Method for controlling suction pressure of a vapour compression system

A vapor compression, pressure technology, used in compressors with multiple evaporators, compressors, compressors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

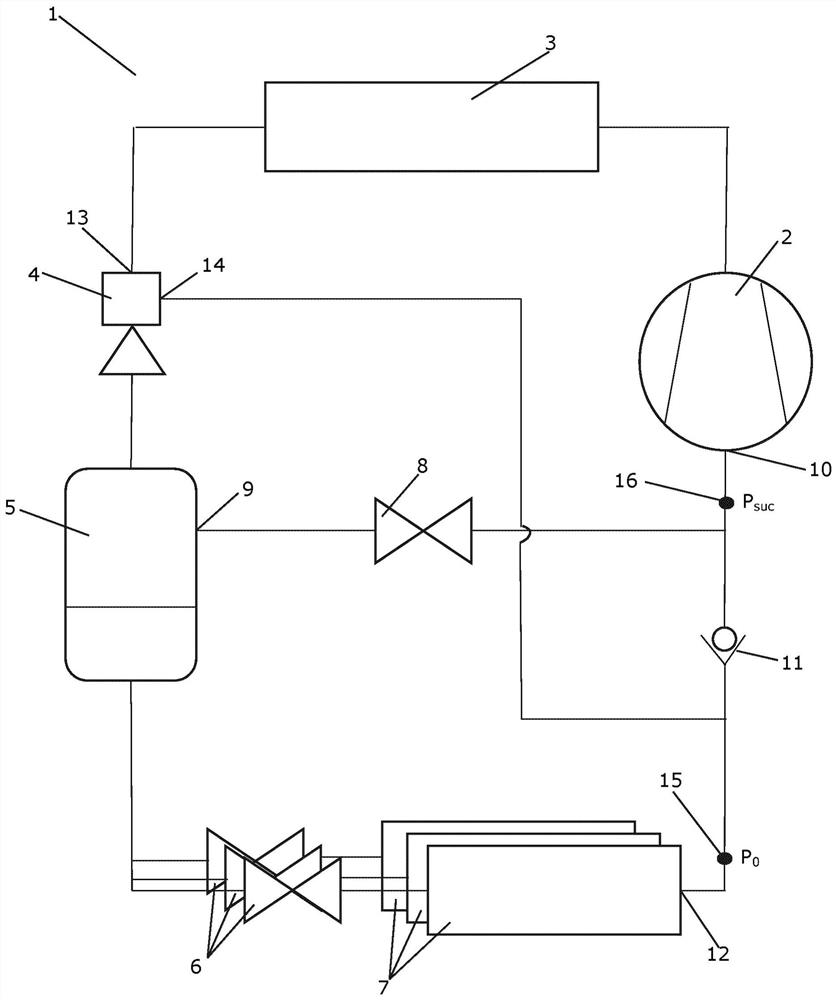

[0056] figure 1 is a diagrammatic view of a vapor compression system 1 operating according to a method according to a first embodiment of the invention. The vapor compression system 1 comprises a compressor unit 2 , a heat rejection heat exchanger 3 , an ejector 4 , a receiver 5 , three expansion devices 6 and three evaporators 7 arranged in a refrigerant path. The evaporators 7 are fluidly arranged in parallel, and each of the expansion devices 6 supplies refrigerant to one of the evaporators 7 . A bypass valve 8 interconnects the gas outlet 9 of the receiver 5 with the inlet 10 of the compressor unit 2 . A check valve 11 is arranged in the refrigerant path between the outlet 12 of the evaporator 7 and the inlet 10 of the compressor unit 2 .

[0057] The refrigerant flowing in the refrigerant path is compressed by the compressor unit 2 . The compressed refrigerant is supplied to the heat rejection heat exchanger 3, where heat exchange with the environment takes place in su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com