Jacquard automatic edge separation screen cloth and manufacturing method thereof

A production method and automatic technology, applied in textiles and papermaking, knitting, warp knitting, etc., can solve problems such as unfavorable energy saving and environmental protection, impact on quality, and uneven cutting, so as to eliminate hidden dangers in production safety, complete and stable physical properties, and save energy. The effect of electricity usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

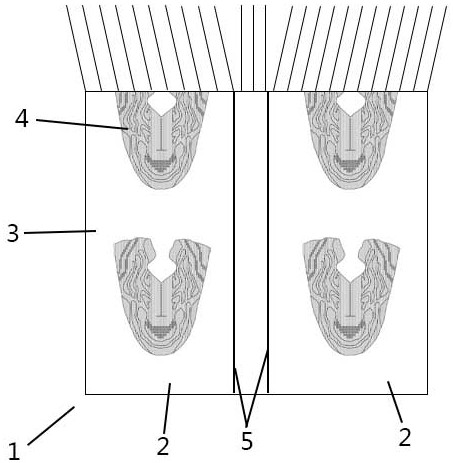

[0043] refer to figure 1 and image 3 , the present invention provides a kind of Jacquard automatic edge-separating mesh, and the Jacquard automatic edge-separating mesh of this embodiment is integrally woven by a Jacquard warp knitting machine, which includes a mesh body 1, and the mesh body 1 is composed of at least It is composed of two edge-separating cloths 2, and the edge-separating cloth 2 includes a floor comb layer 3, a jacquard layer 4 and an edge-sealing shared layer 5.

[0044] S1. Bar setting: the Jacquard warp knitting machine for knitting has 4 bars, and the 4 bars are set as the first ground bar (hereinafter referred to as: GB1) and the second bar from the front needle bed to the rear needle bed. The card bar (hereinafter referred to as: JK1-1), the second Jacquard bar (hereinafter: GB1-2), the fourth ground bar (hereinafter: GB4).

[0045] S2. Bar threading: JK1-1 and JK1-2 are threaded in the way of 1 thread and 1 empty, that is, after each thread is thread...

Embodiment 2

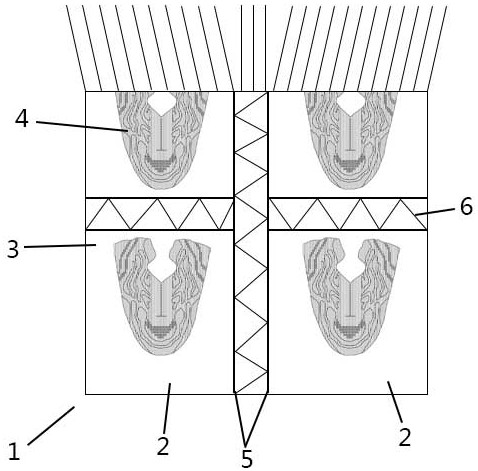

[0052] refer to figure 1 and Figure 4 , on the basis of embodiment 1, a kind of jacquard automatic edge-separating mesh cloth of the present invention can also:

[0053] S1. Bar setting: the Jacquard warp knitting machine for knitting has 7 bars, and the 7 bars are set as the first ground bar (hereinafter referred to as: GB1), the second Jia card bar from the front needle bed to the rear needle bed in sequence. Jacquard bar (hereinafter referred to as: JK1-1), the third Jacquard bar (hereinafter referred to as: JK1-2), the fourth Jacquard bar (hereinafter referred to as: JK2-1), the fifth Jacquard bar (hereinafter Name: JK2-2), the sixth ground comb (hereinafter referred to as: GB6), and the seventh ground comb (hereinafter: GB7).

[0054] S2. Bar threading: JK1-1, JK1-2, JK2-1, and JK2-2 are all threaded in the way of 1 thread and 1 empty, that is, after each thread is threaded, a position is vacated for continuous threading Yarn; GB1, GB6, GB7 are all threaded in the way...

Embodiment 3

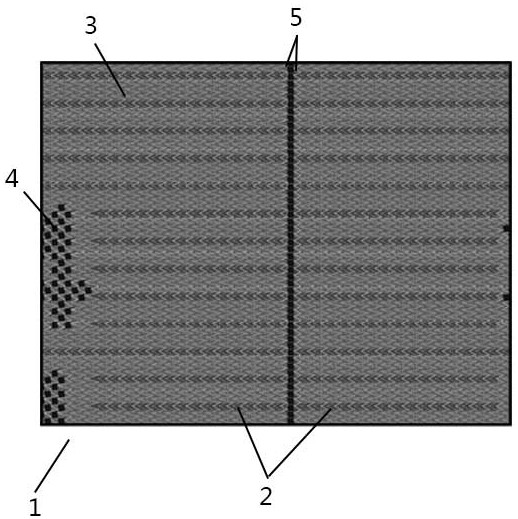

[0064] refer to figure 1 and Figure 5 , on the basis of embodiment 1, a kind of jacquard automatic edge-separating mesh cloth provided by the present invention can also:

[0065] S1. Bar setting: the Jacquard warp knitting machine for knitting has 8 bars, and the 8 bars are sequentially set as the first bar (hereinafter referred to as: GB1) and the second bar from the front needle bed to the rear needle bed. Jacquard bar (hereinafter referred to as: GB2), the third Jacquard bar (hereinafter referred to as: JK1-1), the fourth Jacquard bar (hereinafter referred to as: JK1-2), the fifth Jacquard bar (hereinafter: JK2-1), the sixth Jacquard bar (hereinafter referred to as: JK2-2), the seventh ground bar (hereinafter: GB7), and the eighth ground bar (hereinafter: GB8).

[0066] S2. Bar threading: JK1-1, JK1-2, JK2-1, and JK2-2 are all threaded in the way of 1 thread and 1 empty, that is, after each thread is threaded, a position is vacated for continuous threading Yarn; GB1, GB...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com