Internal throwing type bench blasting method

A step blasting and internal throwing technology, which is applied in blasting, earth-moving drilling, ground mining, etc., can solve the problems of easily destroying transportation channels, smashing workers and machines on the lower layers, and reducing throwing and the effect of explosive gas. , the effect of reducing the length of the blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Based on the blasting process of the inner throwing type step in embodiment 1, the following steps are designed:

[0053] Step 1: Clean up the working surface 4 and prepare for hole layout;

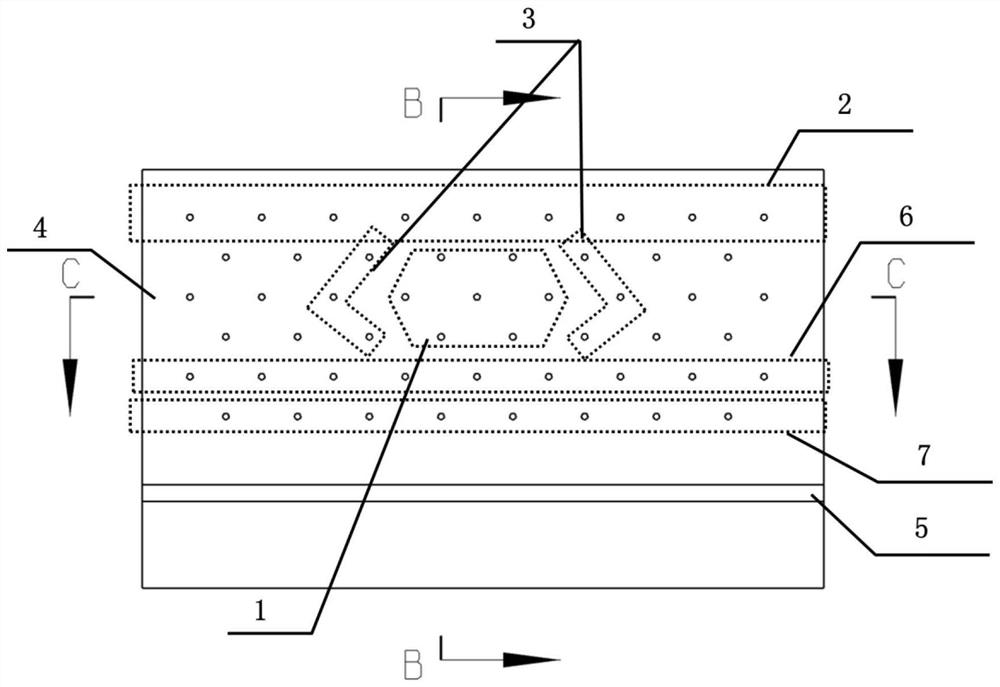

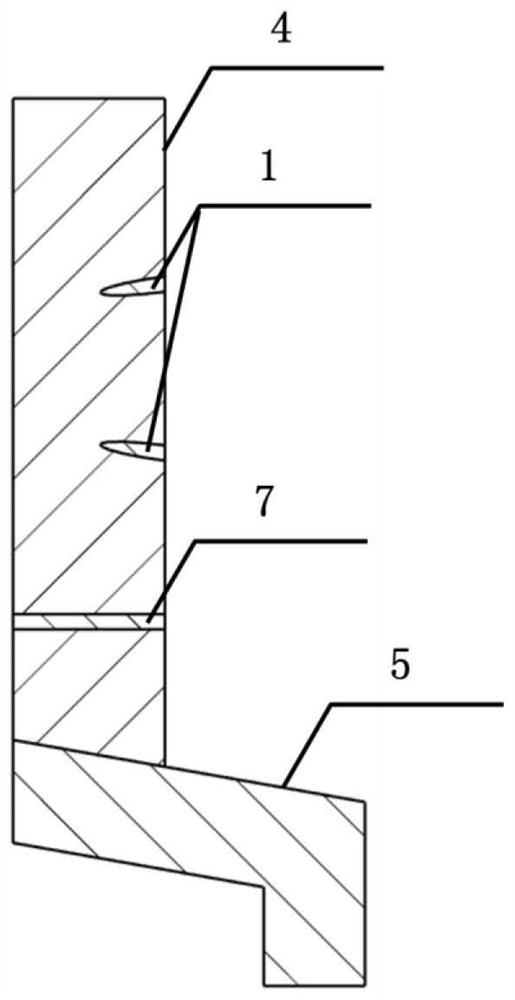

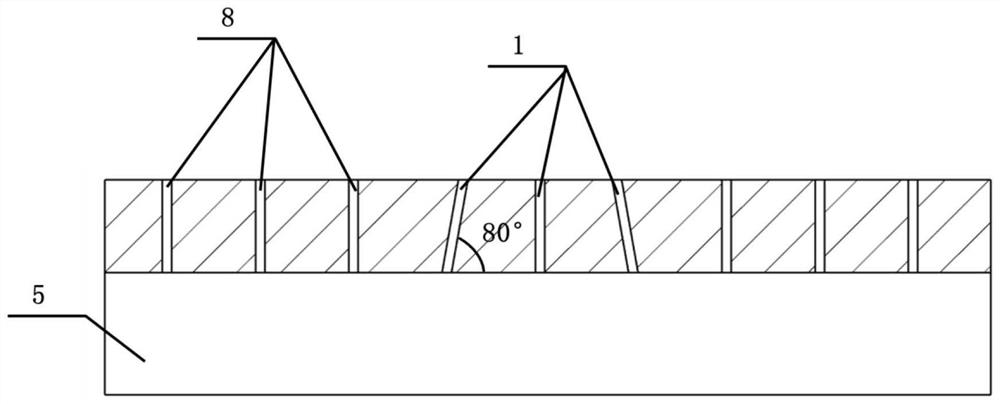

[0054] Step 2: Calibrate the blasthole position of the inner throwing hole 1 on the working face 4;

[0055] Preferably, there are 7 internal blasting holes 1, the distance between adjacent internal blasting holes 1 is 4.5m, the diameter is 150mm, the wedge-shaped cutting method is adopted, the angle with the working face 4 is 80 degrees, and the depth of the blasting hole is 15m.

[0056] Step 3: Calibrate the blasthole position of the peripheral pre-splitting hole 2 on the working face, and the peripheral pre-splitting hole 2 is located on the top contour line of the earthwork to be blasted;

[0057] Preferably, the distance between the adjacent peripheral pre-splitting holes 2 is 4.5m, the row spacing of the peripheral pre-splitting holes 2 and the auxiliary holes 8 is 5m, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com