Cable connector including cable holder, and method of manufacturing cable connector

A technology for cable connectors and manufacturing methods, which is applied to the manufacture of contact boxes/bases, conductive connections, components of connecting devices, etc., and can solve the problems of cumbersomeness, enlargement, and easy fall off of cable holders, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

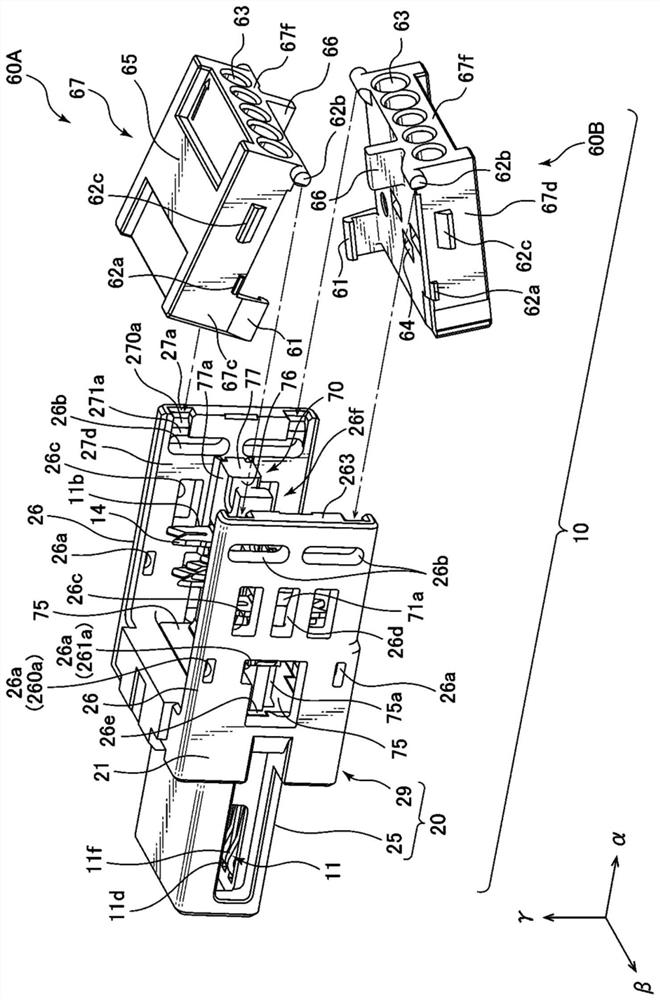

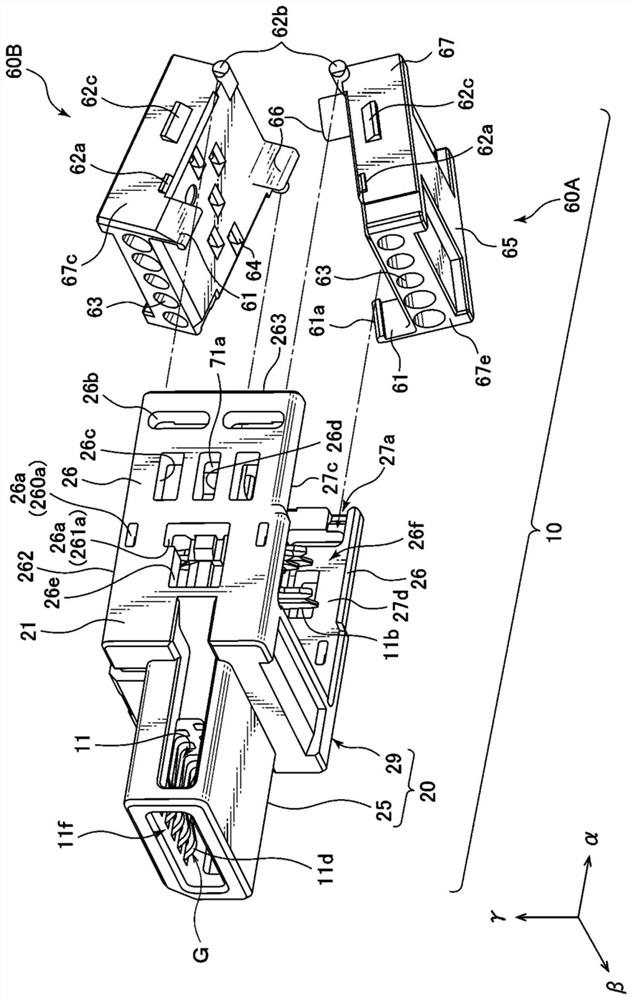

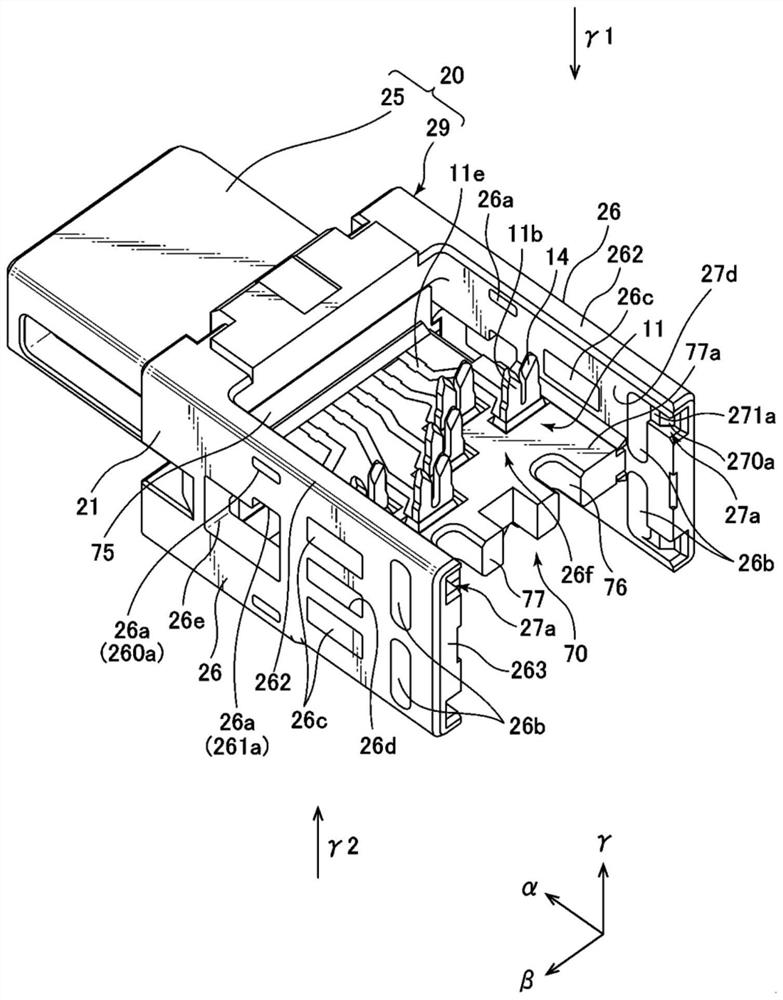

[0052] Hereinafter, a cable connector according to a preferred embodiment of the present invention and an electrical connector device including the cable connector will be described with reference to the drawings. Here, although only the preferred embodiment of this invention was shown, it goes without saying that this embodiment does not limit this invention. For example, in this embodiment, a twisted-pair cable is used, but as will be clear from the following description, it is not limited to a twisted-pair cable, and cables such as a single cable and twisted-wire cable can also be used, for example.

[0053] The present invention is Figure 21 The structures of the components in the conventional cable connector 10 shown in fig. Hereinafter, the structure of these components will be described. Items that are not particularly described are considered to be the same as those in Patent Document 1, but it is of course not intended to be limited to the structure disclosed in Pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com