Laminating drum preshrinking method for avoiding clamping deformation of tread of VMI forming machine

A drum-fitting and pre-shrinking technology, applied in the field of tire manufacturing, can solve problems such as the inability to set the tightening distance of the clamping block, the sagging deformation of the tread component, and the impact on the quality of the tire, so as to solve the problem of the clamping deformation of the tread. , reduce the degree of clamping, improve the effect of comprehensive quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

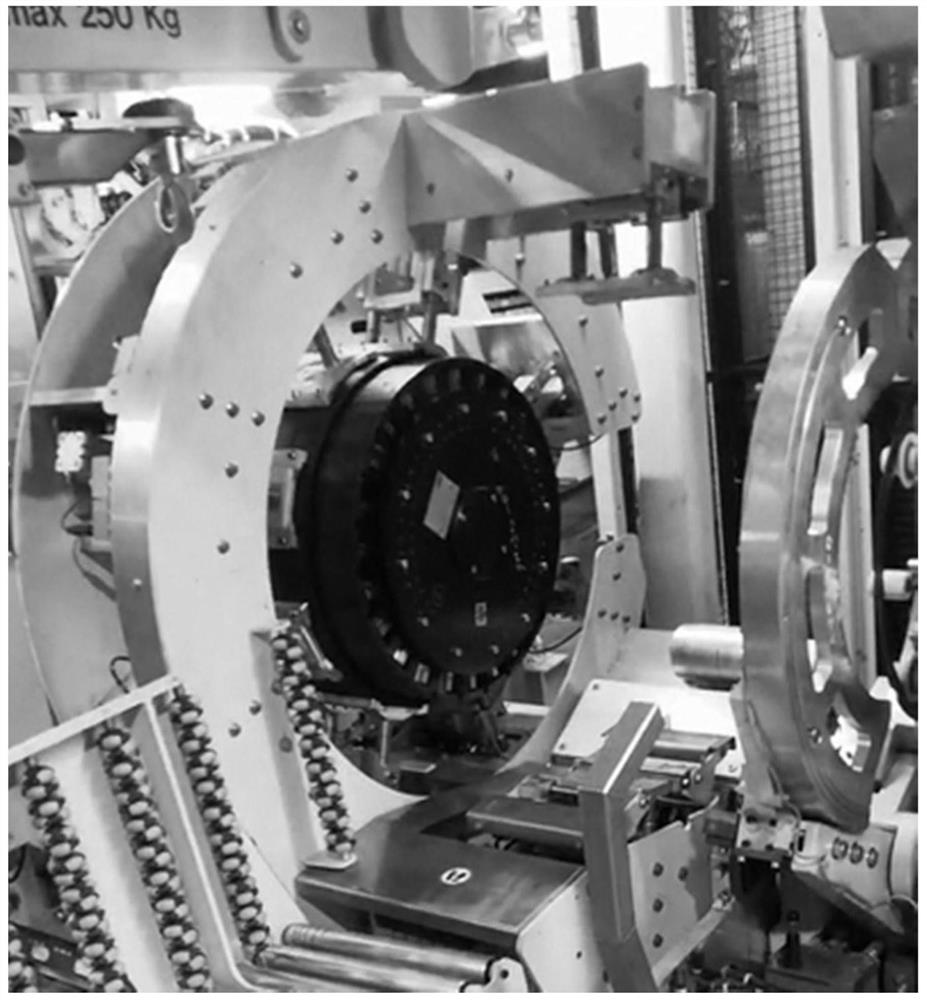

Image

Examples

Embodiment 1

[0020] A method of pre-shrinking the fitting drum to avoid the clamping deformation of the tread of the VMI molding machine. During the process of shrinking the clamping ring to prepare the tread for clamping, the fitting drum is pre-shrunk by a certain amount radially inward. In order to reduce the clamping degree of the clamping ring to the tread assembly;

[0021] Among them, the pre-shrinkage of the bonding drum has the following process:

[0022] (1) The clamping ring is ready to clamp the tread assembly;

[0023] (2) Pre-shrink the fitting drum;

[0024] (3) The clamping ring clamps the tread assembly, and the fitting drum shrinks to the end;

[0025] In addition, the specific operation for pre-shrinkage adjustment in the operation page of the bonding drum in the one-shot VMI molding machine is: after the belt drum is selected, the pre-shrinkage drum before the tread assembly is removed in the product parameter column Set the setting value to 0-10mm.

[0026] Under o...

Embodiment 2

[0029] This embodiment is basically the same as the first embodiment above, and its main difference is:

[0030] Under other identical conditions, the pre-shrinkage of the fit drum circumference is set to 5mm.

[0031] Test results: The tread components are normal; the comprehensive pass rate is 100% (100 pieces). 4-6mm

Embodiment 3

[0033] This embodiment is basically the same as the first embodiment above, and its main difference is:

[0034] Under the same other conditions, the pre-shrinkage of the fit drum circumference is set to 8mm.

[0035] Test results: The belt of the tread assembly is arched; the comprehensive pass rate is 98% (100 pieces).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com