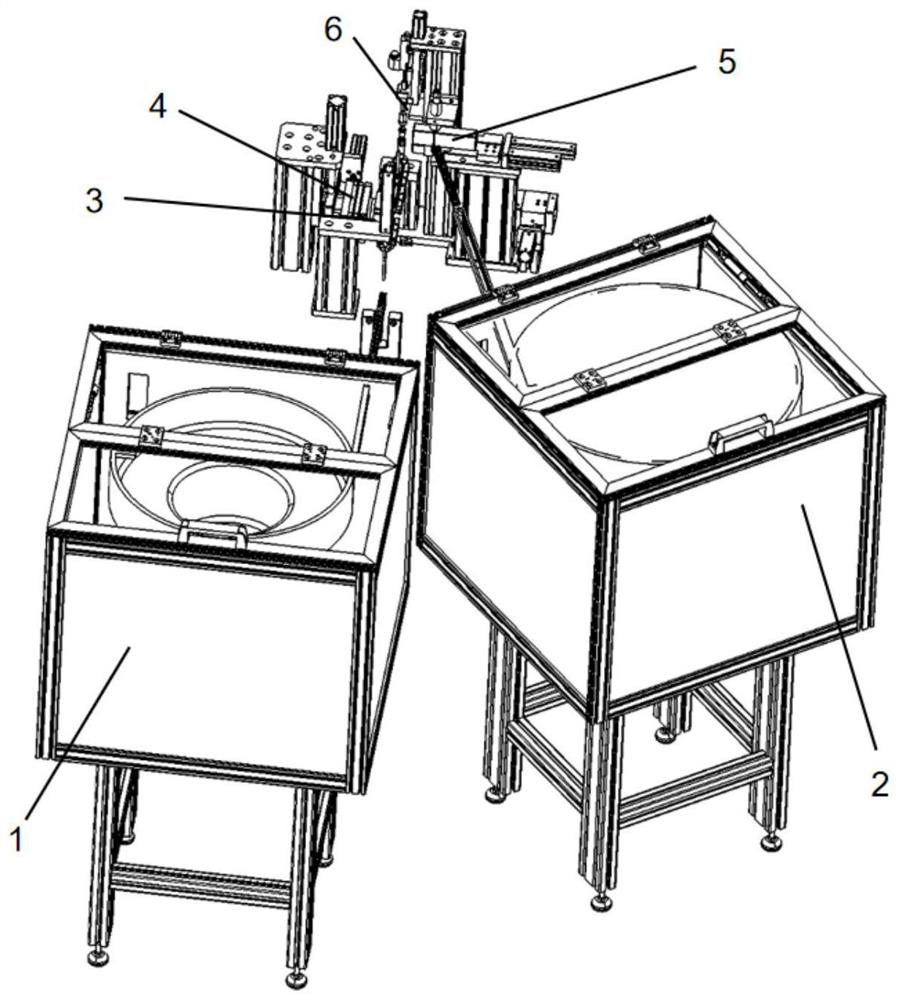

[0036] A hard tube and nut assembly mechanism such as figure 1 As shown, it includes a hard tube loading box 1, a nut loading box 2, a hard tube pulling device 3, a hard tube rotation and translation device 4, a nut flat pushing device 5 and a hard tube height detection device 6;

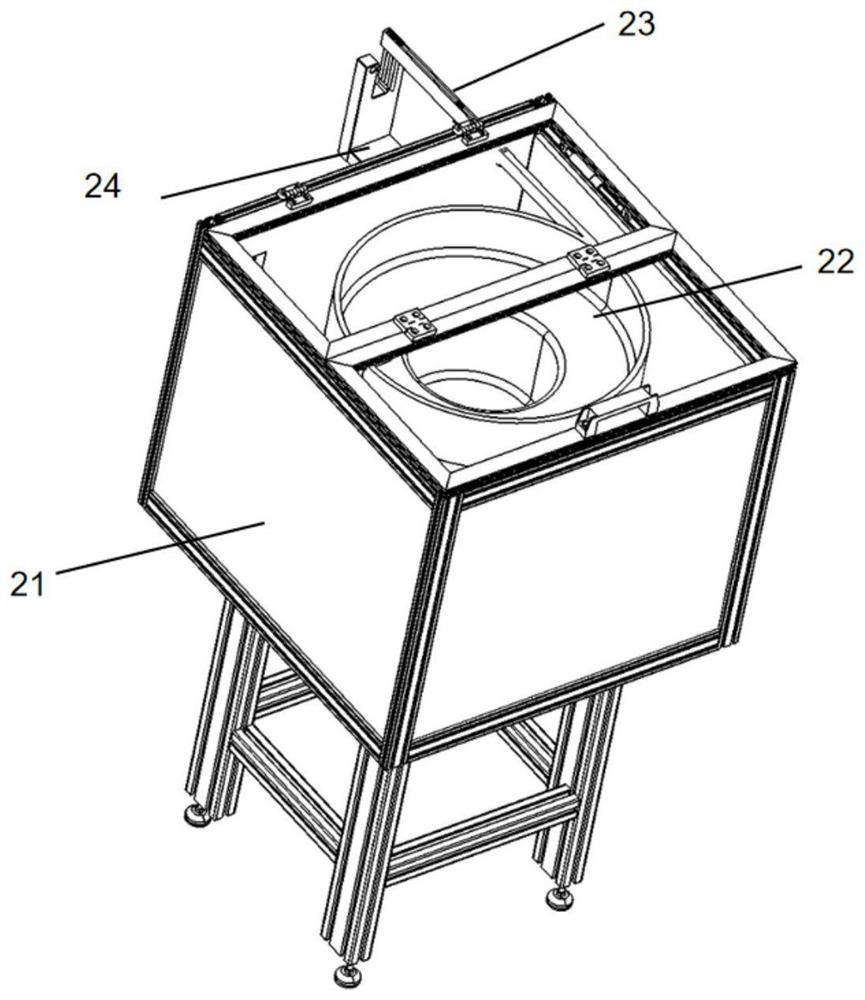

[0037] Hard tube loading box 1, such as figure 2 As shown, it includes soundproof shelf equipment I 21, hard tube vibrating plate 22, hard tube feeding frame 23 and direct vibration mounting plate 24, hard tube vibrating plate 22 is arranged in soundproof shelf equipment I 21, one end of which is connected to hard tube feeding The rack 23 is connected, and the hard tube placed on the hard tube vibrating plate 22 can be transferred to the hard tube feeding rack 23 through the hard tube vibrating plate 22;

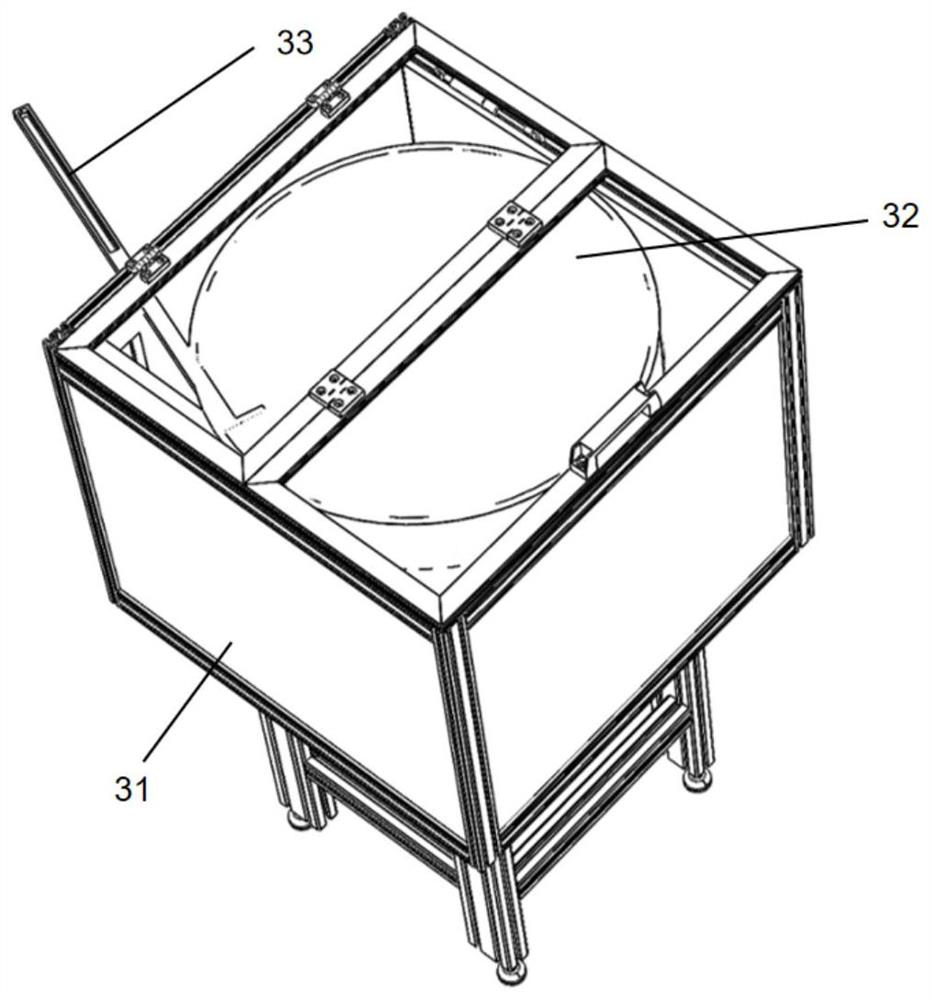

[0038] Nut loading box 2, such as image 3 As shown, it includes soundproof shelf equipment II 31, nut vibrating plate 32 and nut feeding rack 33. The nut vibrating plate 32 is arranged in the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap