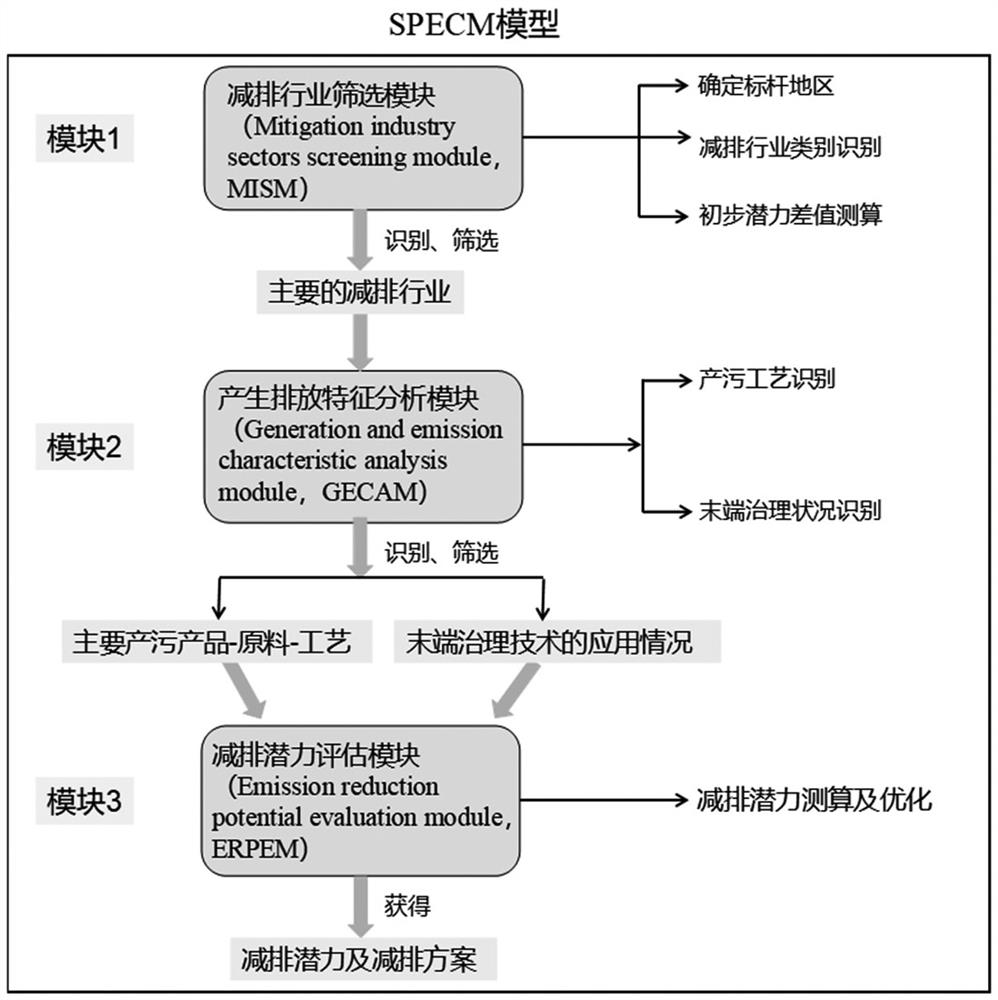

Industrial industry source-process-terminal whole process collaborative emission reduction potential assessment method

An industrial, whole-process technology, applied in the field of environmental management, can solve the problems of lack of systematic consideration, lack of precision and pertinence of measures, lack of research on the synergistic emission reduction effect of cleaner production and end-of-line treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] In this example, Shunde District, Foshan City, Guangdong Province is selected as the area to be evaluated, and the industry in this area is evaluated for the source-process-end process collaborative emission reduction potential, which specifically includes the following steps:

[0054] S1, Top-down Calculation of Emission Reduction Potential Difference Based on Scenario Analysis

[0055] S11, determine the benchmark area:

[0056] According to the industrial structure of Shunde District, Foshan City, Guangdong Province, Shenzhen City, which has a similar industrial structure to Shunde District but has a high level of clean production, is selected as a benchmark area.

[0057] S12, Identification of emission reduction industry categories:

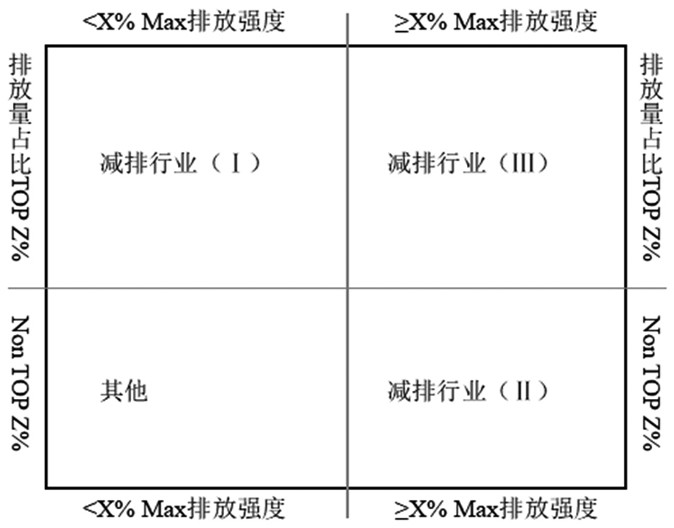

[0058] According to the two dimensions of emission proportion (X%=2%) and emission intensity (Z%=75%), the figure 2 The identification criteria shown classify the industrial sectors in the area to be evaluated into emission reducti...

Embodiment 2

[0108] In this example, Lanzhou City, Gansu Province is selected as the area to be evaluated, and the industry in this area is evaluated for the source-process-end process collaborative emission reduction potential, which specifically includes the following steps:

[0109] S1, Top-down Calculation of Emission Reduction Potential Difference Based on Scenario Analysis

[0110] S11, determine the benchmark area:

[0111] According to the industrial structure of Lanzhou City, Gansu Province, Gansu Province and Shenzhen City, which have a similar industrial structure to Lanzhou City but have a relatively high level of clean production, are selected as benchmark regions.

[0112] S12, Identification of emission reduction industry categories:

[0113] According to the two dimensions of emission proportion (X%=2%) and emission intensity (Z%=99%), the figure 2 The identification criteria shown classify the industrial sectors in the area to be evaluated into emission reduction indust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com