Fire-fighting equipment surface layer paint spraying equipment

A technology of spraying equipment and fire fighting equipment, applied in spray booths, coatings, spraying devices, etc., can solve the problems of low work efficiency and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

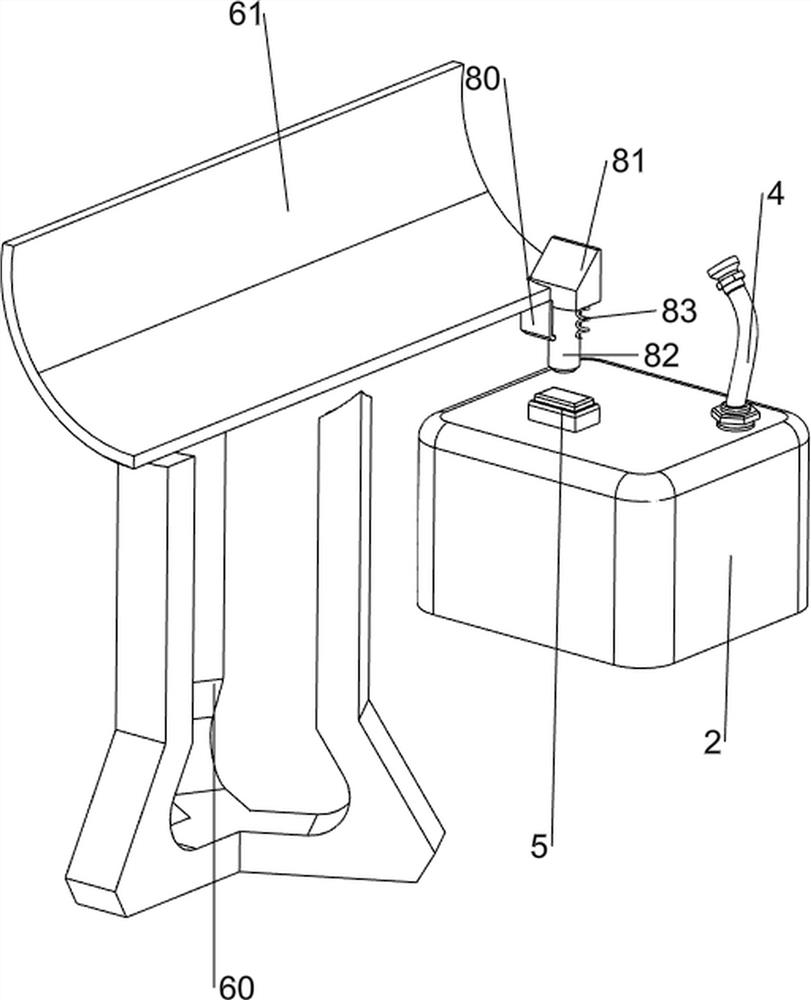

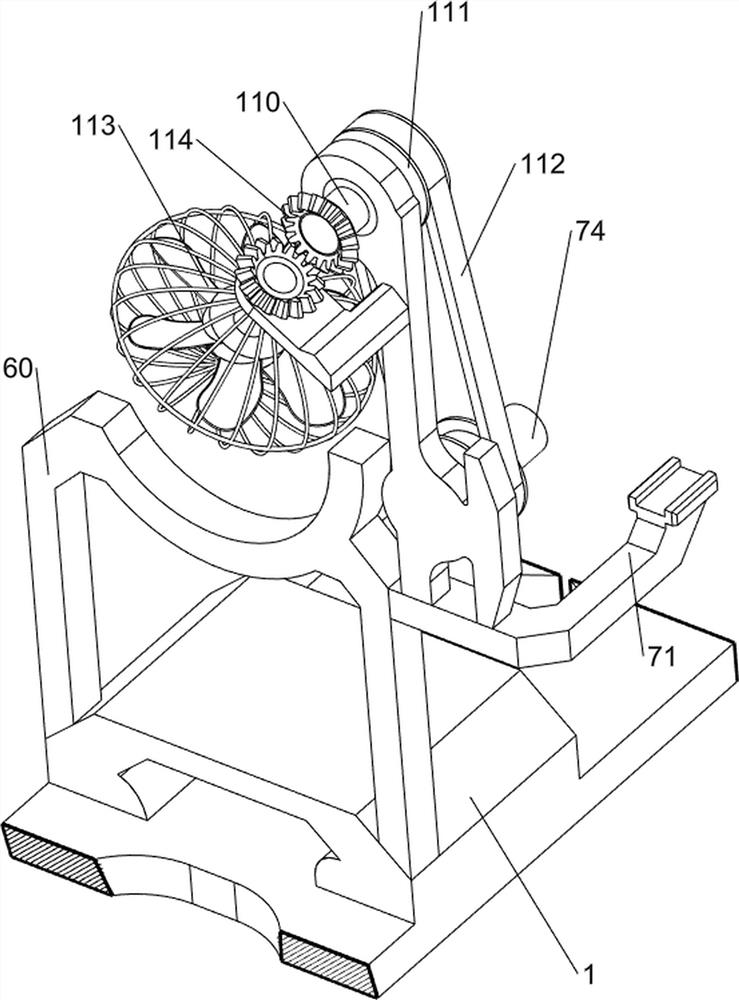

[0026] A kind of fire-fighting equipment surface layer painting equipment, such as Figure 1-Figure 4 As shown, it includes a shell 1, a paint box 2, a paint spray block 3, a hose 4, a switch 5, a push mechanism 6, a rotating mechanism 7 and a control mechanism 8, and the right part of the upper side of the shell 1 is connected with a paint box 2. The upper front part of the paint box 2 is connected with a hose 4, the upper side of the hose 4 is rotatably provided with a paint spraying block 3, the upper side of the paint box 2 is connected with a switch 5, and the upper right part of the casing 1 is provided with a push mechanism 6, and the casing The middle part of the upper side is provided with a rotating mechanism 7, and the inner lower side of the pushing mechanism 6 is connected with a control mechanism 8.

[0027] When the device needs to be used, the user can place the fire-fighting equipment in the push mechanism 6, start the push mechanism 6, and the push mechanism ...

Embodiment 2

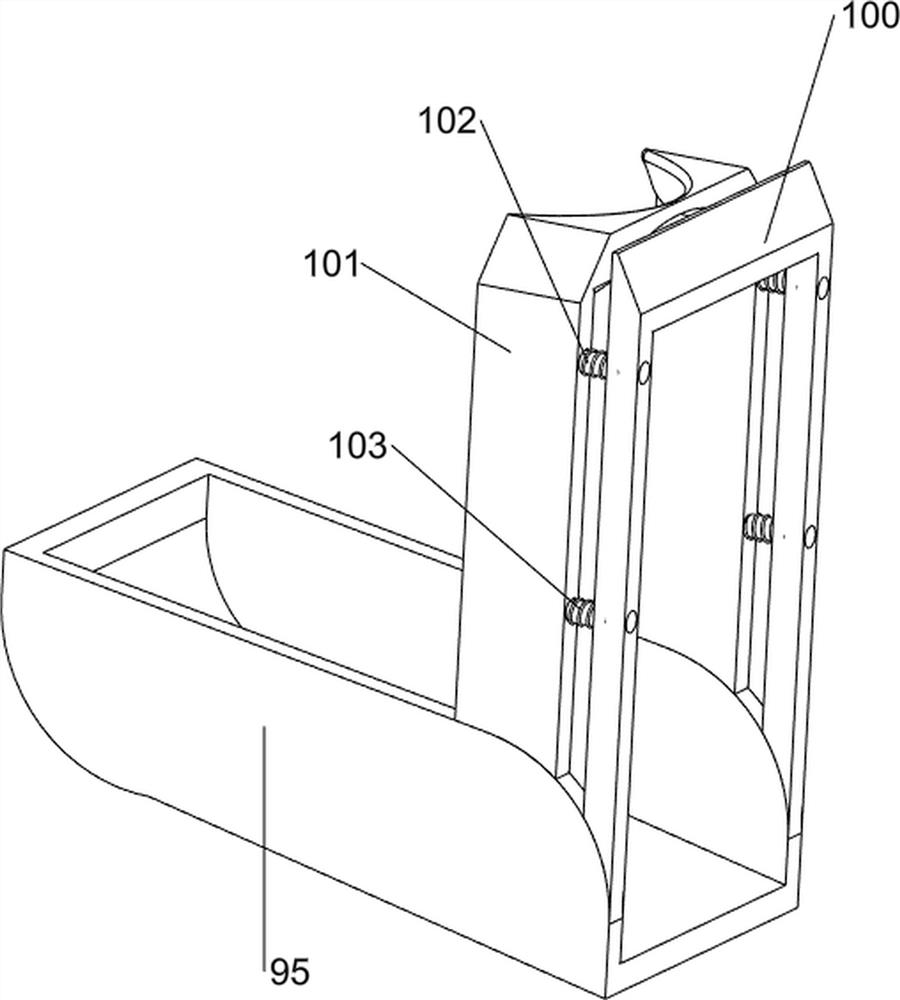

[0035] On the basis of Example 1, such as Figure 5-Figure 7 As shown, a feeding mechanism 9 is also included, and the feeding mechanism 9 includes a third support block 90, a feeding plate 91, a third rotating shaft 92, a second one-way gear 93, a second rack 94, and a support plate 95 And the toggle block 96, the left side of the upper part of the shell 1 is provided with a third support block 90, the upper side of the third support block 90 is connected with a feeding plate 91, the right side of the third support block 90 is provided with a support plate 95, and the support plate 95 Rotationally connected with a third rotating shaft 92, the third rotating shaft 92 is connected with a toggle block 96, the lower side of the third rotating shaft 92 is connected with a second one-way gear 93, and the left side of the first connecting block 63 is connected with a second one-way gear. The rack 94 , the second rack 94 cooperates with the second one-way gear 93 .

[0036] When the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com