Ceramic sheet flatness control device and use method

A ceramic thin plate and control device technology, which is applied in the direction of construction and building construction, can solve the problems of complex installation and inability to effectively control the flatness of ceramic thin plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

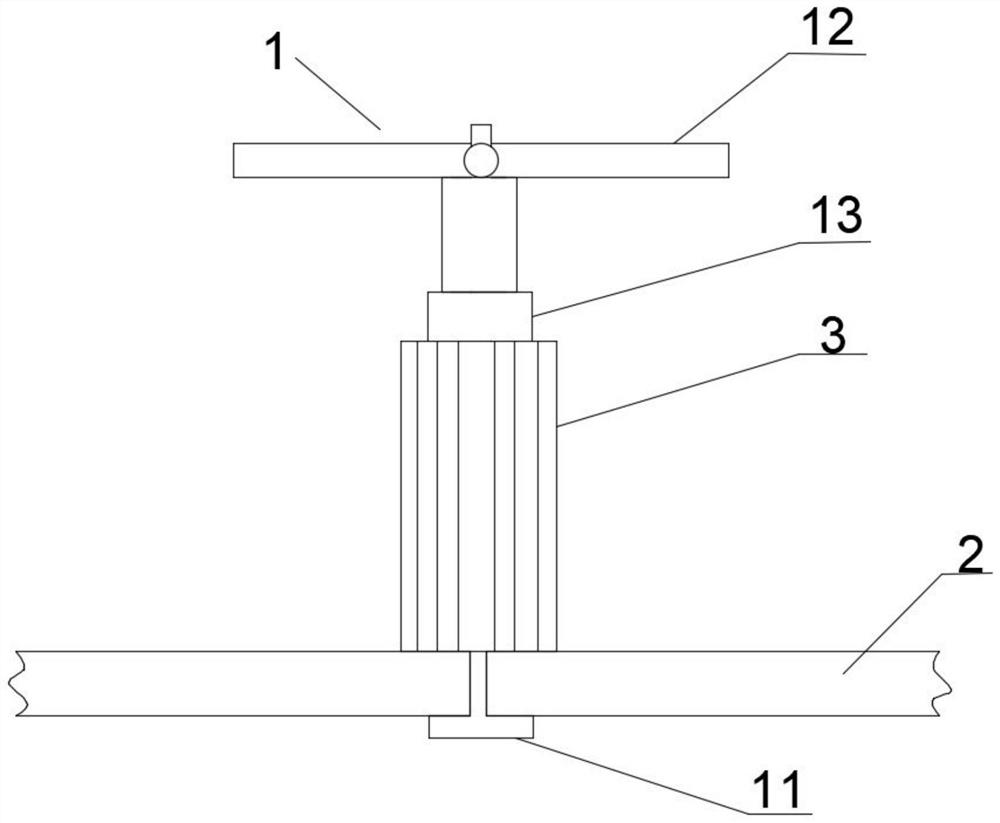

[0036] Such as figure 1 As shown, it is an embodiment of the present invention, a device for controlling the flatness of a thin ceramic plate, including an upper part 1 and a lower sleeve 3, the upper part 1 includes a test strip 11, and the test strip 11 is installed at the lower end of the upper part 1, The test strip 11 is adapted to pass through two sets of ceramic thin plates 2 and be rotated and clamped under the two sets of ceramic thin plates 2;

[0037] The lower sleeve 3 is installed on the upper part 1 and is suitable for rotating against the upper ends of the two sets of ceramic thin plates 2 .

[0038] Further, the upper part 1 includes a handle part 12, the handle part 12 is located at the upper end of the upper part 1, the lower end of the handle part 12 is installed with an upper post 13, the outer surface of the upper post 13 is provided with external threads, and the lower sleeve 3 is provided with an inner thread. thread, the lower sleeve 3 is threadedly co...

Embodiment 2

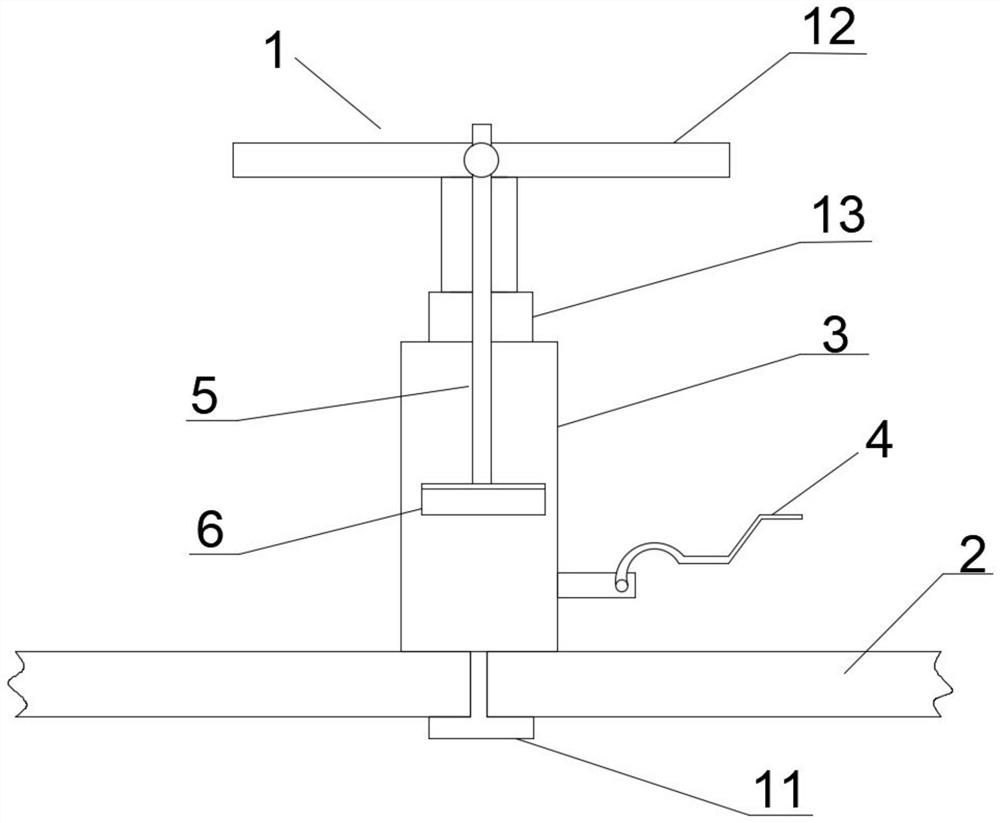

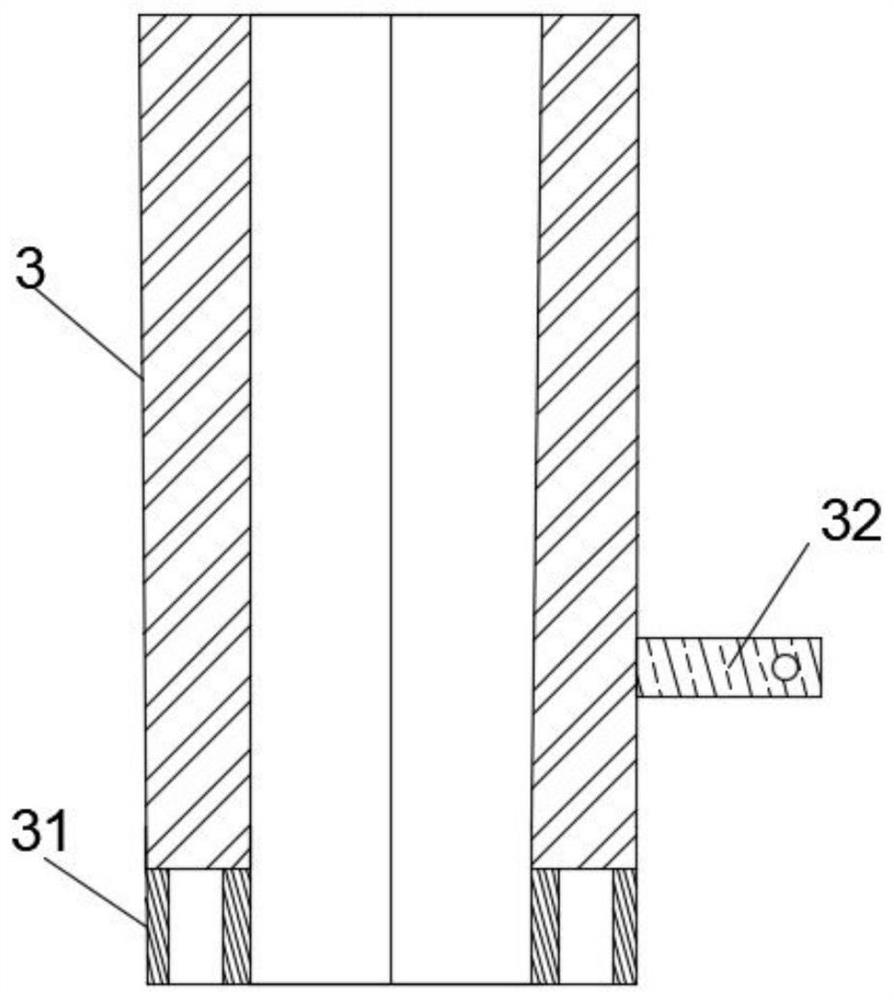

[0042] Such as Figure 2 to Figure 6 Shown is another embodiment of the present invention, on the basis of Example 1, the lower end of the lower sleeve 3 is provided with an annular portion 31, the lower end of the annular portion 31 is arranged horizontally, and the lower end of the annular portion 31 is provided with a cavity , the ring portion 31 is suitable for fitting on the upper ends of the two sets of ceramic thin plates 2 during installation.

[0043] In order to facilitate the installation of construction personnel, when a large number of this device needs to be installed, it is very easy to generate repetitive labor and cause inefficiency. By installing a connecting column 32 outside the lower sleeve 3, the connecting column 32 is provided with a mounting hole, and a rotating shaft is installed in the mounting hole. The wrench 4 is detachably connected to the mounting hole by turning the wrench 4, and the turning wrench 4 is suitable for adjusting the position of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com