Hand saw

A technology of hand saws and saw blades, which is applied in pad saws, saw blades, cross-cut saws, etc., which can solve the problems of enlarged saw teeth, easy hooking of saws, and increased distance between saw blades, so as to achieve smooth sawing start and smooth sawing Good effect in operation and cutting operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] A hand saw according to an embodiment of the present invention will be described below with reference to the drawings.

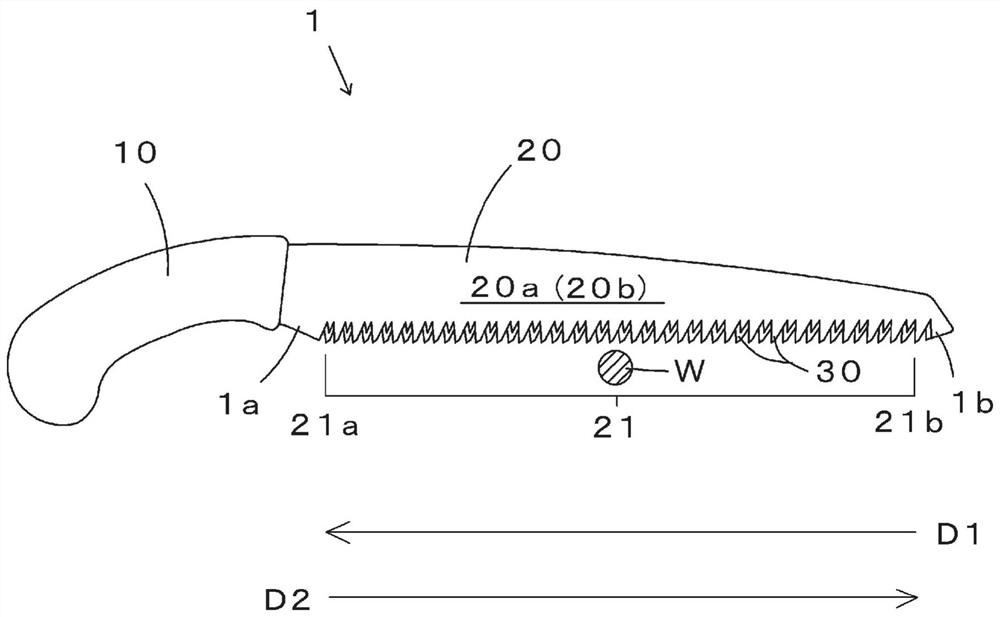

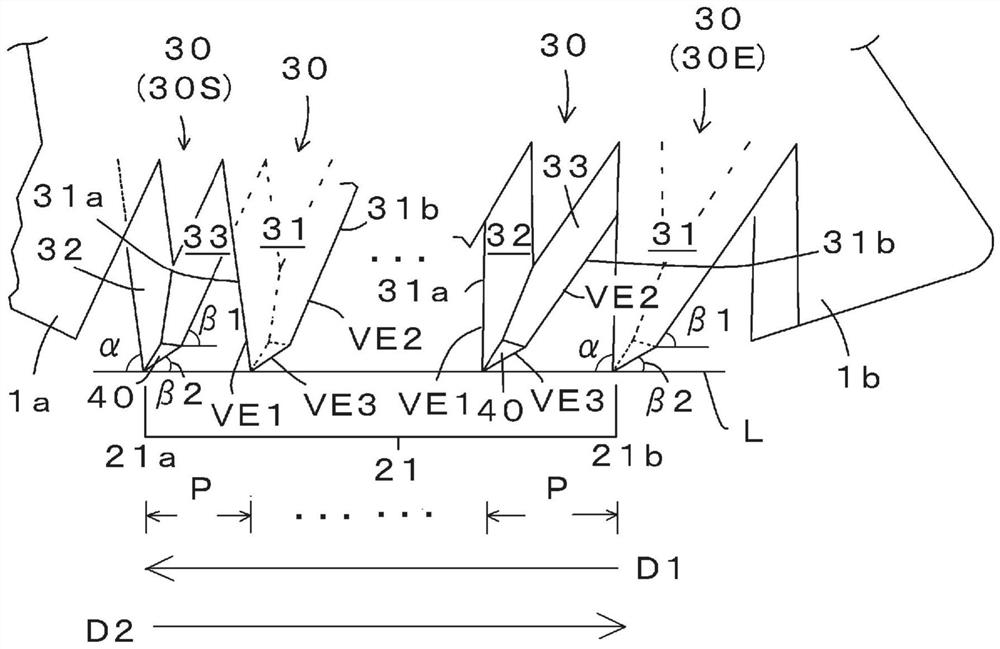

[0051] First, refer to figure 1 , The hand saw 1 as one of the embodiments of the present invention is equipped with a handle portion 10 and a saw body 20 . A plurality of saw teeth 30 are provided on the blade span portion 21 of the saw body 20 .

[0052] However, the hand saw 1 shown in the figure is not shown as a folding saw, but it can also be a folding saw. In addition, the hand saw 1 shown in the figure is a single-edged saw with a saw blade span portion 21 equipped with saw teeth 30 only on one side of the saw body 20, but it is not limited thereto, and may also be provided on the saw body 20. A double-edged saw with blade spans 21 on both sides.

[0053] The hand saw 1 according to the embodiment of the present invention includes a pull saw and a push saw as a single-handed saw and a saw configured as a pull saw.

[0054] The pull saw is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com