Method for the production of a stator and stator produced according thereto

A manufacturing method and stator technology, applied in the manufacture of stator/rotor body, motor generator, magnetic circuit shape/style/structure, etc., can solve the problems of increasing the outer diameter of the motor, so as to improve the axial stiffness and fixation , the effect of reducing the risk of loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

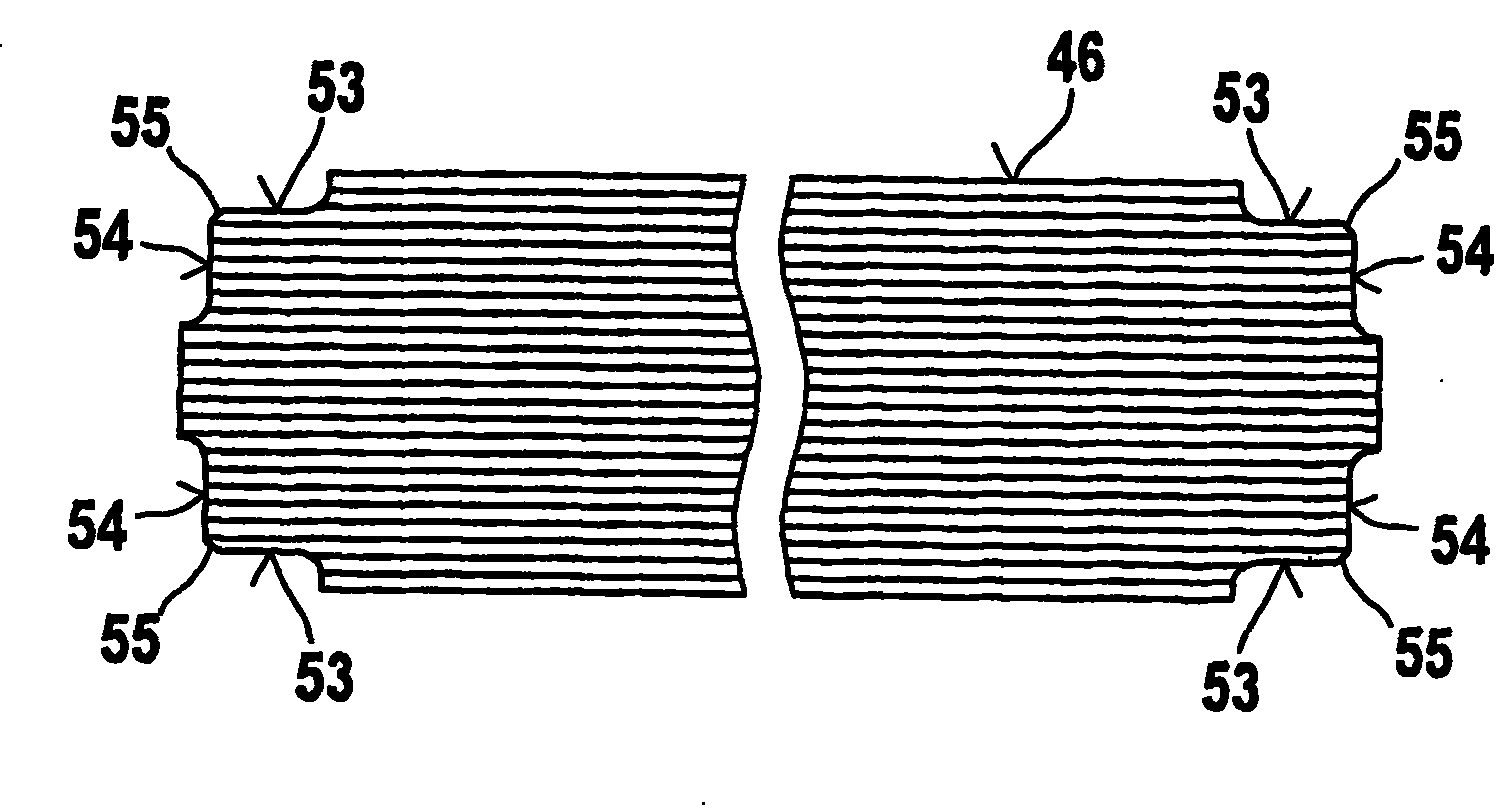

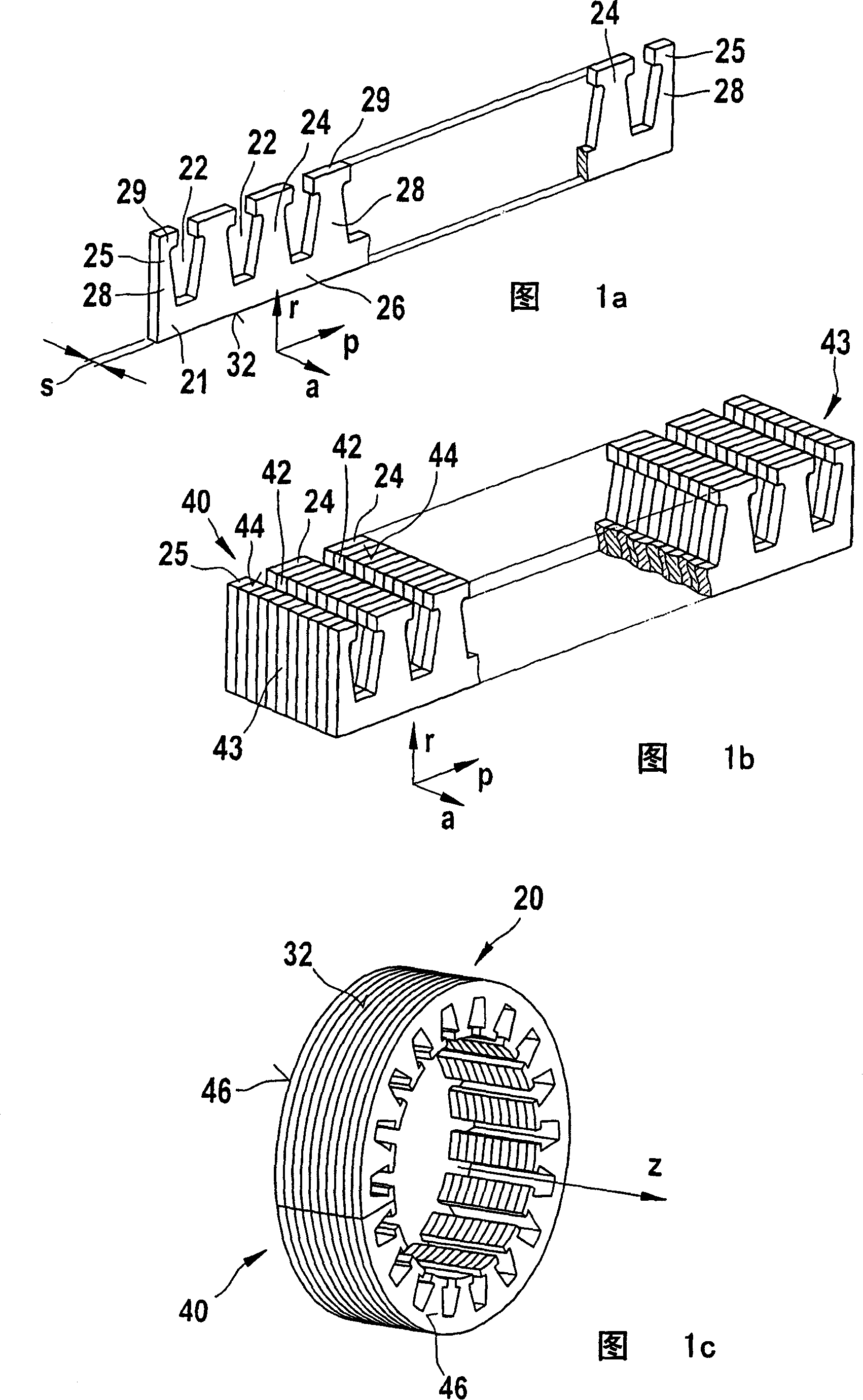

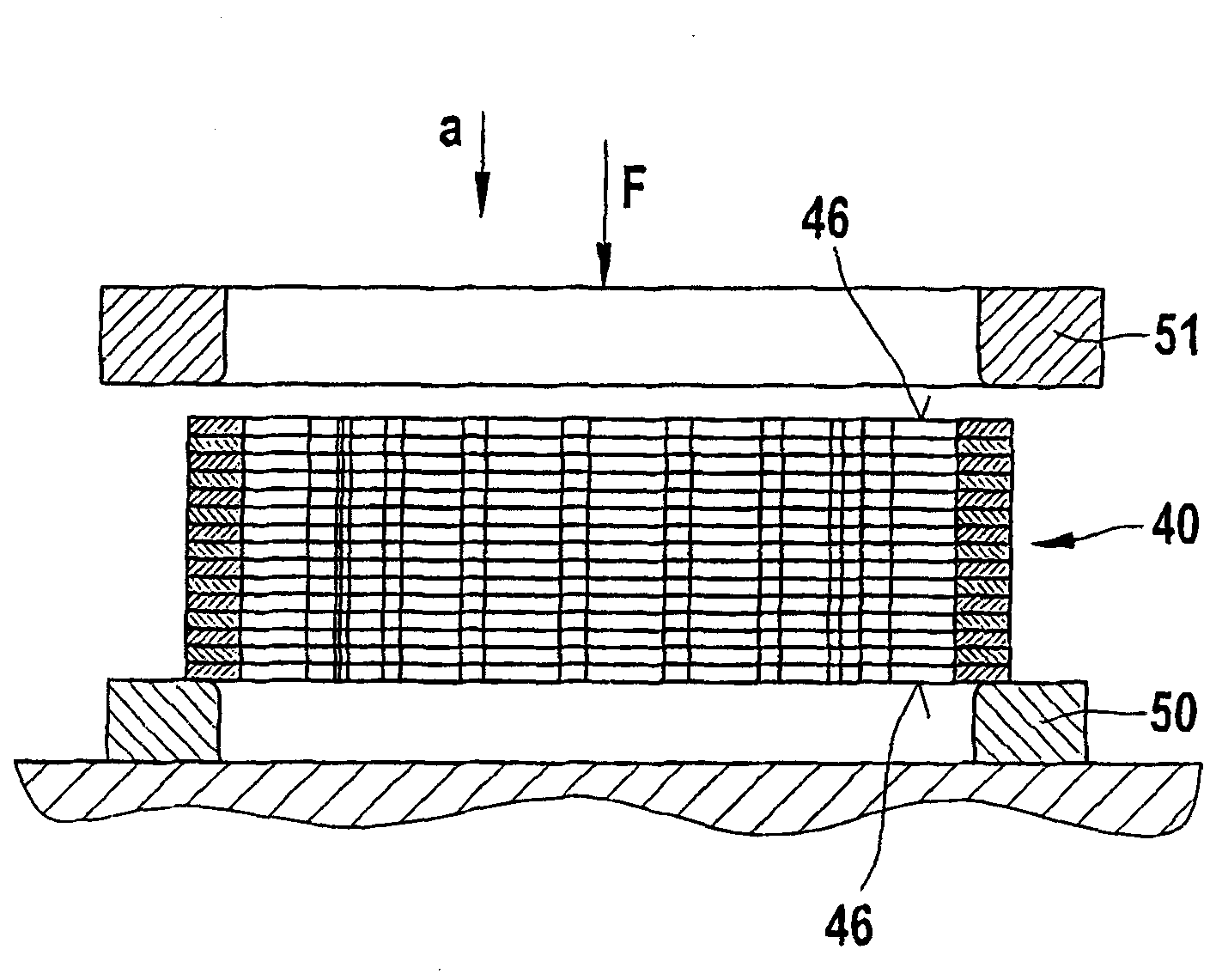

[0039] Figures 1a, 1b and 1c show the basic method of manufacturing a stator core 20 of an electrical machine manufactured according to the so-called lamination method. First, a substantially rectangular or cuboid-shaped strip 21 is provided, which has notches 22 . Both sides of these notches 22 are delimited by teeth 24 or half teeth 25 , respectively. The individual teeth 24 or half-tooths 25 are connected to each other via a yoke 26 . The yoke 26 extends substantially in the circumferential direction p and in the radial direction r, moreover it generally has a material thickness s which corresponds to the thickness of the lamination 21 . The yoke 26 has a yoke back 32 facing away from the tooth 24 or half-tooth 25 . The back face 32 of the yoke is oriented opposite to the direction r. The teeth 24 and the half-tooths 25 extend substantially in the radial direction r and in the circumferential direction p. The teeth 24 and half teeth 25 also have a material thickness s. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com