Test method for accurately detecting vertical residual stress of rail web of steel rail

A technology of residual stress and testing method, applied in measuring devices, force/torque/work measuring instruments, instruments, etc., can solve the problem of inability to accurately describe the expansion of rail waist instability, large error range, and inability to measure vertical residual stress questions of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] A test method for accurately detecting the vertical residual stress of rail waist.

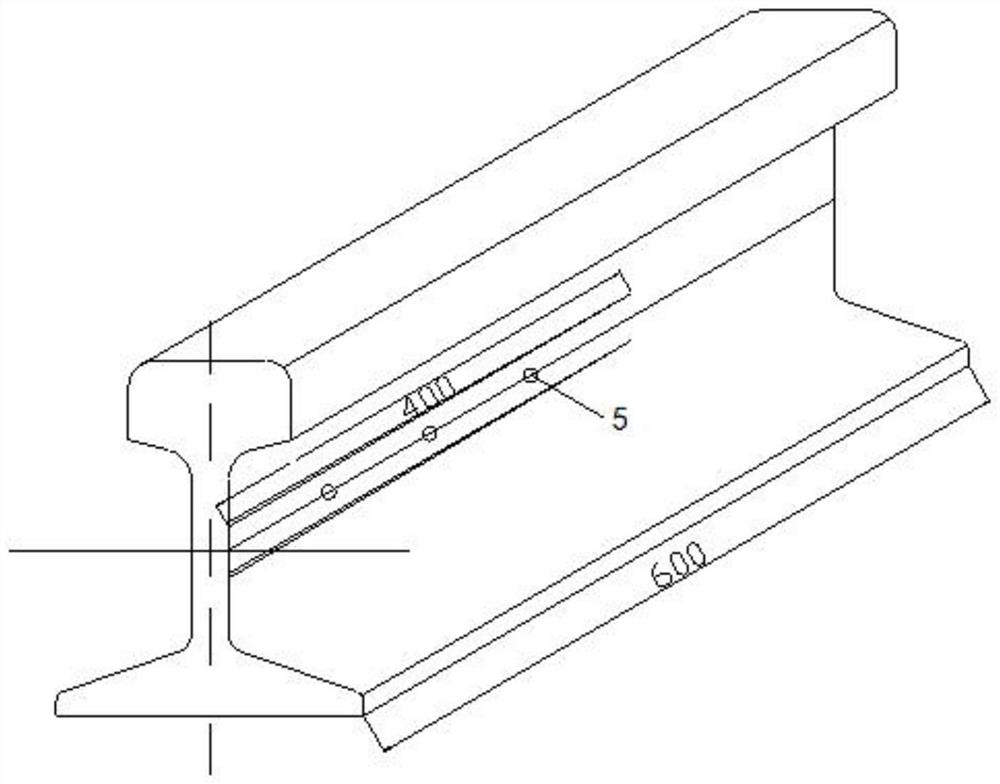

[0023] (1) Select a section of 610mm long test rail, lay the rail on its side, the side of the rail head and the foot of the rail are in contact with the ground, and properly raise the side of the rail head so that the rail waist is parallel to the ground and is in a horizontal state;

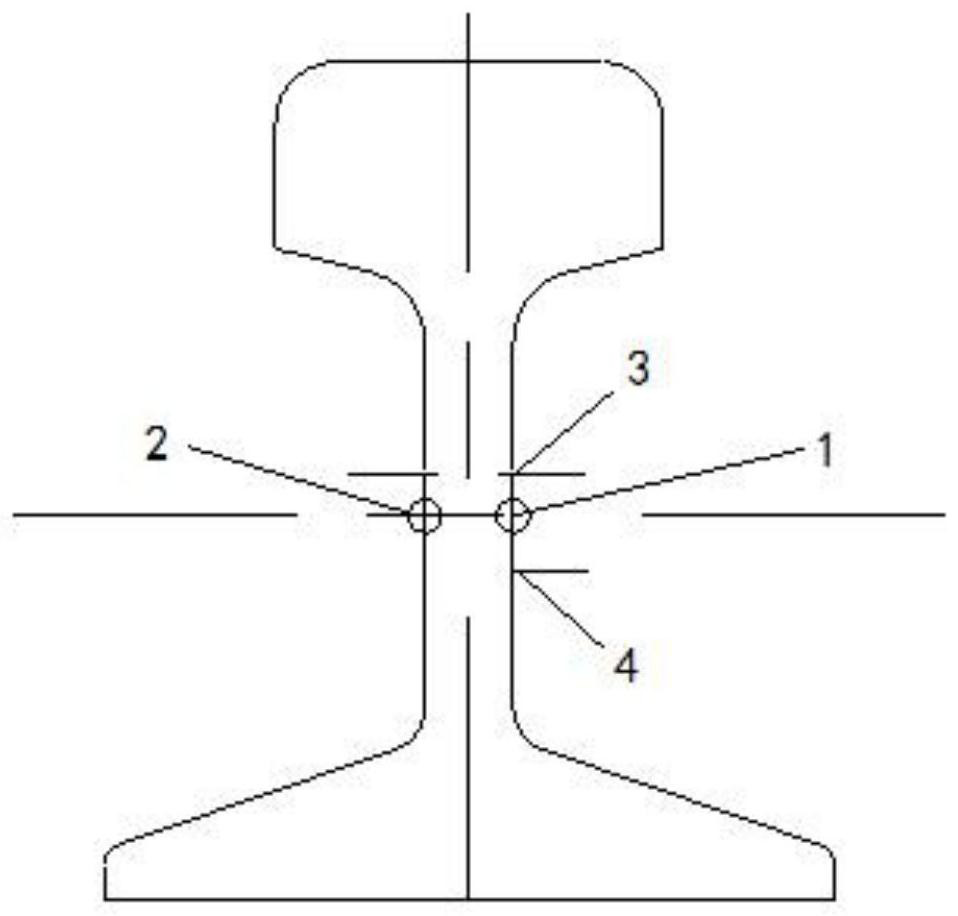

[0024] (2) Find the vertical midpoint of the rail waist at both ends of the rail waist, and connect the two points with a straight line. The straight line should be parallel to the bottom of the rail, that is, the vertical center line of the rail waist, marked It is the first straight line 1. Similarly, on the other side of the rail waist, make a second vertical center line of the rail waist, which is marked as the second straight line 2 (see figure 1 );

[0025] (3) Starting from one end of the rail, mark a point every 100mm along the first straight line (both ends are not marked), and mark 3 points. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com