A kind of water-based ink filtration system and filtration method

A technology of water-based ink and filtration system, which is applied in the field of water-based ink filtration system and water-based ink filtration, can solve problems such as high cost, influence on printing processing, and clogging of filter elements, and achieve reduction in use efficiency, improvement of stability, and reduction of use cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

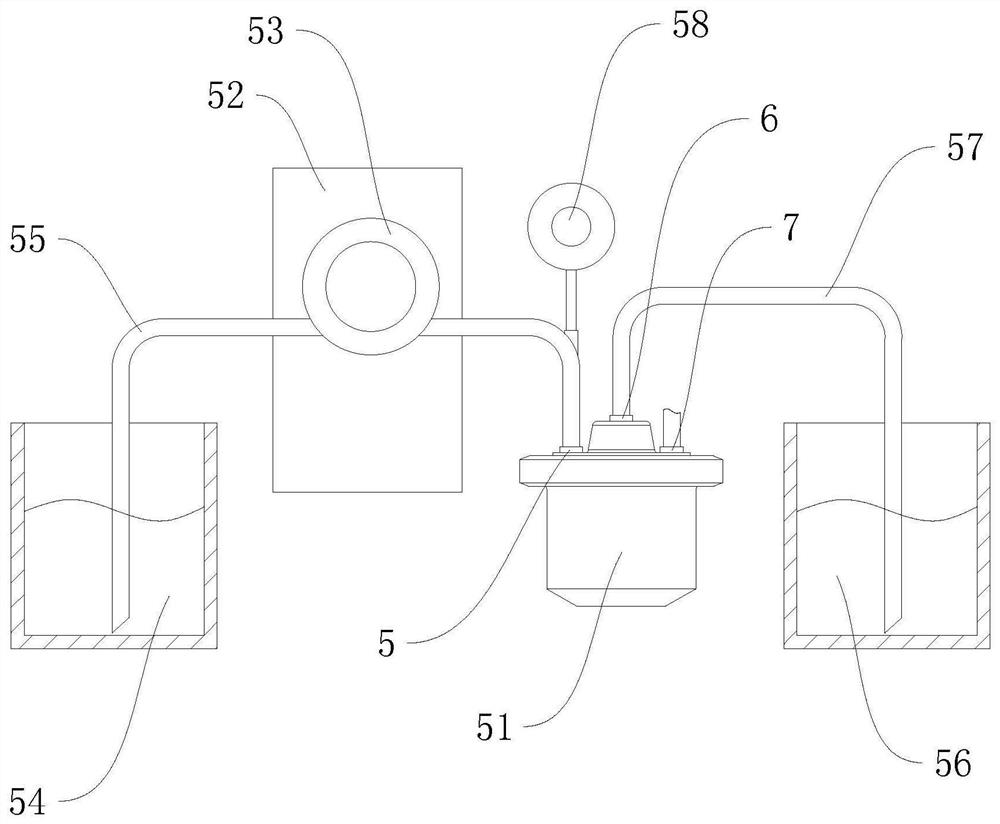

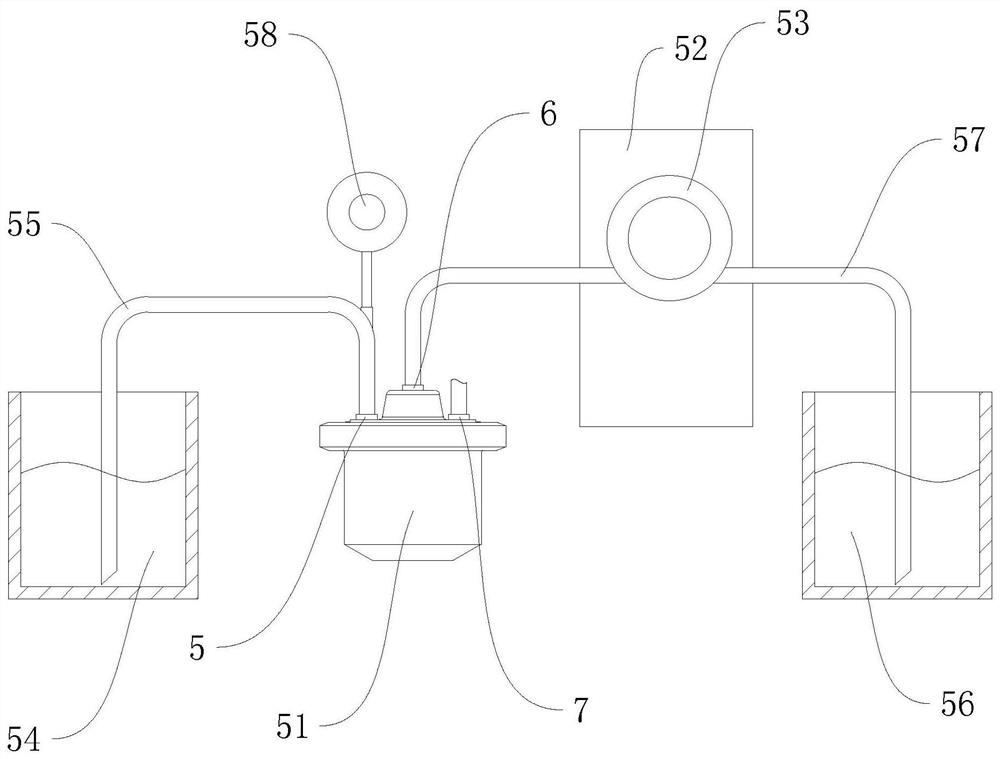

[0031] This embodiment discloses a water-based ink filtration system, refer to figure 1 and figure 2 As shown, including filter 51, peristaltic pump 52, pressure gauge 58, feed pipe 55, discharge pipe 57, ink tank one 54 and ink tank two 56, etc.; wherein the filter 51 is a capsule filter 51, the filter The filter 51 includes a filter bag 4 and a filter element 8 in the filter bag 4. A matching filter element 8 is installed in the filter bag 4, and a filter element 8 with an absolute accuracy of 0.45u is selected;

[0032] The filter bag 4 is provided with a liquid inlet 5, a liquid outlet 6 and an exhaust port 7. The liquid inlet 5 is connected to the ink tank 1 54 through the feeding pipe 55, and the liquid outlet 6 is connected to the ink through the discharging pipe 57. The second tank 56 is connected to an appropriate exhaust pipeline at the exhaust port 7; the test end of the pressure gauge 58 extends into the liquid inlet 5 of the filter bag 4, and can detect the pres...

Embodiment 2

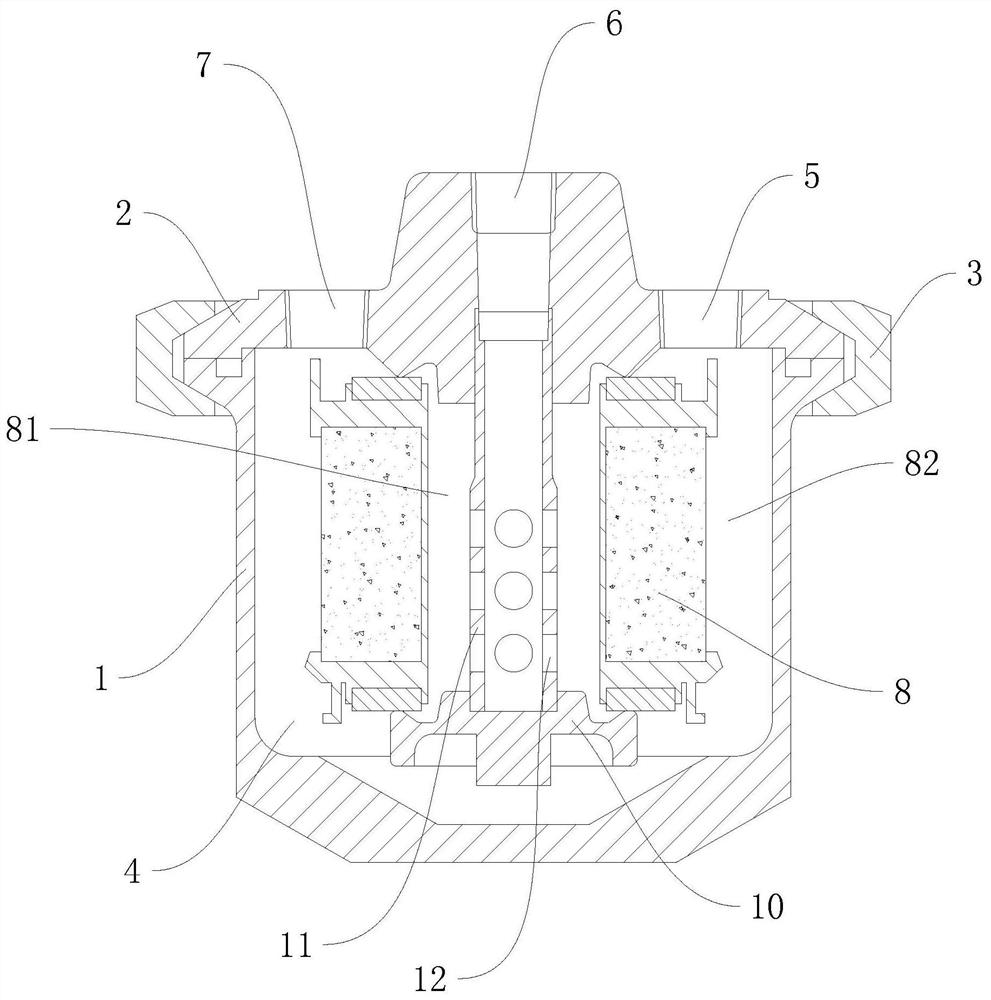

[0046] This embodiment discloses a water-based ink filtration system. On the basis of Embodiment 1, the filter 51 is further improved to improve the filtration stability of the filter 51; image 3 As shown, the filter bag 4 of the filter 51 includes a base 1, a top cover 2 and a snap ring 3. The interior of the base 1 is hollow and the top is open, and the top cover 2 is covered with the opening of the base 1, and after the cover is closed, it is in the shape of a bag, And sealed by a seal, and a convex ring is formed on the outer circumference of the base 1 and the top cover 2, and the outer circumference is buckled and assembled by the buckle ring 3;

[0047] A liquid outlet 6 is provided in the middle of the top cover 2, and a liquid inlet 5 and an exhaust port 7 are respectively provided on both sides. The inner side of the liquid outlet 6 is connected with a material guide pipe 11, and the side of the material guide pipe is provided with a material guide port 1. 12. The l...

Embodiment 3

[0049] This embodiment discloses a water-washing ink filtration system. On the basis of Embodiment 2, refer to Figure 4 and Figure 5 , the filter 51 in the above-mentioned embodiment is further improved;

[0050] A support cylinder 9 is fixed in the middle of the bottom of the base 1 , the support cover 10 at the lower part of the filter element 8 is threadedly connected to the upper end of the support cylinder 9 , and the interior of the material guide pipe 1 11 is slidably connected with the material guide pipe 2 13 , and the material guide pipe 2 13 There is a second material guide port 14 corresponding to the material guide port 1 12 on the outer periphery of the machine, and the relative position of the material guide port 1 12 and the material guide port 2 14 can be adjusted by sliding the material guide pipe 2 13, thereby regulating the material guide port 1 12 open or close;

[0051] The lower end of the second feeding tube 13 extends downward, penetrates the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com