Positive electrode active material for lithium ion secondary battery, method for manufacturing positive electrode active material for lithium ion secondary battery, and lithium ion secondary battery

A positive electrode active material and secondary battery technology, applied in the direction of active material electrodes, electrode manufacturing, secondary batteries, etc., can solve the problem of thermal stability reduction and achieve the effect of inhibiting oxygen release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

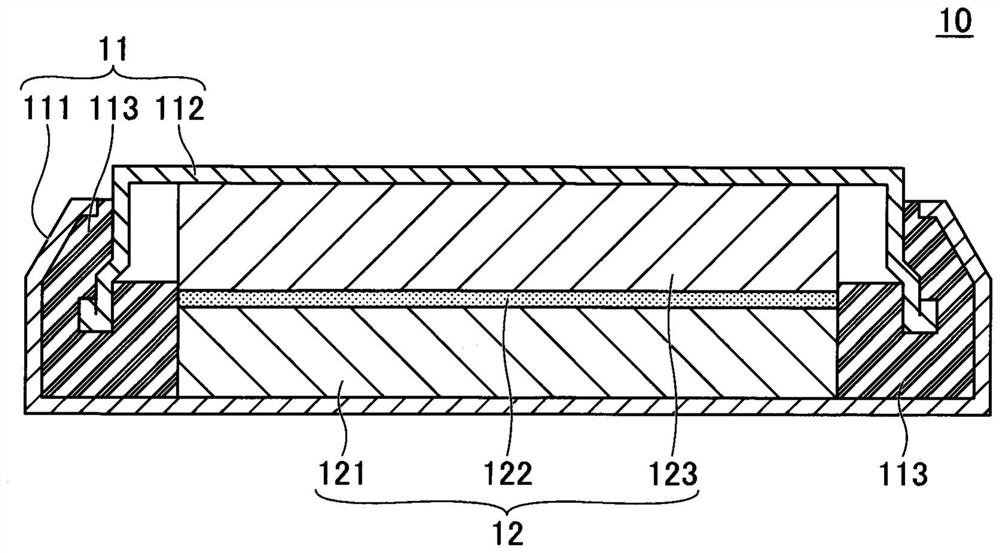

Image

Examples

Embodiment 1

[0154] (1) Preparation of positive electrode active material

[0155] The general formula with Ni as the main component: Ni 0.90 co 0.07 Al 0.03 (OH) 2 The metal composite hydroxide shown was heat-treated at 400° C. for 5 hours (first heat treatment step) and then at 700° C. for 5 hours (second heat treatment step) in air (oxygen concentration: 21% by volume) airflow. Thus, as a heat-treated metal complex compound, the general formula: Ni 0.90 co 0.07 Al 0.03 The metal composite oxide represented by O.

[0156] Next, Li / Me, which is the ratio of the number of atoms of lithium (Li) to the number of atoms of metals other than lithium (Me) in the resulting lithium mixture, was set to 1.01 for the metal composite oxide and lithium hydroxide obtained in the heat treatment step. The method was weighed and mixed sufficiently to obtain a lithium mixture (mixing process).

[0157] For mixing, a vibrating mixer device (Turbula Type T2C manufactured by Willy A. Bachofen (WAB)) wa...

Embodiment 2

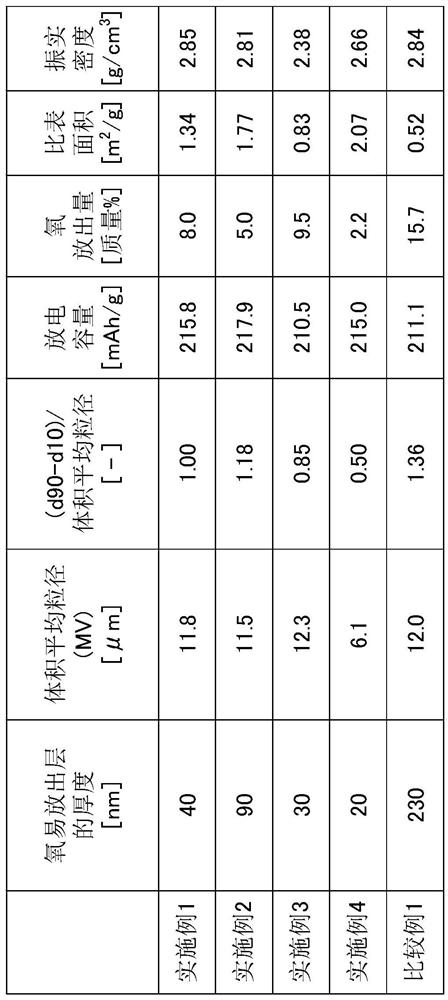

[0189] In the crushing process, the particle size distribution is adjusted so that [(d90-d10) / volume average particle diameter] becomes 1.18, except that, the same operation as in Example 1 is carried out to obtain a positive electrode active material and a secondary battery, and carry out its evaluation. The results are shown in Table 1.

Embodiment 3

[0191] In the crushing process, the particle size distribution is adjusted so that [(d90-d10) / volume average particle diameter] becomes 0.85, except that, the same operation as in Example 1 is carried out to obtain a positive electrode active material and a secondary battery, and carry out its evaluation. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com