Breathable shoe sole

A technology of breathable shoes and airbags, which is applied in the field of footwear manufacturing, can solve the problems of affecting the control and durability of shoe elastic strength, unsatisfactory ventilation effect, and affecting the comfort of feet, etc., and achieves low production cost, remarkable permeability effect, The effect of flexibility and adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

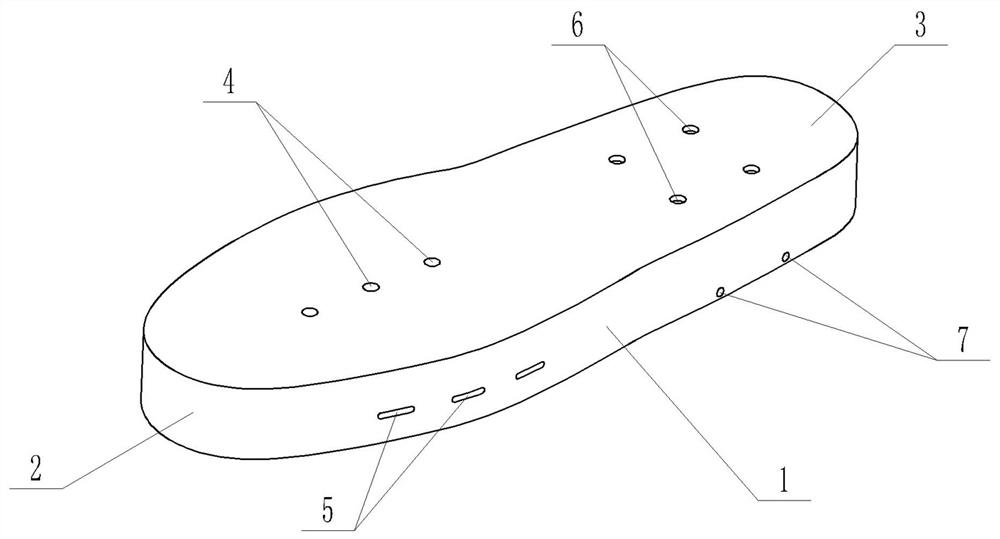

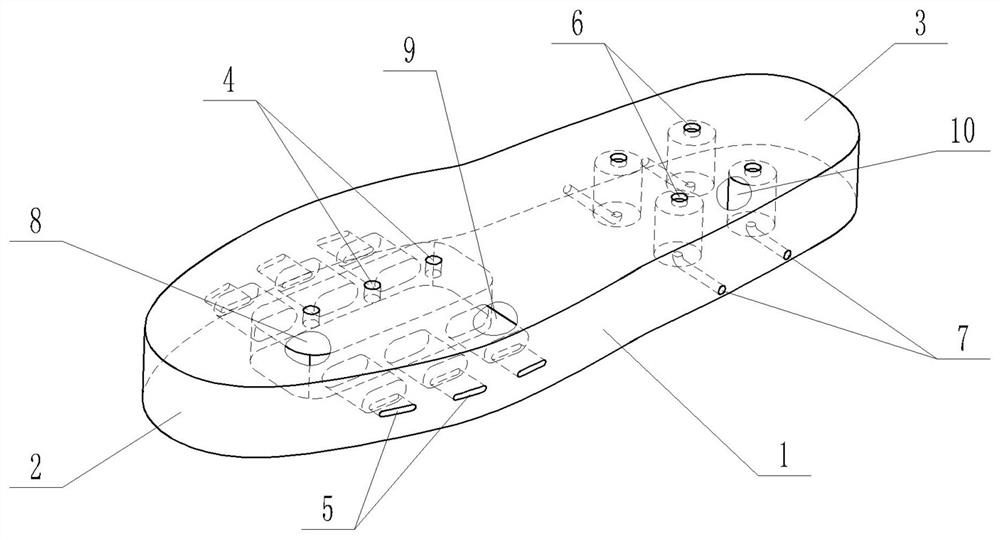

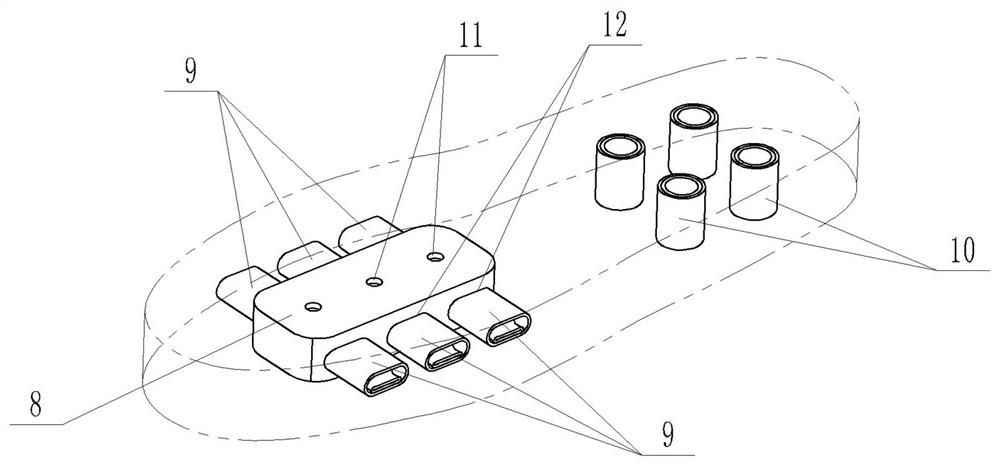

[0032] according to Figure 1-16 The specific structure of the present invention will be described in detail. The breathable sole includes a breathable shoe midsole 30, the upper side of the breathable shoe midsole 30 is provided with a breathable shoe upper bottom 32 with good permeability for covering the air inlet 4 at the front of the sole and the air inlet 6 at the heel of the foot; The lower side of the breathable shoe midsole 30 is provided with a wear-resistant shoe bottom 31 for contacting with the ground. The breathable midsole 30 is composed of the midsole main body 1 and the surrounding additives, and the filling part of the midsole main body 1 can be made of a material that is soft, elastic, and has a large compression space (for example: secondary foam PHYLON, PU, etc.). The interior of the forefoot end 2 of the midsole main body 1 is provided with a transitional airbag cavity 8, and several groups of air intake holes 4 at the front of the sole are provided o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com