Grounding device of high-capacity power transformer

A technology of power transformers and grounding devices, which is applied in the field of transformers, can solve the problems of time-consuming and laborious, inconvenient portability of welding machines, and the need for on-site power connection, etc., and achieves a strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

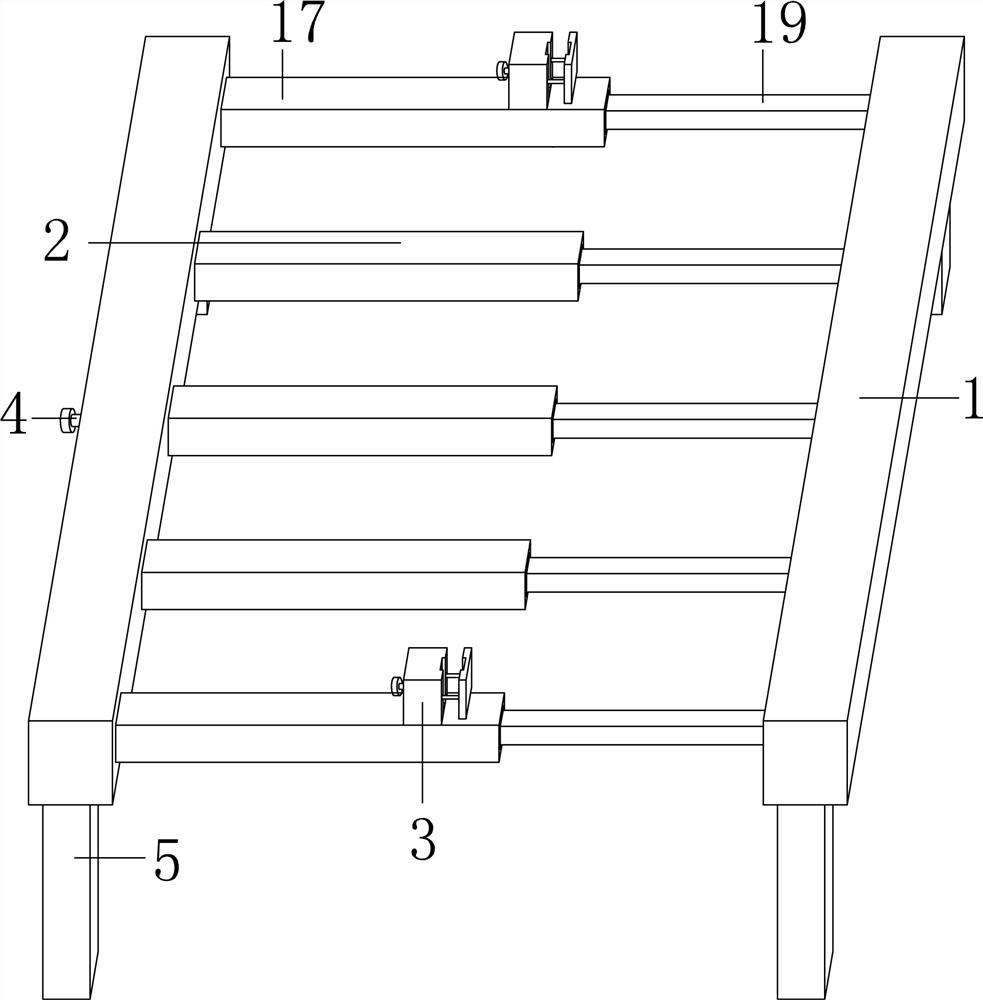

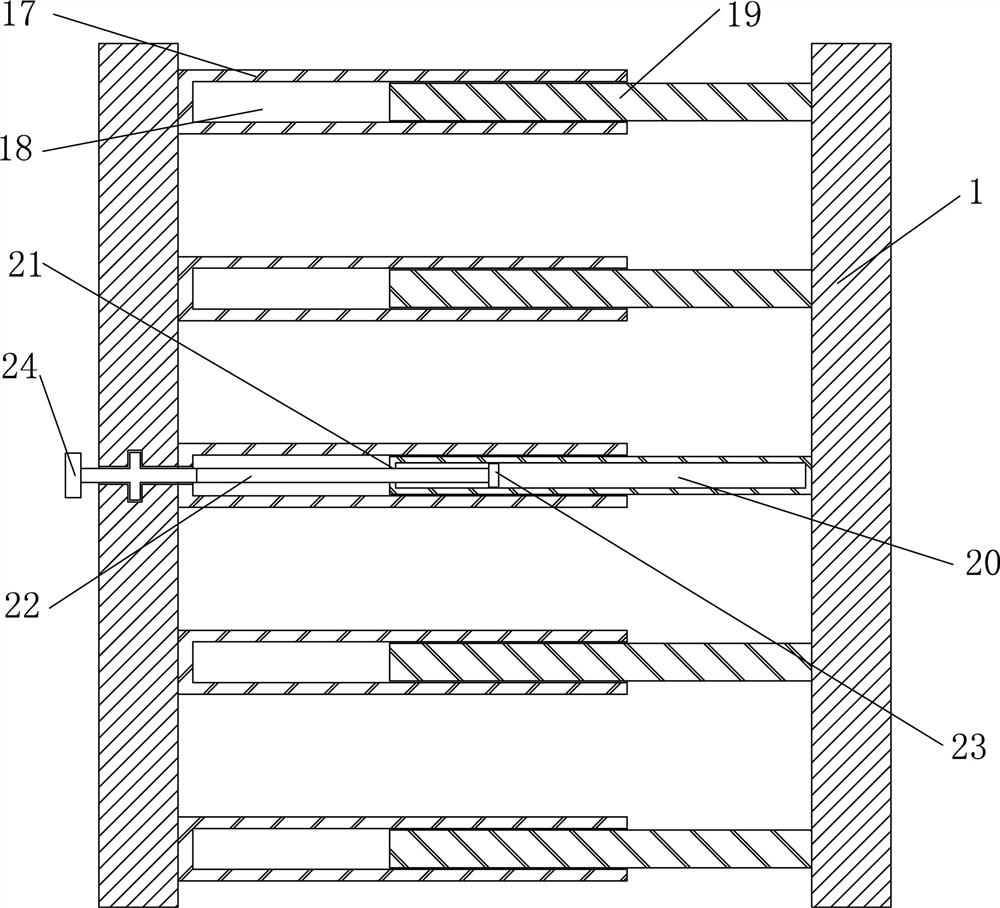

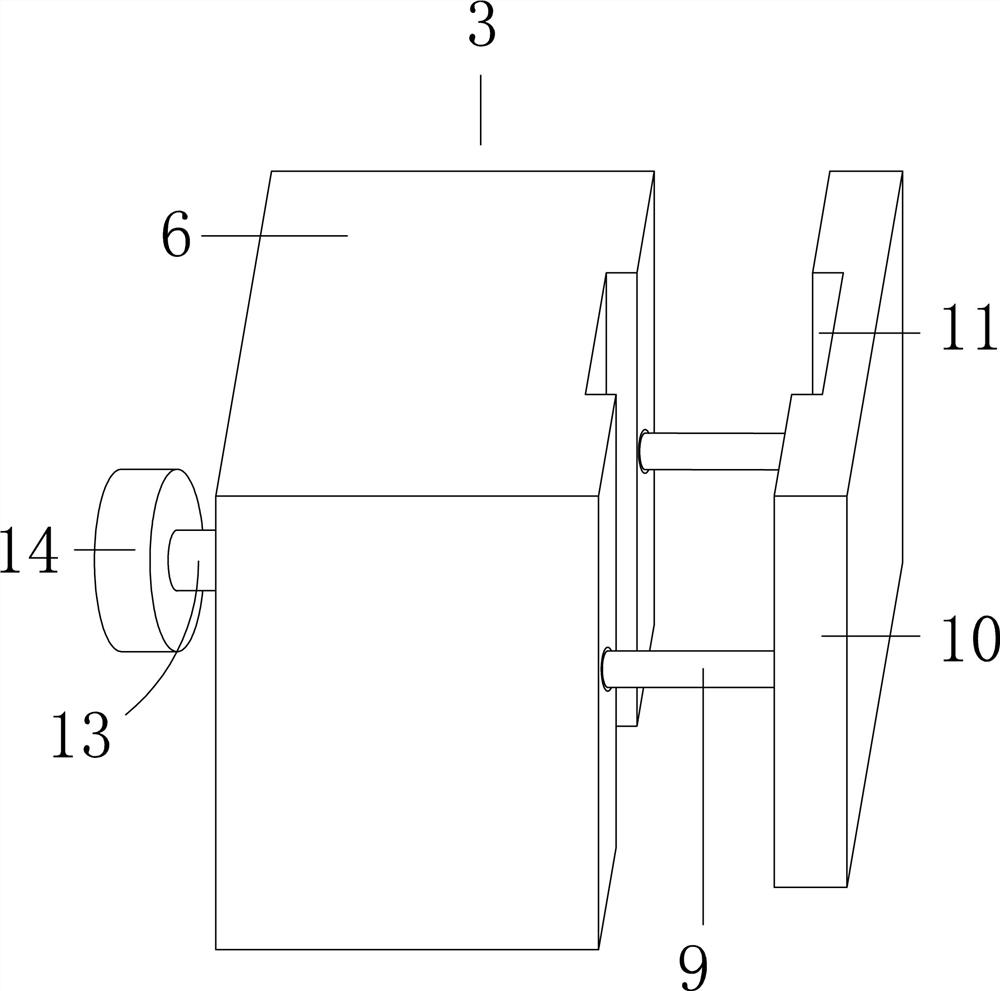

[0024] Such as figure 1 As shown, a grounding device for a large-capacity power transformer includes a mounting rod 1 , an expansion member 2 , a clamping device 3 , and a contraction member 4 . Wherein, the mounting rods 1 are arranged left and right, and both ends of the lower end surface of each mounting rod 1 are fixedly connected with outriggers 5 . After the two installation rods 1 are placed in the pre-buried pit, by inserting the legs 5 into the soil, the two installation rods 1 can be prevented from moving in the pre-buried pit. The telescopic parts 2 are arranged in parallel between the two installation rods 1 in multiple groups, and the two installation rods 1 are connected through the telescopic parts 2 . Adjusting the length of the telescopic member 2 enables the two installation rods 1 to be freely combined and installed according to the size of the grounding grid required by the construction pit and the supporting substation equipment. The contraction part 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com