Plug-in connector with improved protection against high-voltage flashovers

A technology for plugging connectors and pressing plates, which is applied in the direction of connection, connection device components, and contact assembly/disassembly, etc. It can solve problems such as short circuit and distortion, increase leakage current, simplify embedding, and avoid flashover. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

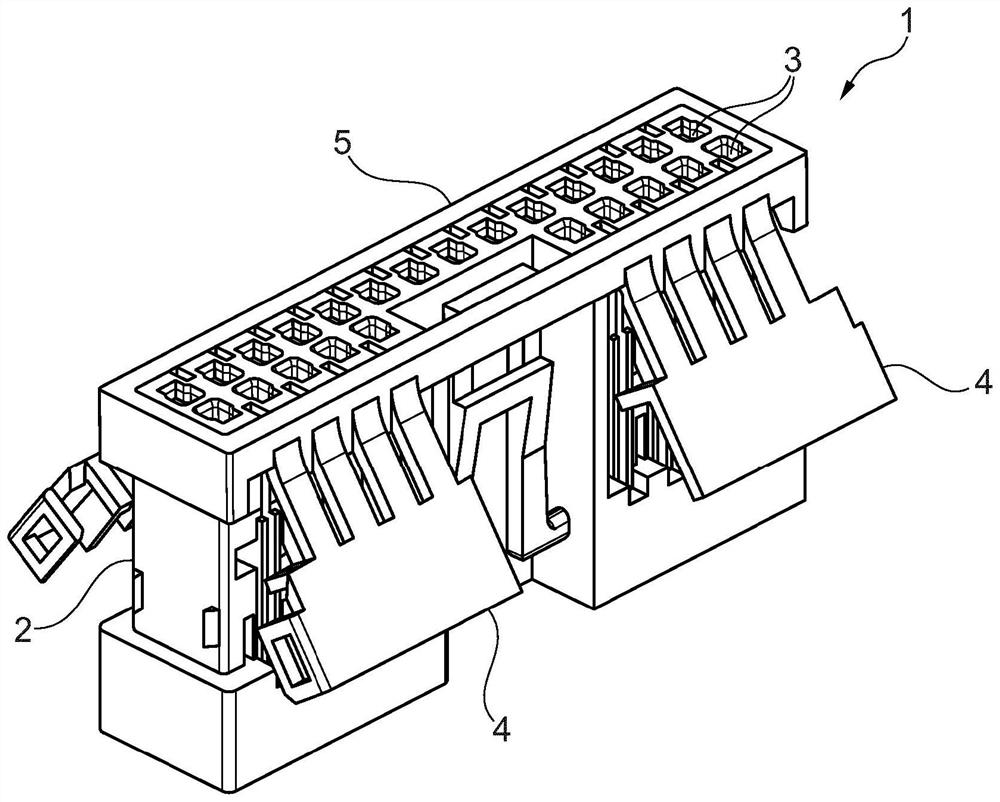

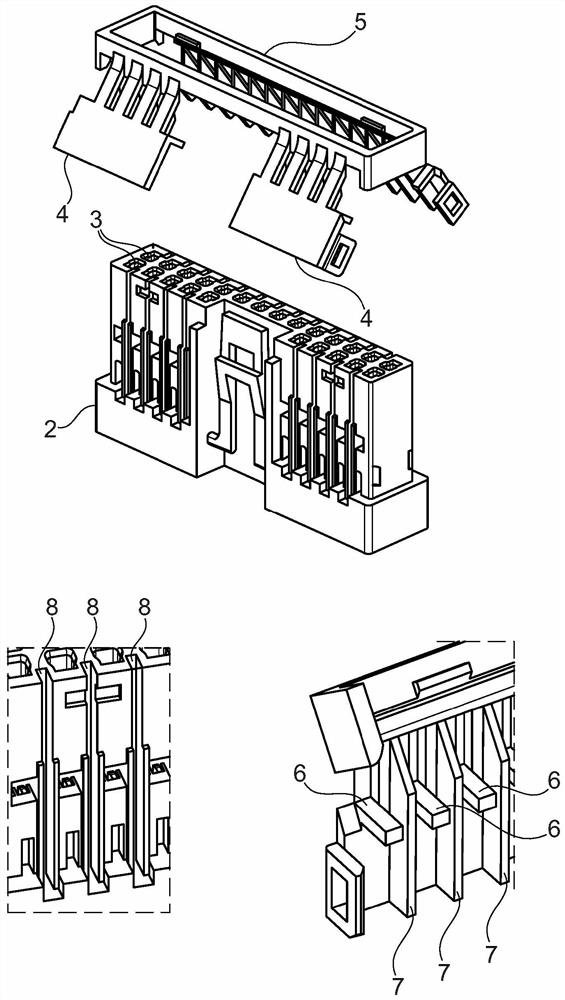

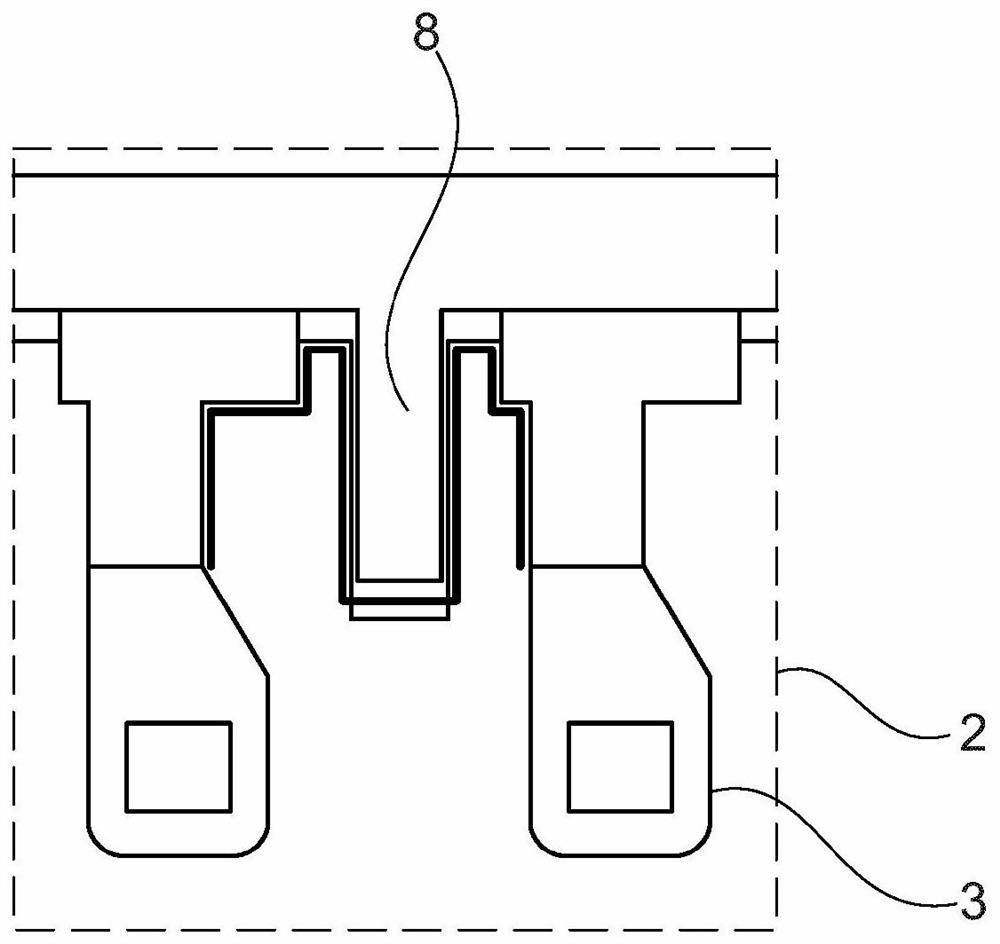

[0013] exist figure 1 A plug connector 1 with a contact carrier 2 is generally shown in detail. For example, two rows of five contact chambers 3 and one row of four contact chambers 3 are provided in the contact carrier 2 . The number of contact cavities and rows is not limited and can be single row, double row or even multiple rows, wherein the number of contact cavities 3 can also be selected according to the field of application of the plug connector 1 .

[0014] according to figure 1 The plug connector 1 also has at least one locking lug 4 , here a total of four locking lugs 4 . These locking pressure plates 4 can be directly arranged on the contact bracket 2 (in figure 1 not shown). The embodiment shown is as follows: The plug-in connector 1 comprises a frame 5 , from which the four locking tabs 4 extend and protrude slightly with their end regions from the contact carrier 2 . The frame 5 is arranged on the upper end of the contact carrier 2, which forms the plug-in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com